Adjusting gibs, Notice – Grizzly G0517g User Manual

Page 27

Model G0517 Mill/Drill

-25-

Oil Fittings

Oil fittings are located on the tops of each

handwheel and on each side of the base. Lubricate

these fittings with ISO 68 or SAE 20W oil by

depressing the ball with an oil can nozzle and

squirting once or twice.

Figure 46. Handwheel oil fittings.

Figure 47. Oil fittings on left-side of table.

Figure 48. Oil fittings on right-side of table.

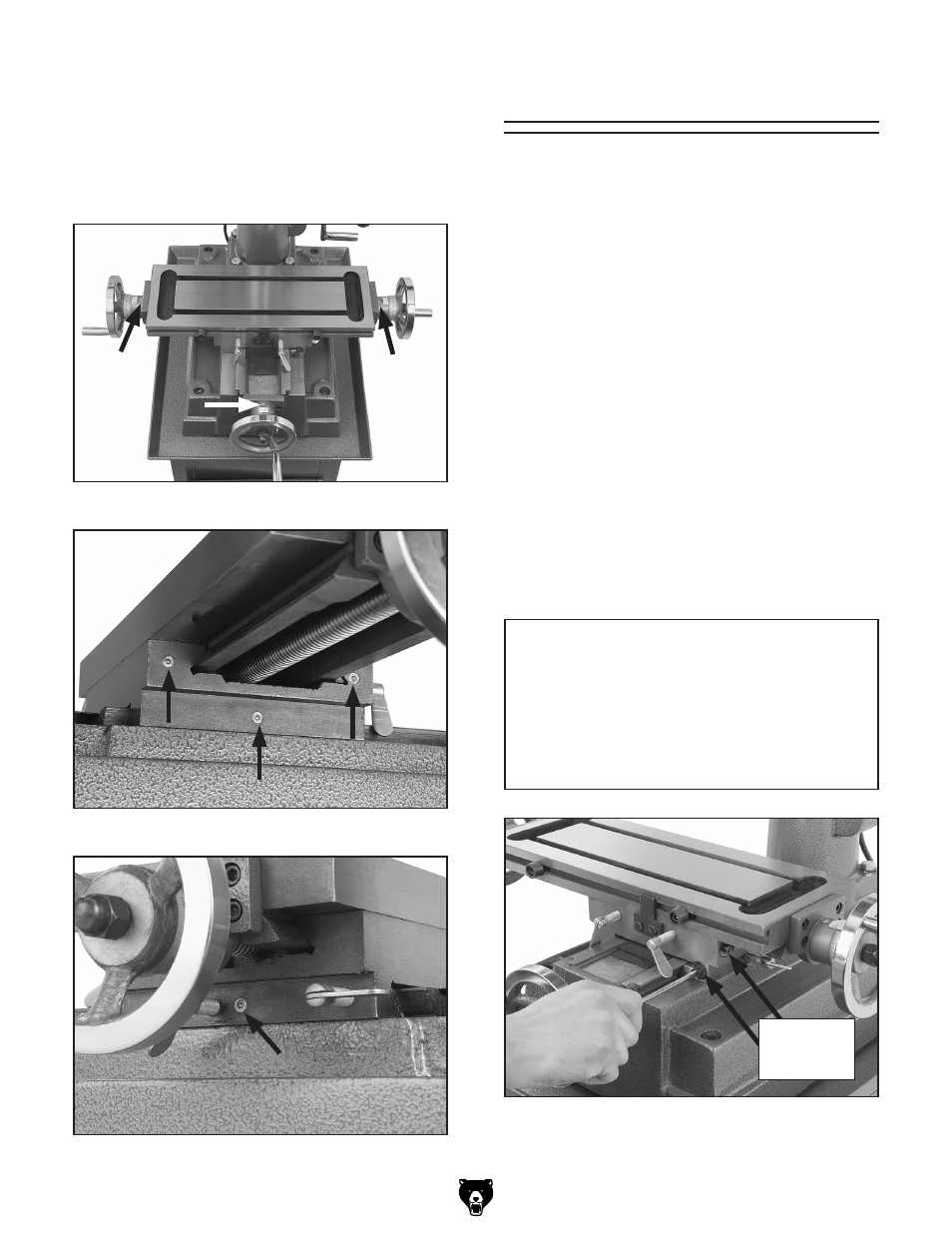

Adjusting Gibs

Figure 49. Gib adjustment.

The gibs control play in the longitudinal and cross

feed table movement; they are pre-adjusted at the

factory and typically need no adjustments until

the machine is well used. If table movement is too

tight, make sure the locks are fully released. Next,

make sure the bedways are thoroughly cleaned of

rust preventative and lubricated with oil.

Both the longitudinal table and the cross feed

table have gib adjustment screws (see

Figure 49

for the location). Turn the gib adjustment screw

clockwise to tighten the gib or turn counterclock-

wise to loosen the gib.

To adjust the gibs:

1. Turn the gib screw one full turn in the neces-

sary direction for tightening or loosening.

2. Test the gib tension by turning the handwheel

and moving the table back and forth. Repeat

Step 1 as necessary.

NOTICE

When adjusting gibs, the goal is to remove

unnecessary sloppiness without causing

the slides to bind. Loose gibs may cause

poor finishes on the workpiece and may

cause undue wear on the slide. Over-tight-

ened gibs may cause premature wear.

Gib

Adjustment

Screws