Milling speed – Grizzly G0517g User Manual

Page 23

Model G0517 Mill/Drill

-21-

Milling Speed

Closely follow the proper cutting speed—with a

reasonable feed speed—to reduce undue strain

on all moving parts and increase operator safety.

Prior to machining, you need to determine the

best speed to cut your workpiece, and then set

that speed on the machine.

To determine the needed speed for milling:

1. Use the table in Figure 32 to determine the

cutting speed required for the material of your

workpiece.

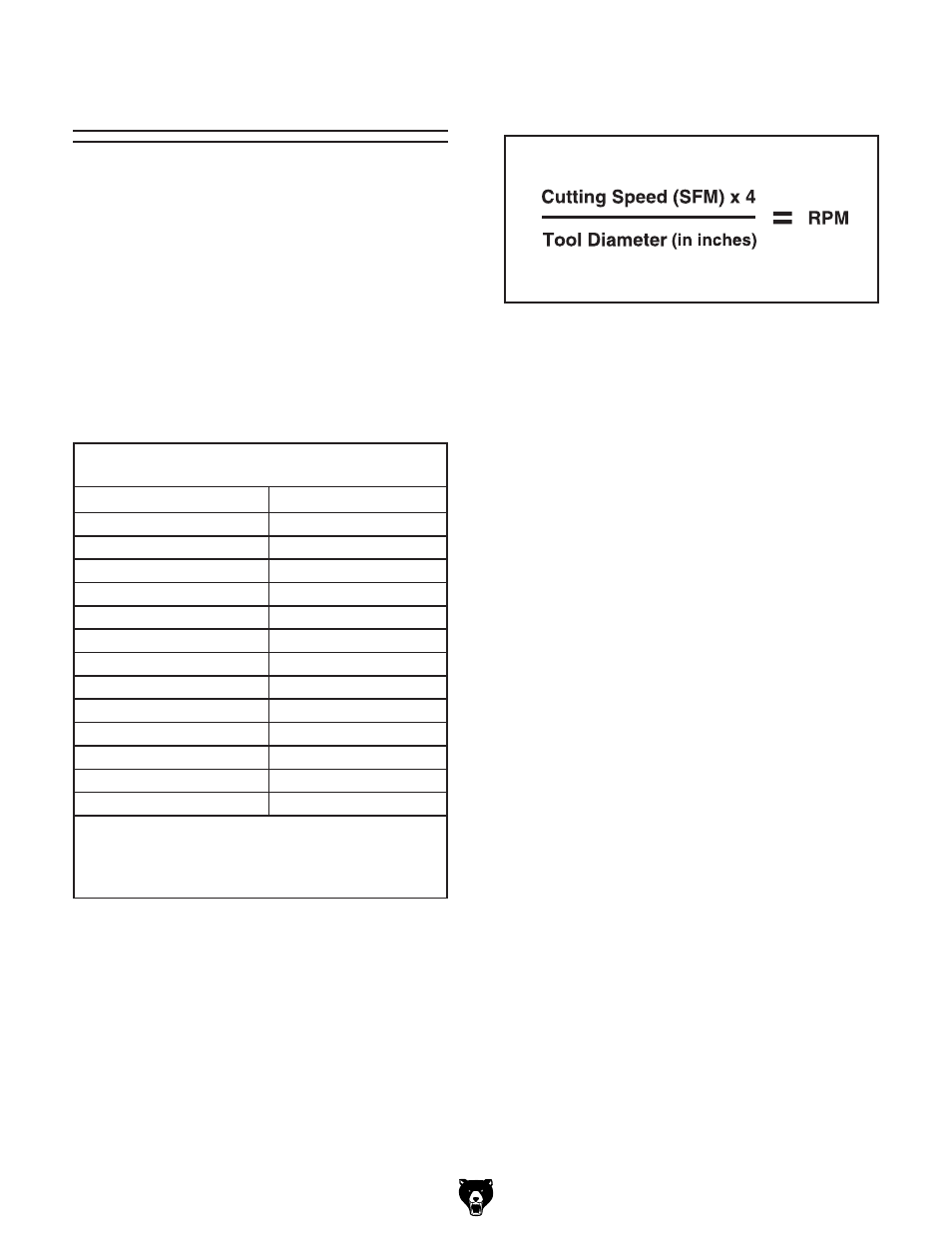

Cutting Speeds for High Speed Steel (HSS)

Cutting Tools

Workpiece Material

Cutting Speed (SFM)

Aluminum & alloys

300

Brass & Bronze

150

Copper

100

Cast Iron, soft

80

Cast Iron, hard

50

Mild Steel

90

Cast Steel

80

Alloy Steel, hard

40

Tool Steel

50

Stainless Steel

60

Titanium

50

Plastics

300-800

Wood

300-500

Note:

For carbide cutting tools, double the cut-

ting speed. These values are a guideline only.

Refer to the

MACHINERY'S HANDBOOK for

more detailed information.

Figure 32

. Cutting speed table for HSS cutting

tools.

3. Use the formula in Figure 33 to determine

the needed speed for your operation:

Figure 33. Speed formula for milling.

Note: Always round to the closest RPM given

on the spindle speed chart.

Example 1

You have a piece of aluminum stock, and

you are using a

1

⁄

2

" diameter HSS cutting

tool.

Step 1:

300 (SFM from chart) x 4 = 1200

Step 2:

1200 / .5" (Diameter of cutting tool) =

2400 RPM

Result:

The best speed for this workpiece is 2400

RPM.

Example 2

You have a piece of stainless steel, and

you are using a 1" diameter carbide cutting

tool.

Step 1:

60 (SFM from chart) x 2 (for carbide tool) =

120

Step 2:

120 (determined SFM) x 4 = 480

Step 3:

480 / 1" (Diameter of cutting tool) = 480

RPM

Result:

The best speed for this workpiece is 480

RPM.

2. Measure the diameter of your cutting tool in

inches.