Installation/operation – Graco Inc. 235465 User Manual

Page 4

4

308237

Installation/Operation

System Requirements.

WARNING

Keep the walletĆsized warning card provided with

this gun with the operator at all times. The card

contains important treatment information should

an injection injury occur. Additional cards are

available at no charge from Graco Inc.

WARNING

Be sure your system has a bleedĆtype master air

valve (pneumatic pumps only) and a pressure

drain valve. These accessories help reduce the

risk of serious bodily injury, including fluid injecĆ

tion, splashing in the eyes or on the skin, or injury

from moving parts, if you are adjusting or repairing

the pump or gun.

1. The bleedĆtype master air valve (airĆpowered

pumps only) relieves air trapped between this

valve and the pump after the air regulator is shut

off. Trapped air can cause the pump to cycle

unexpectedly.

2. The pressure drain valve assists in relieving fluid

pressure in the displacement pump, hose and

gun: triggering the gun to relieve pressure may

not be sufficient.

3. Strain the fluid you are spraying if it contains

particles which could clog the spray tip.

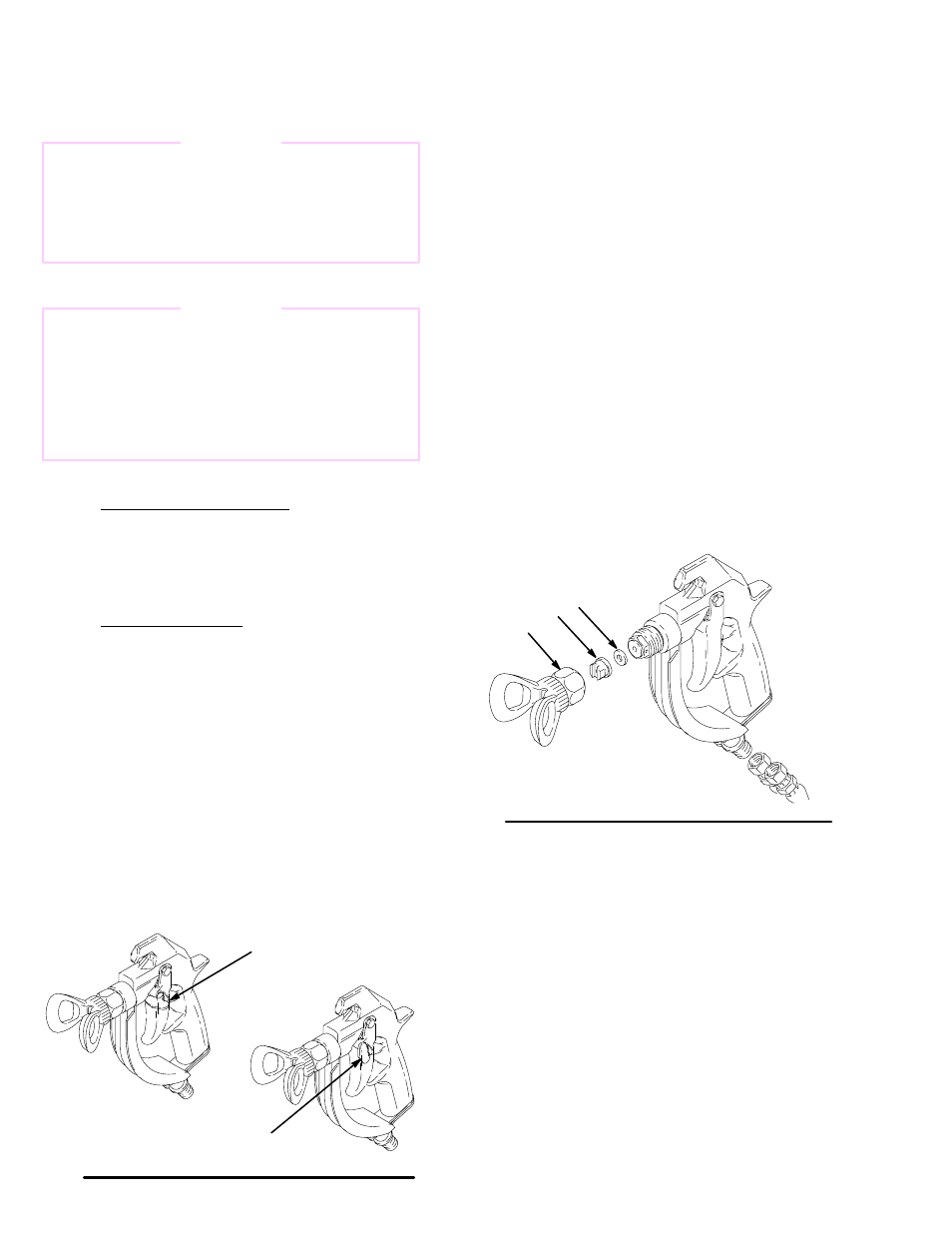

How to Use the Trigger Safety Latch

1. To engage the trigger safety latch, turn the latch

(A) to a right angle with the gun body. See Fig. 1.

2. To disengage the trigger safety latch, push the

latch (A) out and turn it parallel with the gun body.

Fig. 1

ENGAGED

DISENGAGED

01484

How to Use the Gun.

1. If an accessory inĆline filter is used, connect it to

the grounded fluid supply hose. Connect the

supply hose to one gun port and connect an elecĆ

trically conductive, fluid return hose to the other

port.

2. With no tip installed, start the pump. Flush the

pump according to the instructions supplied with

it. Prime the system with the fluid.

3. Follow the Pressure Relief Procedure on page

2. Be sure the trigger safety latch is engaged. See

Fig. 1.

4. Unscrew the tip guard (1) and install the tip (A)

and the gasket (2d) in the nut of the tip guard.

Screw the assembly firmly onto the gun. Tighten

the assembly with a wrench. See Fig. 2.

NOTE: If the gasket (2d) is not installed, the gun

will leak.

Fig. 2

01483

1

A

2d

5. Start the pump.Adjust the back pressure valve or

the RestrictĆAĆFlo valve in the circulating system

return line. Adjust the fluid pressure until the

spray is completely atomized. Use the lowest

pressure necessary to get the desired results.

Higher pressure may not improve the spray

pattern and will cause premature tip wear and

pump wear.

6. If adjusting the pressure does not give a good

spray pattern, follow the Pressure Relief ProceĆ

dure on page 2 and then try another tip size.

7. Use a fullĆopen, fullĆclose triggering action. Hold

the gun about 14 in. (350 mm) from and at right

angles to the work surface. Don't swing the gun

in an arc. Practice to find the best length and

speed of stroke.