Displacement pump, Warning, Caution – Graco Inc. 232632 User Manual

Page 15

308870

15

Displacement Pump

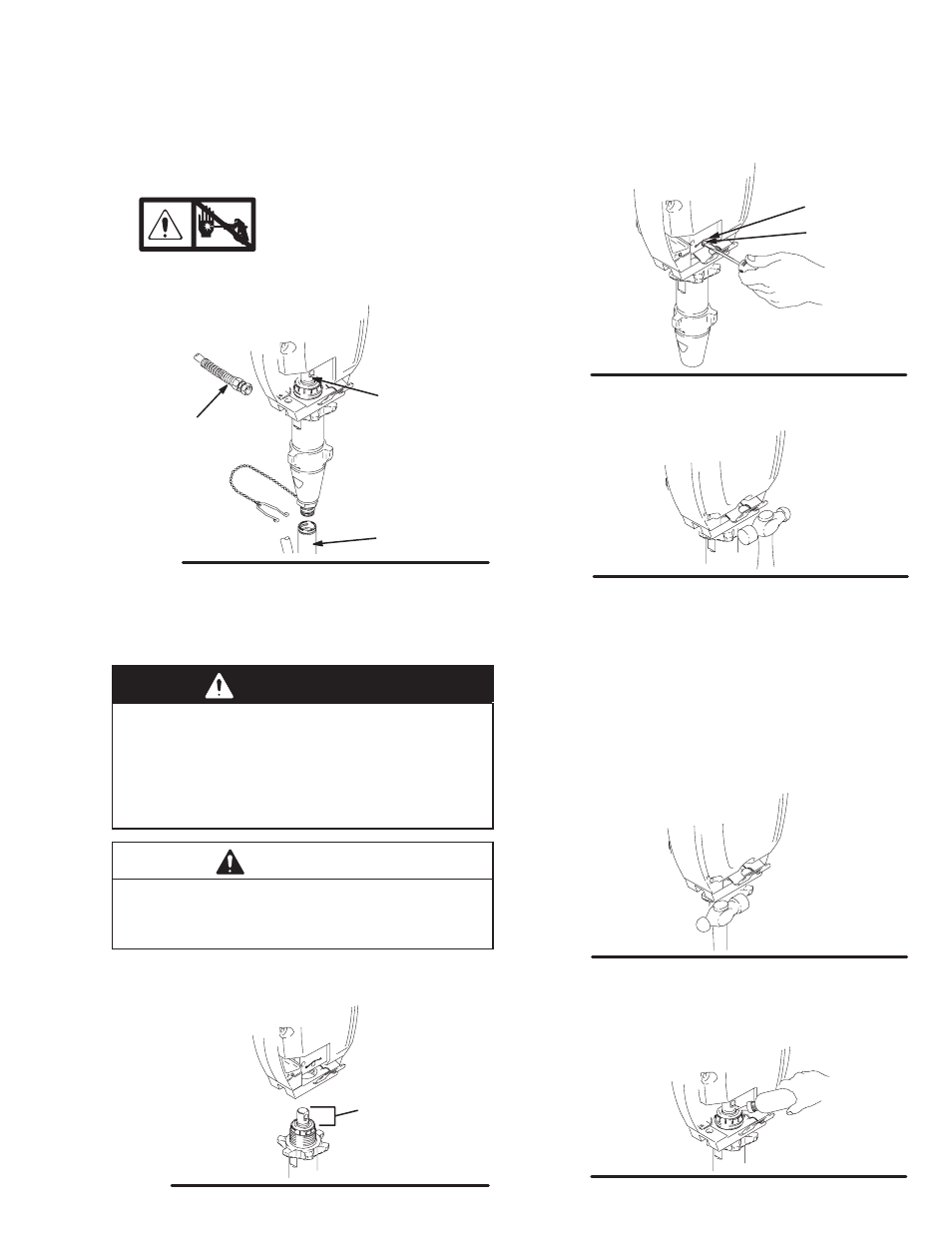

Removal

1. Flush pump.

2. Fig. 16. Cycle pump with piston rod (222) in lowest

position.

3.

Relieve pressure

; page 4.

4. Fig. 16. Remove suction tube (30) and hose (33).

Fig. 16

222

33

30

9024A

5. Fig. 17. Use screwdriver to push out pump

pin (101).

Fig. 17

101

9019A

230

6. Fig. 18. Loosen locknut by hitting firmly with a

20 oz (maximum) hammer. Unscrew pump.

9022A

Fig. 18

Repair

See manual 308798 for pump repair instructions.

Installation

WARNING

If pin works loose, parts could break off due to

force of pumping action. Parts could project

through the air and result in serious injury or prop-

erty damage. Make sure pin (101) and retaining

clip (230) are properly installed. Clip must engage

groove in pin.

CAUTION

If the pump locknut loosens during operation, the

threads of the bearing housing will be damaged.

Make sure locknut is properly tightened.

1. Fig. 19. Pull piston rod out 1.0 in. Screw in pump

until holes in housing plates and piston rod align.

Fig. 19

1.0 in.

9020A

2. Fig. 17. Push pin (101) into hole until retaining clip

(230) engages pump pin groove.

Fig. 20. Screw jam nut down onto pump until nut

stops. Screw pump up into pump plate until it stops.

Back off pump one full turn and align pump outlet to

back. Tighten jam nut by hand, then tap 1/8 to 1/4 turn

with a 20 oz (maximum) hammer to approximately

75" 5 ft–lb (102 Nm).

9021A

Fig. 20

Fig. 21. Fill packing nut with Graco TSL until fluid flows

onto the top of seal.

Fig. 21

9023A