Unpainted cast iron, Schedule, Lubrication – Grizzly G9749 User Manual

Page 28

-26-

G9749 Variable Speed Drill Press

SECTION 6: MAINTENANCE

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person-

al injury.

Protect the unpainted cast iron surfaces on the

table by removing vises and fixtures daily and by

wiping the table clean after every use.

Keep tables rust-free with regular applications of

products like G96

®

Gun Treatment or Boeshield

®

T-9. See below for Grizzly model numbers:

G2871—Boeshield

®

T-9 12 oz Spray

G2870—Boeshield

®

T-9 4 oz Spray

H3788—G96

®

Gun Treatment 12 oz Spray

H3789—G96

®

Gun Treatment 4.5 oz Spray

Unpainted Cast Iron

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check:

•

Drill press is completely powered down at the

end of use.

•

Excess cutting fluids and chips have been

removed and unpainted surfaces are dry and

protected.

•

Floor mounting bolts are secure.

•

Drill press is clean and lubricated.

•

Examine wiring for damage or wear.

•

Check for any other unsafe condition.

Schedule

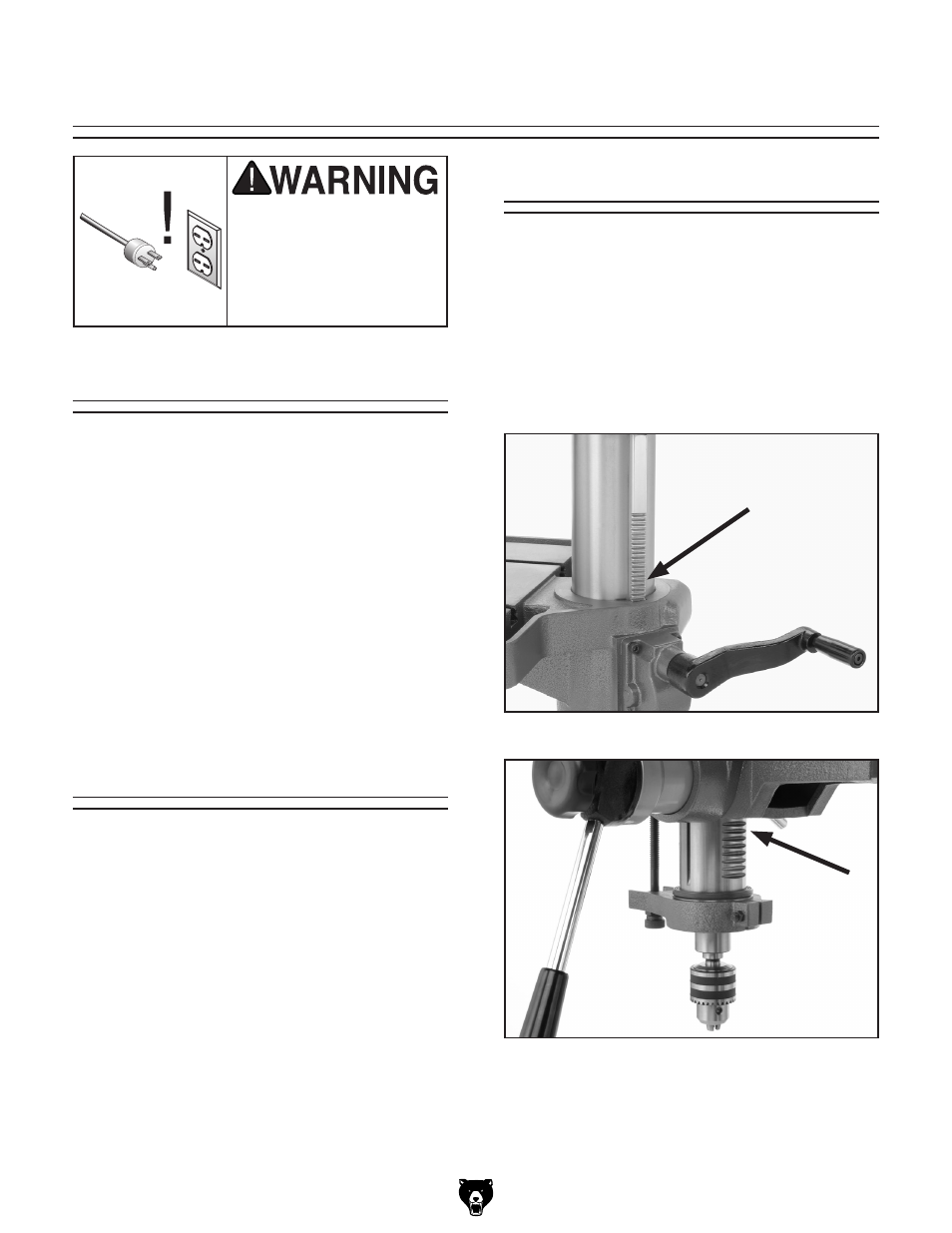

The quill and table use a rack and pinion assem-

bly for movement. To ensure a smooth operation

and a long life of these rack and pinion systems,

lubricate as needed depending upon use.

Brush a small amount of multi-purpose grease on

the rack near the pinion (see

Figure 28 & 29).

Move the table or quill up and down to distribute

the grease.

Lubrication

Figure 28. Table rack lubrication point.

Note: All other bearings are lubricated and sealed

at the factory, and do not need further lubrica-

tion.

Figure 29. Quill rack lubrication point.