Repair – Graco Inc. Series E User Manual

Page 12

12

307–760

REPAIR

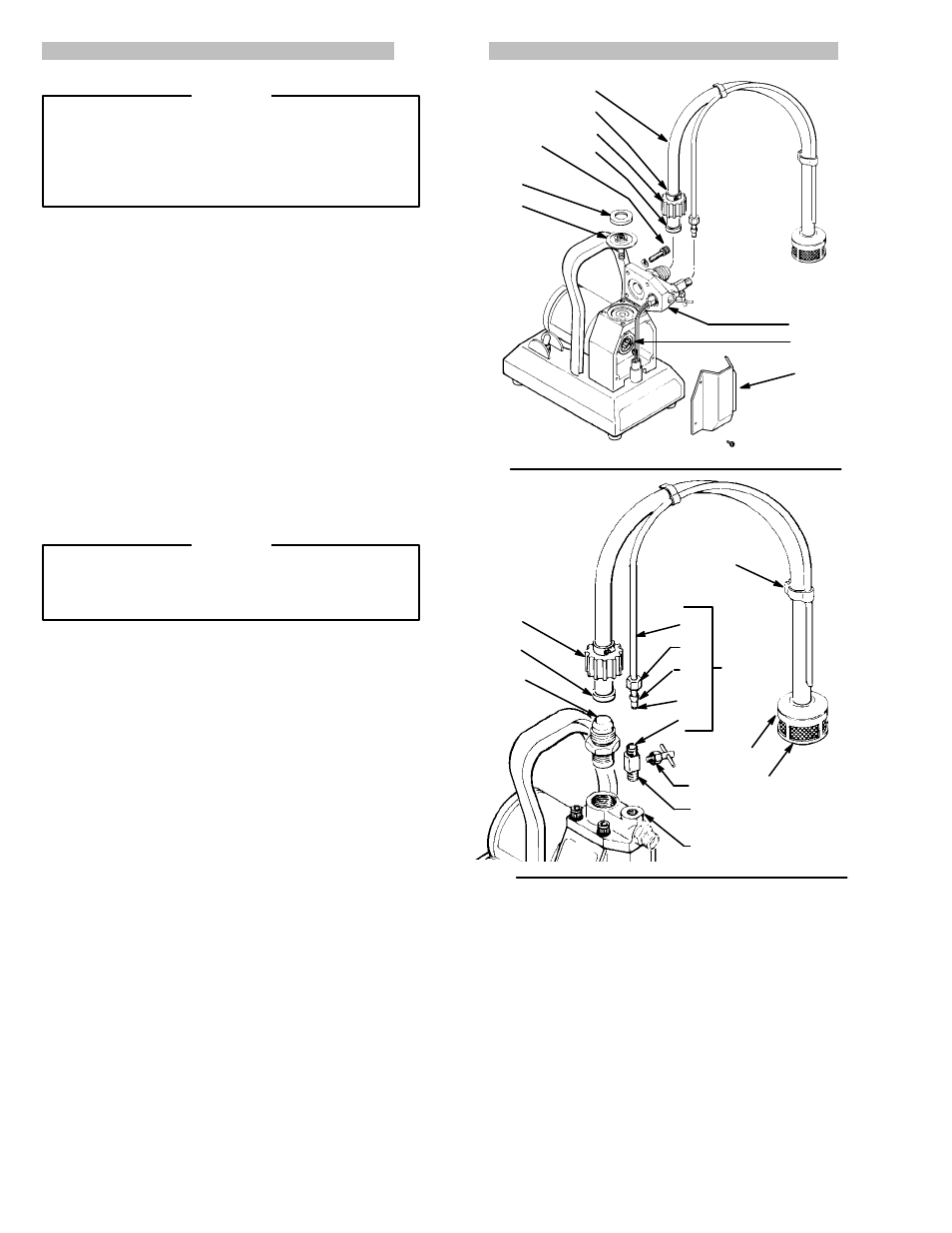

Diaphragm

(See Fig 14)

CAUTION

To avoid leaks and costly pump damage, replace the

diaphragm whenever the pump housing (9) is re-

moved or after each 100 hours of use, whichever

comes first. During use, small grooves are formed in

the diaphragm which cannot be realigned properly.

1. Remove the screws (15). Tip the pump housing (9)

back, being careful not to damage the wires. Re-

move the front cover plate (23).

2. Check the diaphragm guide (11), and replace it if

necessary. Clean the pump housing thoroughly, and

then lay the flat side of the guide into the housing and

use your fingers to press it evenly into place.

3. Unscrew the diaphragm (17).

4. Use a soft bristle brush to clean the top of the con-

necting rod and housing. Gently clean the bottom of

the pump housing (9), avoiding damage to the dia-

phragm grooves.

5. Check the rod, motor bearing and eccentric for

paint. If there is any paint or damage, clean or re-

place the connecting rod assembly as explained on

page 13.

CAUTION

To ensure the diaphragm will work properly, do not

turn the diaphragm more than 1/2 turn when torqu-

ing it.

6. Screw the new diaphragm (17) into the connecting

rod just until it bottoms out. Then turn it 1/4 to 1/2 turn

(2.7–3.6 N.m [6–8 in–lb]).

7. Apply thread lubricant to the screws (15) and install

them with the lockwashers in the pump housing.

Torque the screws a little at a time, oppositely and

evenly, to 9.8 N.m (85 in–lb).

8. Spin the motor shaft (D) to be sure it turns freely.

9. Reinstall the front cover (23).

Priming Valve & Tube

(See Fig 15)

NOTE: Each new priming valve kit includes a priming

tube and fittings.

1. Unscrew the nut (E) of the priming valve (10a), and

then unscrew the stem of the handle.

2. Unscrew the priming valve (10a).

3. Wrap the threads of the priming valve with PTFE

R

tape, and then screw it snugly into the pump housing.

The valve handle should be parallel with the angled

edge of the housing to avoid interference with the in-

let or outlet valves.

4. Slide the nut (10d) and ferrule (10c) onto the tube

(10e), and then install the tube support (l0b) in the

end of the tube. Screw the nut onto the priming valve,

which will seat the ferrule.

5. Screw the stem of the handle (E) onto the priming

valve until it bottoms, then back it out two turns.

Screw the nut hand tight onto the priming valve, then

tighten the stem into the valve.

44

47

45

46

10d

10c

Fig 14

Fig 15

10e

10b

10a

E

WRAP WITH

PTFE TAPE

45

46

1

52

48

49

9

10

11

17

9

D

23

15,16

LUBRICATE

THREADS

TORQUE TO

85 in-lb

(9.6 N.m)

Suction Tube (See Fig 15)

1. Unscrew the hose nut (45). Remove the hose camp

(47). Slit the suction hose to free the nipple (46).

2. With the nipple (46) inserted through the nut (45),

dampen the new hose (44) with warm water and

press the hose over the nipple. Screw the nut onto

the inlet valve housing, and then press the hose fur-

ther onto the nipple. Leave about a 1/8 in. (3 mm) gap

between the nut and hose end.

3.

Install the hose camp (47) and tighten snugly.

4. Remove the filter housing (48) and strainer (49) and

install them on the new hose. Dampen the hose with

warm water to ease assembly.