Bevel cutting – Grizzly Extreme Series Jointer G9953ZXF User Manual

Page 32

-30-

Extreme series Jointer (Mfg. since 9/11)

bevel cutting

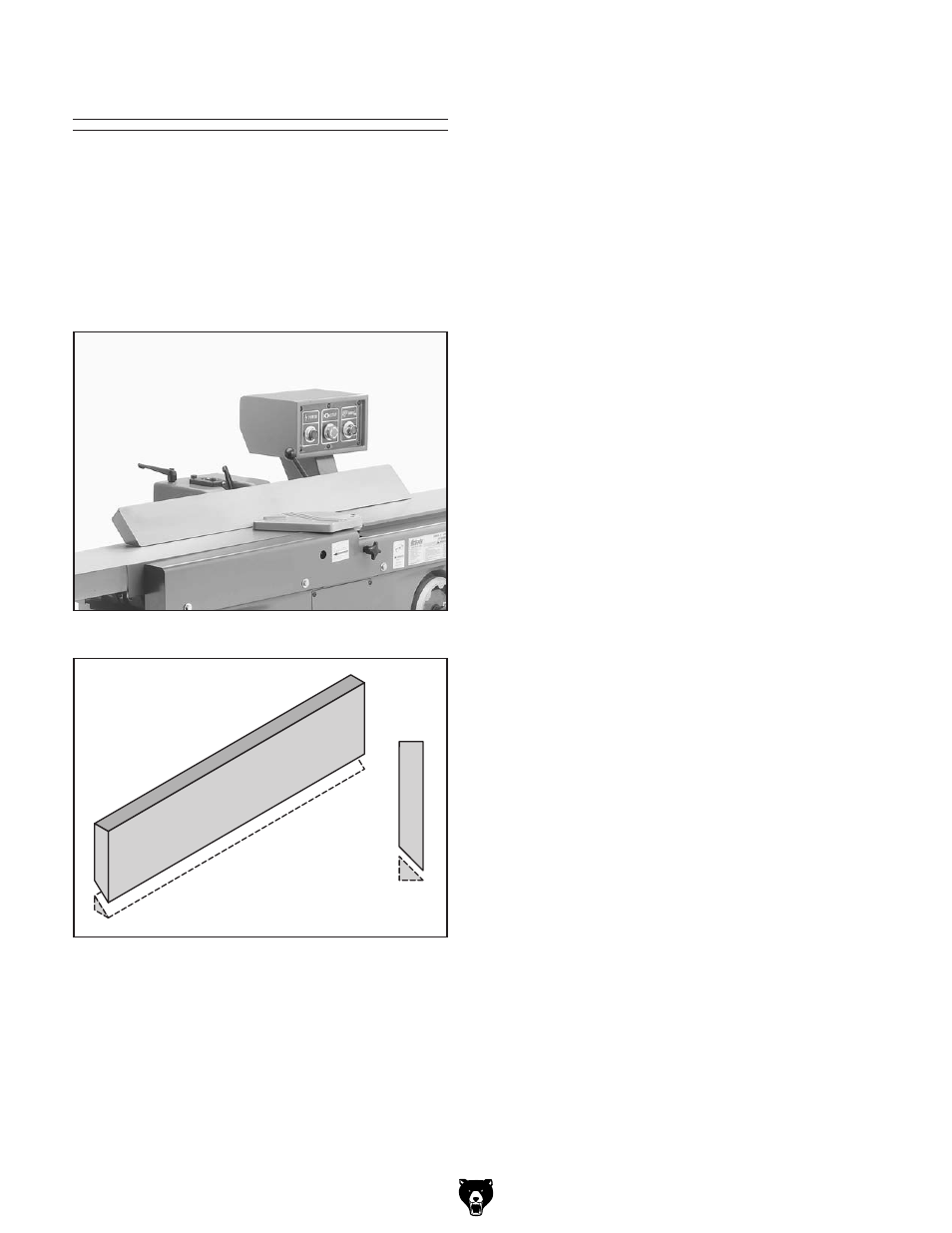

the purpose of bevel cutting on the jointer is to

cut a specific angle of the workpiece edge (see

Figures 44–45.

your jointer has fence stops that can be set at

90° or 45°. if your operation requires a different

angle, the fence can be locked in place anywhere

between these angles.

Figure 44. Fence setup for a bevel cut of 45°.

Figure 45. illustration of bevel cutting results.

To bevel cut on the jointer:

1. disCoNNECt JoiNtEr FroM poWEr!

2. Make sure you read and follow the Safety

Instructions beginning on page 6 and the

Stock Inspection & Requirement rules

beginning on

page 26.

3. Verify that the outfeed table height is properly

set (refer to

Setting Outfeed Table height

on

page 19).

4. set the depth of cut for your operation and

the fence to the required angle.

Note: We suggest

1

⁄

16

"–

1

⁄

8

" depth of cut for

bevel cutting, and a more shallow depth for

hardwood species or for wide stock.

5. if your workpiece is cupped or warped, place

it so the concave side is face down on the

infeed table.

6. Connect the jointer to power and turn it ON.

7. With a push block in each hand, press

the workpiece against the infeed table and

the fence with firm pressure, then feed the

workpiece over the cutterhead.

Note: When your leading hand comes within

4" of the cutterhead, lift that push block up

and place it on the workpiece portion that is

on the outfeed table. Now, focus the down-

ward pressure with the leading hand while

feeding, then repeat the same action with

your trailing hand when it comes within 4" of

the cutterhead. Keep your hands safe! DO

NOT allow them to get any closer than 4" to

the cutterhead.

8. repeat Step 7 until the bevel cut is satisfac-

tory.