Recommended adjustments – Grizzly Extreme Series Jointer G9953ZXF User Manual

Page 25

Extreme series Jointer (Mfg. since 9/11)

-23-

4. Verify that the outfeed table height is properly

set (refer to

Setting Outfeed Table height

on

page 19).

5. Connect the machine to the power source.

6. Verify that the machine is operating correctly

by pushing the oN button.

—When operating correctly, the machine

runs smoothly with little or no vibration or

rubbing noises.

— investigate and correct strange or unusual

noises or vibrations before operating the

machine further. always disconnect the

machine from power when investigating or

correcting potential problems.

7. if equipped on your jointer, rotate the

cutterhead brake handle to stop the machine

and cutterhead.

— if the machine does not turn

OFF, use the

stop button to turn it

OFF and immediately

disconnect power to the machine. the

cutterhead brake feature is not working

correctly. this safety feature must work

properly before proceeding with regular

operations. Call tech support for help.

8. Model G9953ZXF Only: press the stop but-

ton to turn the machine

OFF and observe the

cutterhead rotation.

For your convenience, the adjustments listed

below have been performed at the factory and

no further setup is required to operate your

machine.

however, because of the many variables involved

with shipping, we recommend that you at least

verify the following adjustments to ensure the best

possible results from your new machine.

step-by-step instructions for these adjustments

can be found in the

SERvIcE section, beginning

on

page 36.

Factory adjustments that should be verified:

•

table parallelism (

page 44).

•

Model g9860 & g9953 Knife height (

page

39).

Recommended

adjustments

— if the cutterhead is rotating counterclock-

wise (from right-to-left), the motor is wired

out of phase. disconnect the jointer from

power, then switch any two hot leads com-

ing from the power source.

9. if not already done, use the stop button to

turn the machine

OFF.

10. Without resetting the stop switch, press

the oN button. the machine should not

start.

—if the machine does not start, the stop but-

ton safety feature is working correctly. the

Test Run is complete.

—if the machine does start (with the stop

button pushed in), immediately disconnect

power to the machine. the stop button

safety feature is not working correctly. this

safety feature must work properly before

proceeding with regular operations. Call

tech support at (570) 546-9663 for help.

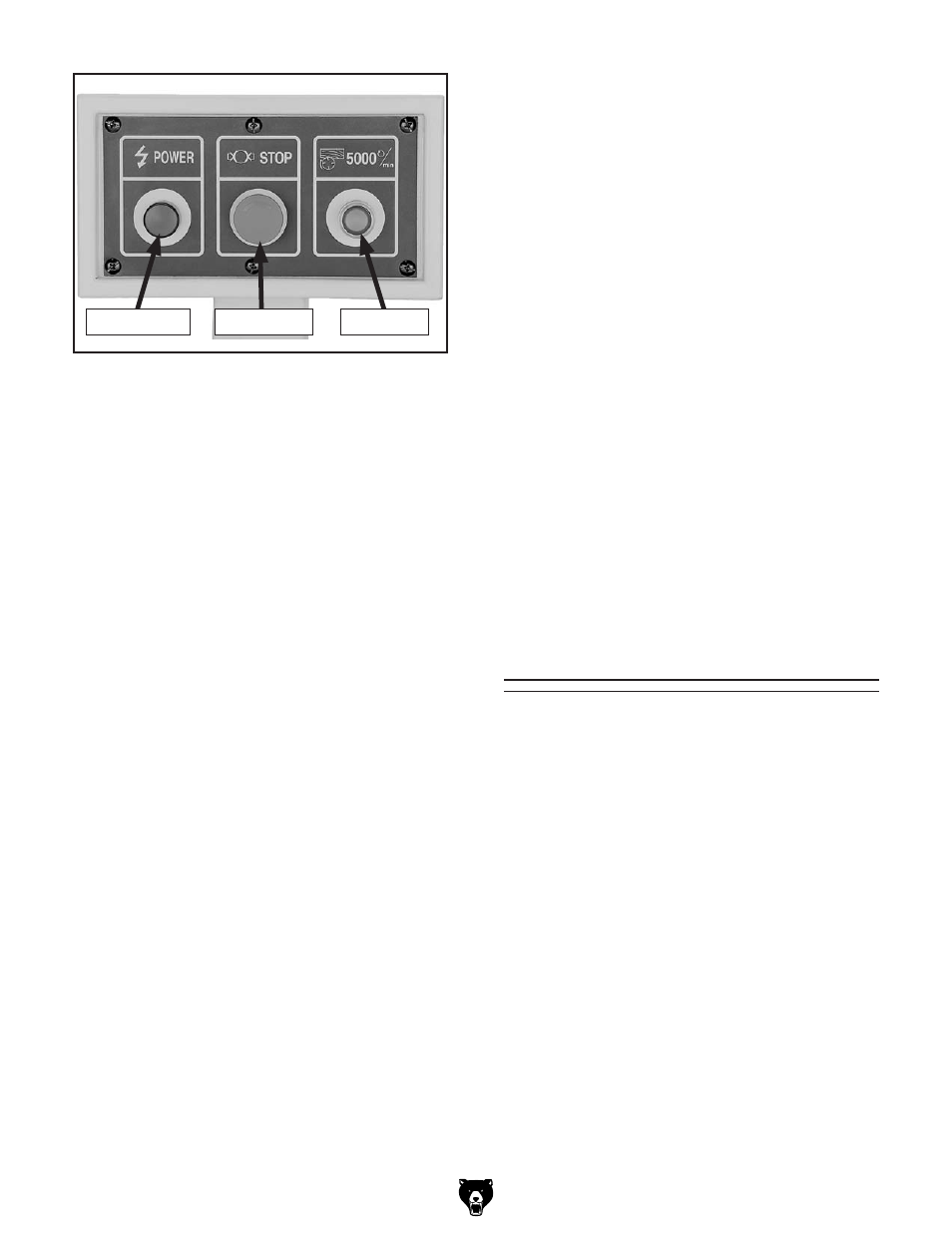

Figure 28. Control panel.

power lamp

stop Button

oN Button