Squaring stock – Grizzly Extreme Series Jointer G9953ZXF User Manual

Page 29

Extreme series Jointer (Mfg. since 9/11)

-27-

Squaring Stock

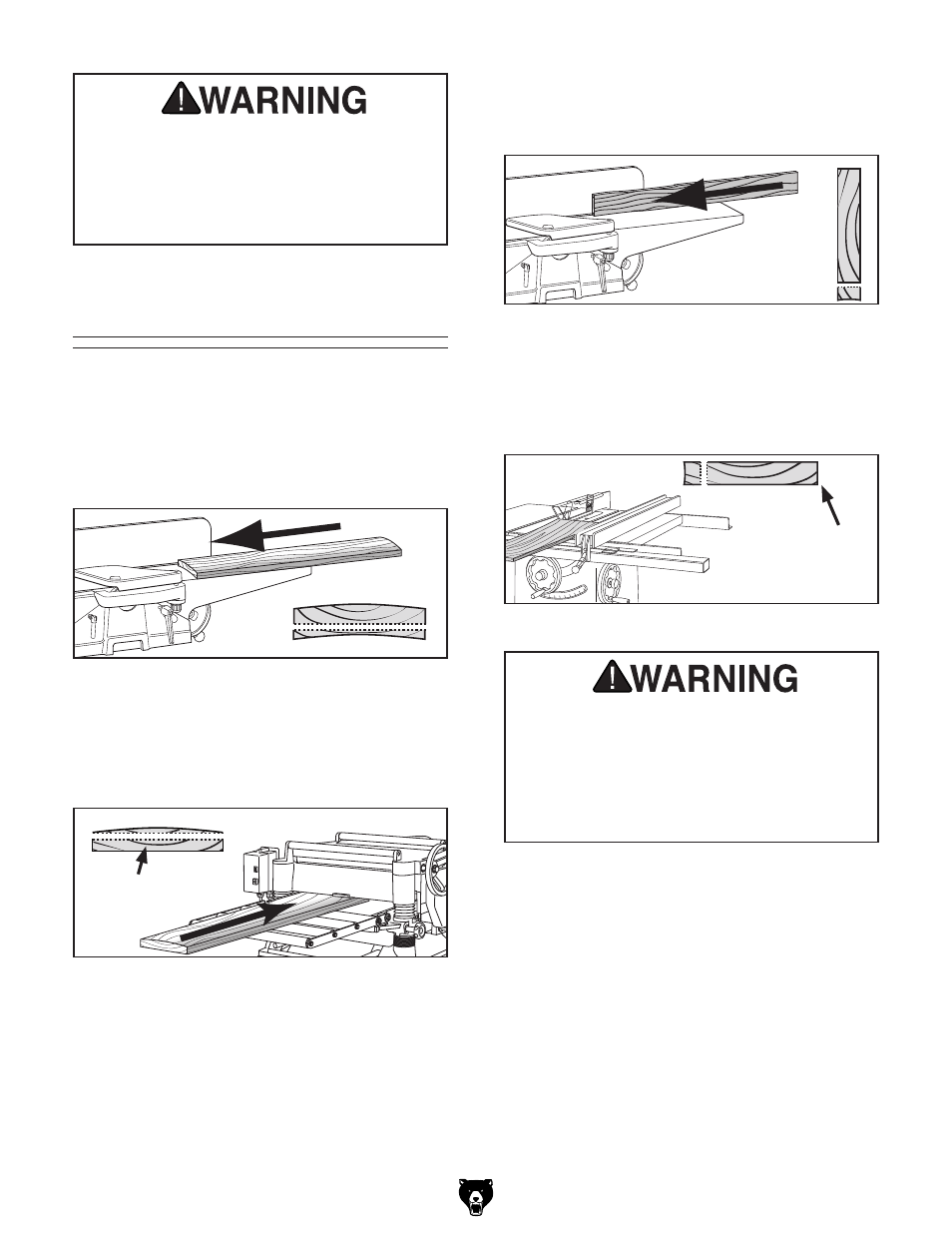

before turning the jointer ON, make sure the

outfeed table height is properly set (refer to

page 19 for detailed instructions) to avoid

workpiece kickback and to ensure good

results. Kickback of the workpiece could

cause serious personal injury!

Squaring stock involves four steps performed

in the following order:

1. Surface plane on the Jointer: the concave

face of the workpiece is surface planed flat

with the jointer (see

Figure 36).

Figure 36. surface planing on the jointer.

2. Surface plane on a Thickness planer:

the opposite face of the workpiece is sur-

face planed flat with a thickness planer (see

Figure 37).

previously

surface

planed Face

Figure 37. surface planing on a thickness

planer.

3. Edge Joint on the Jointer: the concave

edge of the workpiece is jointed flat with the

jointer (see

Figure 38).

Figure 38. Edge jointing on the jointer.

4. Rip cut on a Table Saw: the jointed edge

of the workpiece is placed against the table

saw fence and the opposite edge is cut off

(see

Figure 39).

previously

Jointed Edge

Figure 39. rip cutting on a table saw.

Making adjustments to the jointer while the

machine is ON greatly increases the risk to

the operator from the rotating cutterhead.

aLWayS make sure the jointer is OFF and

disconnected from power before performing

adjustments, maintenance, or service on the

machine!