Operand summary - electronic cam, Example, Electronic cam – Galil DMC-2X00 User Manual

Page 109: Example electronic cam

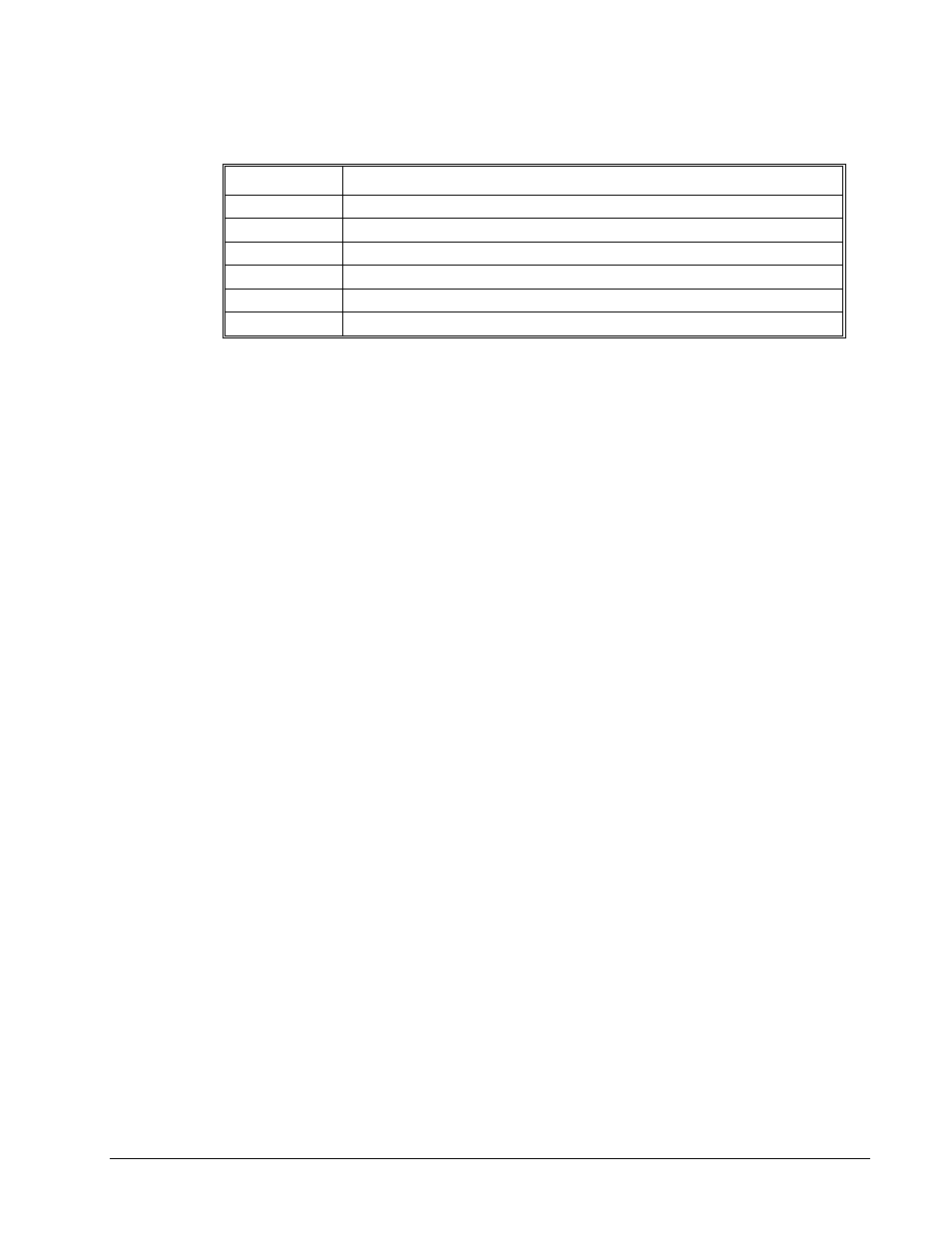

Operand Summary - Electronic CAM

command description

_EB

Contains State of ECAM

_EC

Contains current ECAM index

_EGa

Contains ECAM status for each axis

_EM

Contains size of cycle for each axis

_EP

Contains value of the ECAM table interval

_EQx

Contains ECAM status for each axis

Example

Electronic CAM

The following example illustrates a cam program with a master axis, C, and two slaves, A and B

Instruction Interpretation

#A;vl=0

Label; Initialize variable

PA 0,0;BGAB;AMAB

Go to position 0,0 on A and B axes

EA C

C axis as the Master for ECAM

EM 0,0,4000

Change for C is 4000, zero for A, B

EP400,0

ECAM interval is 400 counts with zero start

ET[0]=0,0

When master is at 0 position; 1st point.

ET[1]=40,20

2nd point in the ECAM table

ET[2]=120,60

3rd point in the ECAM table

ET[3]=240,120

4th point in the ECAM table

ET[4]=280,140 5

th

point in the ECAM table

ET[5]=280,140 6

th

point in the ECAM table

ET[6]=280,140

7th point in the ECAM table

ET[7]=240,120

8th point in the ECAM table

ET[8]=120,60

9th point in the ECAM table

ET[9]=40,20

10th point in the ECAM table

ET[10]=0,0

Starting point for next cycle

EB 1

Enable ECAM mode

JGC=4000

Set C to jog at 4000

EG 0,0

Engage both A and B when Master = 0

BGC

Begin jog on C axis

#LOOP;JP#LOOP,vl=0

Loop until the variable is set

EQ2000,2000

Disengage A and B when Master = 2000

MF,, 2000

Wait until the Master goes to 2000

ST C

Stop the C axis motion

EB 0

Exit the ECAM mode

EN

End of the program

The above example shows how the ECAM program is structured and how the commands can be given

to the controller. Figure 6.5 provides the results captured by the WSDK program. This shows how the

motion will be seen during the ECAM cycles. The first graph is for the A axis, the second graph

shows the cycle on the B axis and the third graph shows the cycle of the C axis.

DMC-2X00

Chapter 6 Programming Motion

y 99