Cutting fluid, Feed rate – Grizzly G0561 User Manual

Page 28

-26-

g0561 7" x 12" Metal-Cutting Bandsaw

While simple in concept and function, many

issues must be taken into account to find and use

the correct cutting fluid. Always follow all product

warnings and contact the fluid manufacturer for

unanswered questions.

Use the selections below to choose the appro-

priate cutting fluids:

•

For cutting low alloy, low carbon, and gen-

eral-purpose category metals with a bi-metal

blade —use a water soluble cutting fluid.

•

For cutting stainless steels, high carbon, and

high alloy metals, brass, copper and mild

steels—use "neat Cutting oil" (commonly

undiluted mineral oils) that have extreme

pressure additives (ep additives).

•

For cutting cast iron, cutting fluid is not rec-

ommended.

•

For cutting magnesium, use only cutting fluid

that is designed for cutting this material.

remember: too much flow at the cutting fluid

nozzle will make a mess and can make the work

area unsafe; and not enough fluid at the cut will

heat the blade, causing the blade teeth to load up

and break.

Cutting fluid

BIOLOGICAL

AND

pOISON hAzArD! Use

proper personal protection

equipment when handling

cutting fluid and dispose

by following federal, state,

and fluid manufacturer

requirements to properly

dispose of cutting fluid.

the speed at which the saw blade will cut through

a workpiece is controlled by blade type, feed rate,

and feed pressure.

Note: If a lubricant is used on the cut, the feed

rate can be increased by approximately 15%.

To set the feed rate:

1. raise the bow to the maximum height to

remove spring tension. Close the on/oFF

valve to lock the bow in place.

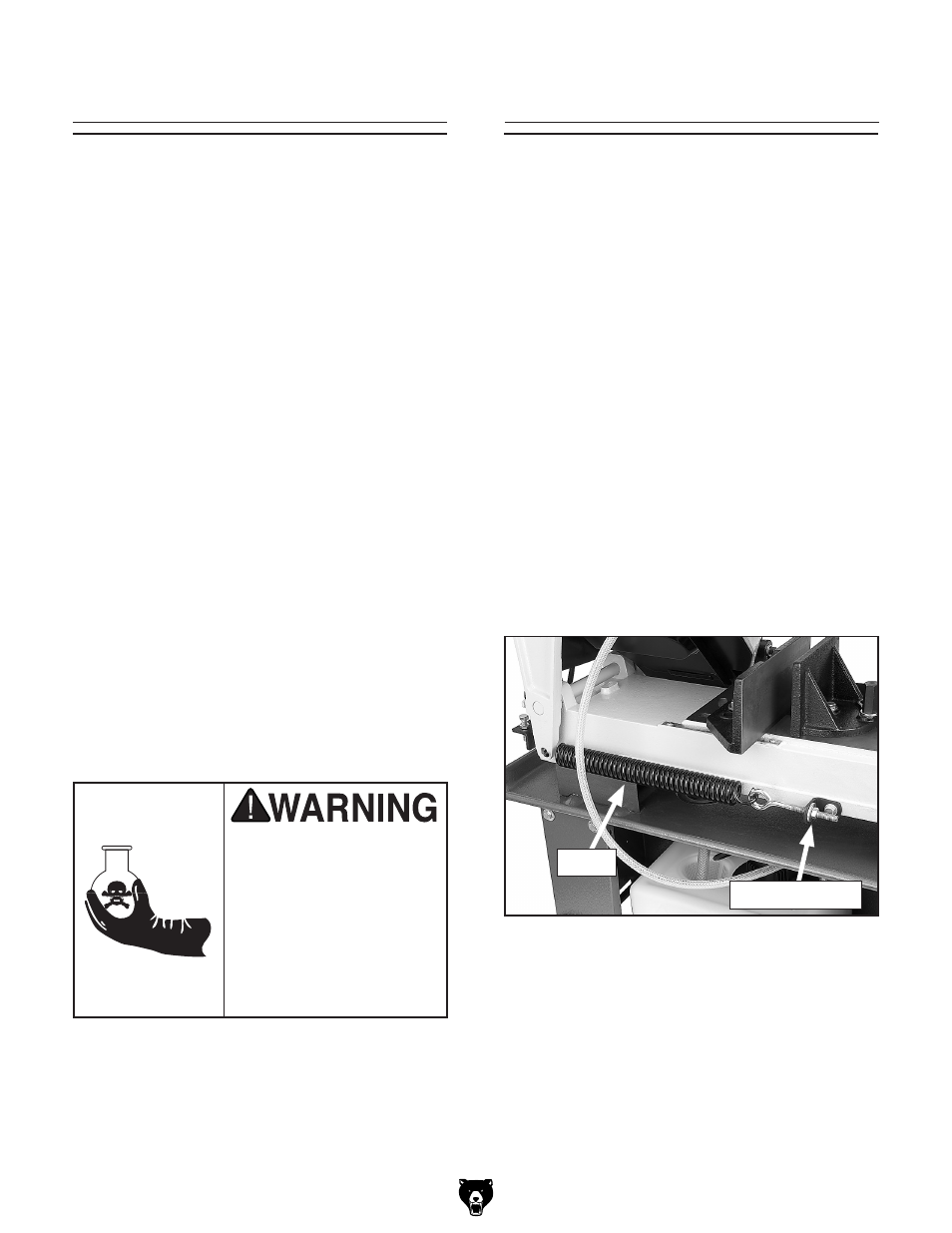

2. using a

9

⁄

16

" wrench, adjust the feed pressure

tension spring. tighten enough to remove

play but not enough to apply tension to the

spring (see

figure 34).

Note: This spring adjustment is an initial set-

ting. Depending on cutting circumstances,

you will have to fine-tune the feed pressure

with this adjustment. Increasing the spring

tension will reduce the feed pressure.

feed rate

3. Clamp the workpiece in the table vise.

4. Close the feed on/oFF valve shown in

figure 35, to lock the bow and blade a few

inches above the workpiece.

figure 34. spring tension adjustment.

spring

Adjustment nut