Choosing blades and speeds – Grizzly G0561 User Manual

Page 25

g0561 7" x 12" Metal-Cutting Bandsaw

-23-

8deeZg

6aadn

''.s)-'

,%&),

'%(s'&(

+'+*

-*"'%(

'++'

''%

+,

''%s*()

+,&+(

'%(

+'

-*

'+

('&

.-

&-%s''%

*)+,

.*s'&(

'.+*

')'

,*

+*s-*

'%'+

&-%s''%

*)+,

,*s&&-

'*(+

')+

,*

&%-s''*

((,*

&.+s(*)

+%&%-

'%(

+'

&&&s('&

().-

&*%s'%(

)++'

6ajb^cjb

6aadn

I]^c

IjWZ

6c\aZ

HiZZa

8VgWdc

HiZZa

HeZZY;EB

B$B^c

HeZZY;EB

B$B^c

HeZZY;EB

B$B^c

HeZZY;EB

B$B^c

BViZg^Va

IDDI=H:A:8I>DC

8JII>C

BViZg^Va

BViZg^Va

BViZg^Va

IddaHiZZa

BdaYHiZZa

=^\]"HeZZY

IddaHiZZa

6aadn

HiZZa

LViZg

=VgYZcZY

IddaHiZZa

HiV^caZhh

HiZZa

8GHiV^caZhh

HiZZa

;gZZBVX]^c^c\

HiV^caZhhHiZZa

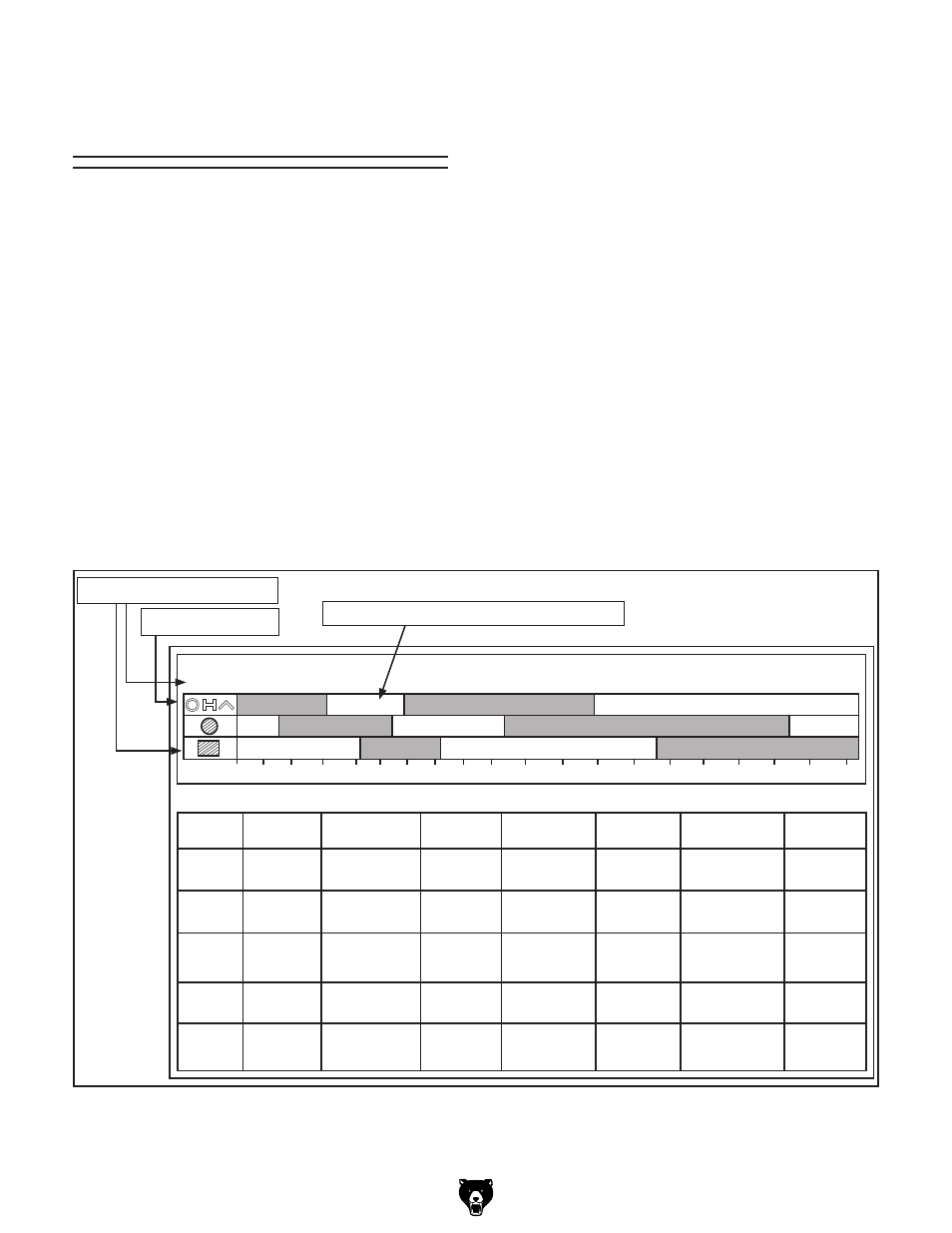

8Vhi>gdc 9jXi^aZ 6jhiZc^i^X 8Vhi>gdc BVaaZVWaZ 8Vhi>gdc EaVhi^Xh 8daY"Ldg` IddaHiZZa =di"Ldg` IddaHiZZa D^a"=VgYZcZY IddaHiZZa *% ' ( ) * + , - . &% && &' &( &) &* &+ &, &- &. ' ( ,* &%% &*% '%% '*% (%% (*% )%% '$( '$( '$( &#)$'#* &#)$'#* &#*$#- &#*$#- ($) ($) ($) )$+ )$+ *$- )*% bb ^cX] Material Width Material shapes teeth per inch variable pitch Blades figure 29. Blade selection and speed chart for metal cutting. selecting the right blade for the job depends on a the chart below is a basic starting point for choos- To select the correct blade TpI: 1. Measure the material thickness. this mea- surement is the length of cut taken from 2. refer to the "Material Width/diameter" row of the blade selection chart in figure 29 and read across to find the workpiece thickness 3. refer to the "Material shapes" row and find the shape and material to be cut. 4. in the applicable row, read across to the right and find the box where the row and column 5. the "Cutting speed rate recommendation" section of the chart offers guidelines for vari- Choosing Blades and Speeds

variety of factors, such as type of material being

cut, hardness of the material, material shape,

machine capability, and operator technique.

ing blade type based on teeth per inch (tpi) for

variable tooth pitch blades and for standard raker

type bi-metal blades/hss blades. however, for

exact specifications of bandsaw blades, contact

the blade manufacturer.

where the tooth enters the workpiece, sweeps

through, and exits the workpiece.

you need to cut.

intersect. listed in the box is the minimum

tpi recommended for the variable tooth pitch

blades.

ous metals, given in feet per minute (speed

FpM) and meters per minute in parenthesis.

Choose the speed closest to the number

shown in the chart.