6 gas inputs (cont.), 7 gas conversion: procedures – Frymaster COOL ZONE SERIES KSCF18G User Manual

Page 22

KSCF18G COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3-9

3.6 Gas Inputs (cont.)

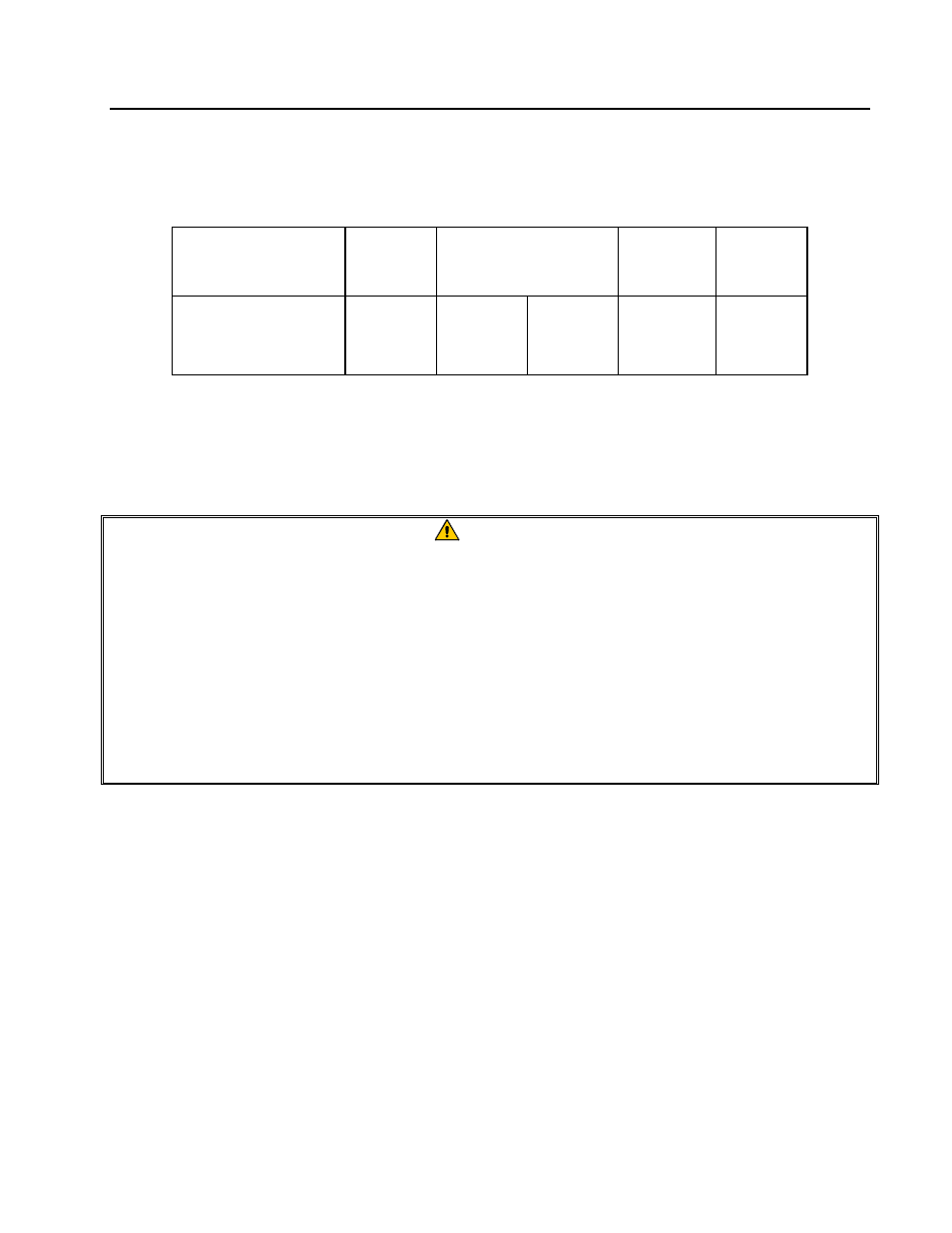

C. Adjustments for different gases are as follows:

ORIFICE SIZE

(# / MM)

GAS TYPE

GAS PRESSURE AT

REGULATOR

BURNER

MARKING

PILOT

MARKING

MBAR INCH

W.C.

#42 / 2,40

#42 / 2,40

#53 / 1,51

G20

G25

G31

10,0

15,0

27,0

4,0

6,0

10,8

Blue

Blue

Red

26N

26N

16LP

NOTE: Outlet gas pressure must be adjusted strictly within the above requirements 5 to 10

minutes after the appliance is operating. For controls and adjustments, please refer to "gas

valve" illustrations on Page 3-10. To adjust the pilot flame, turn the pilot adjustment screw

clockwise/counter-clockwise until the desired flame-volume is achieved.

3.7 Gas Conversion: Procedures

DANGER

This appliance was configured at the factory for a specific type of gas. Converting

from one gas type to another requires the installation of specific gas-conversion

components.

Switching to a different type of gas without installing the proper conversion

components may result in fire or explosion. NEVER ATTACH THIS APPLIANCE TO A

GAS SUPPLY FOR WHICH IT IS NOT CONFIGURED!

Conversion of this appliance from one type of gas to another should only be

performed by qualified, licensed, and authorized installation or service personnel, as

defined in Section 1.7 of this manual.

See Page 3-10 for gas valve illustrations when performing the following conversions.

When converting from G20 to G25 gas, the following procedures apply:

• Equipment replacement is not required.

• Adjust orifice gas pressure by turning the gas valve adjustment screw.

• Seal the screw, after adjustment.

When converting from G20 (or G25) gas to G31 propane (or vice-versa), the following procedures

apply:

• Replace gas valve.

• Replace burner orifices.

• Replace pilot(s).