Engine lubrication – Craftsman 247.88110 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

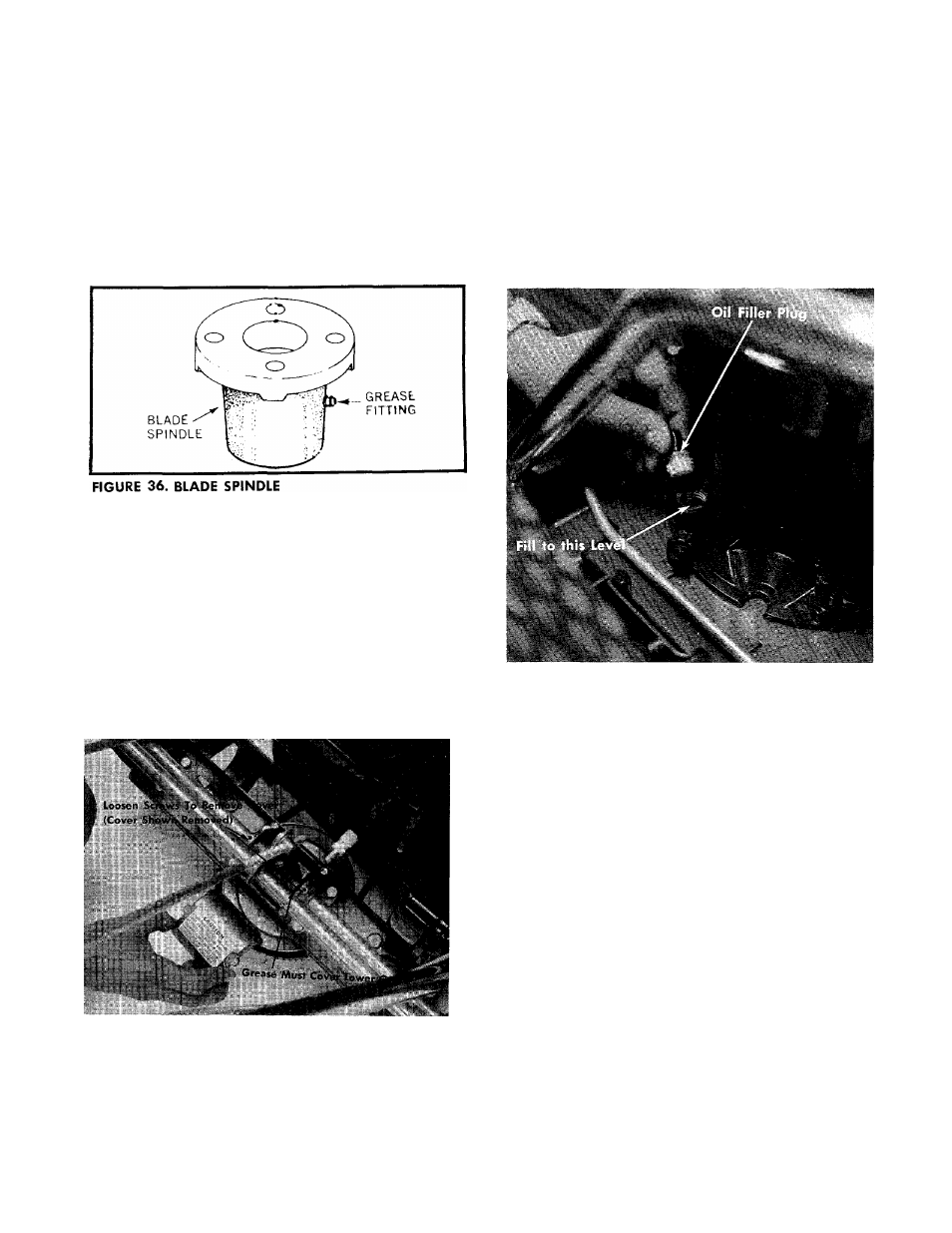

5. Blade Spindle Assembly

The blade spindle assembly, located on the underside

of the mowing deck, is equipped with a grease fitting

Use grass discharge chute for access to the fitting lo

cated under the deck. Use multi-purpose grease. Lubri

cate prior to initial use and every 25 hours thereafter.

See figure 36.

CAUTION

ENGINE LUBRICATION

Be sure spark plug wire is disconnected

and grounded.

6. Gear Box

Check

lubricant

in

the

self-propelled

drive

gear

box.

This

must

be

maintained

half

full

at

all

times

and

should be checked after each 25 hours of operation.

The gear box is packed at the factory with Alduralube

Heavy or Temprite No. 2. It is suggested that this or an

equivalent

type

and

quality

fibrous

high

heat

wheel

bearing grease be used in maintaining this mechanism.

Grease can be ordered by part number 727-111. Hori

zontal

bronze

bearings

under

the

self-propelled

drive

mechanism

should

be

lubricated

with

SAE

30

engine

oil. Refer to figure 37.

CAUTION

Stop the engine and disconnect the

spark plug wire from the spark plug

before making any adjustments.

1. Position equipment so that engine is setting level.

Remove oil filler plug. See figure 38.

FIGURE 38. OIL FILL LOCATION

2.

Pour oil into opening which you removed the oil

filler plug from.

3.

During initial "Break-in" period oil level should

be watched closely.

Oil . . . Use the following:

Summer—Above 32° F—SAE 30 (SAE 10W30 is

an acceptable substitute).

Winter-Below 32°F-SAE 5W20 (SAE 10 or

5W30 are acceptable subsitutes).

Winter-Below 0°F Only—SAE 1OW with 10%

kerosene.

4.

Change oil first two (2) hours of operation and

check oil level every five (5) operating hours or

each time equipment is used.

FIGURE 37. GEAR BOX LUBRICATION

7. Chute Deflector—The torsion spring and pivot point

should be lubricated periodically with oil to prevent

any rust or binding up. Deflector must work freely.

5. Change oil every twenty-five (25) operating hours

or sooner if equipment is operated in extremely

dusty or dirty conditions.

6. Oil can be changed by removing the oil drain plug

located on the right hand side of the engine. See

figure 39.

16