9 safety aspects – Festo Электроцилиндр User Manual

Page 26

2

Overview

26

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

2.9

Safety aspects

Note

Check within the framework of your EMERGENCY STOP procedures to ascertain the

measures that are necessary for switching your machine/system into a safe state in the

event of an EMERGENCY STOP.

•

If an EMERGENCY STOP circuit is necessary for your application, use additional, separate safety

limit switches (e.g. as normally closed limit switches wired in series).

•

Use hardware limit switches or, if required, mechanical safety limit switches and fixed stops or

shock absorbers as appropriate in order to make sure that the axis always lies within the permitted

positioning range.

•

Note the following points:

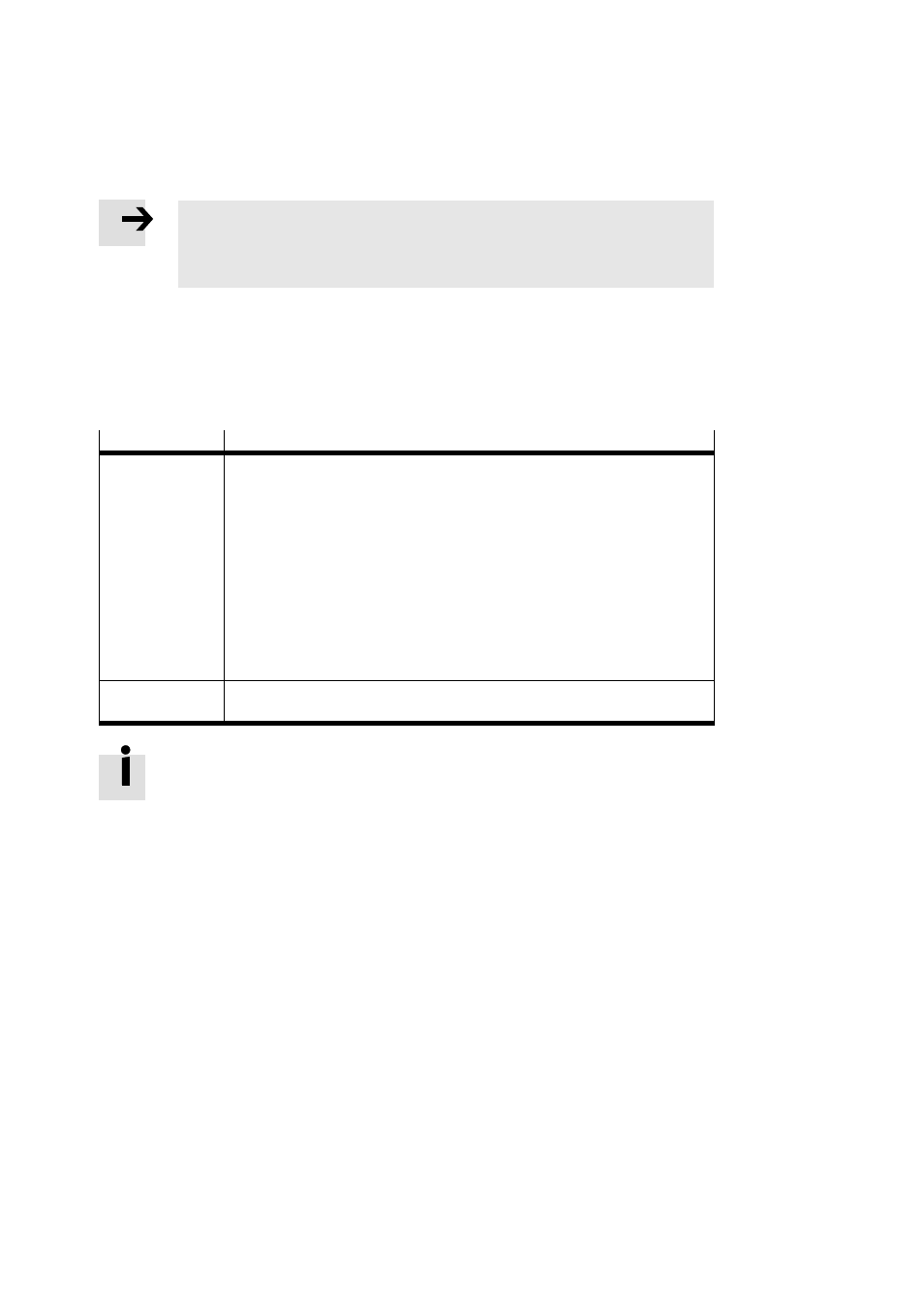

Action

Behaviour

Cancellation of

the ENABLE signal

on the I/O

interface

–

Without brake/clamping unit:

The drive brakes with the quick stop ramp (Quick stop). The controller

output stage is then switched off. The effective load could possibly slide

down if mounted in a vertical/inclined position.

–

When using a brake/clamping unit:

If the drive moves when ENABLE is cancelled, then it will initially be brought

to rest using Quick Stop deceleration. As soon as the drive has come to a

standstill, the brake output is reset: the brake/clamping unit closes.

Simultaneously, the switch-off delay time begins to run. The CMMO-ST still

controls the position. The controller end stage is switched off after the

switch-off delay.

Switching off the

load voltage

The load voltage is switched off. The effective load on the drive may continue to

move due to inertia, or it will fall if mounted in a vertical or sloping position.

For STO function:

separate document GDCP-CMMO-ST-STO-…