Festo Неполноповоротный привод DFPB User Manual

Page 6

Setting the inner end position of the single−acting DFPB

1. Using an Allen key, turn the adjusting screw

aJ:

ć clockwise to expand the angle of rotation

ć counter−clockwise to reduce the angle of rotation

until the connected process valve reaches the desired position.

· To reduce the angle of rotation, carefully pressurise the DFPB as necessary

with compressed air at port 2 (A).

· Vent the DFPB again immediately following.

2. Turn the opposite adjusting screw

aJ in the same direction until you feel

resistance. Make sure that this does not change the position of the connected

process valve.

Completing the setting of the end positions:

1. Tighten the locking nuts

7 back on the adjusting screws aJ.

2. Pressurise

ć the double−acting DFPB in alternation at ports 2 (A) and 4 (B)

ć the single−acting DFPB only at port 2 (A).

· Check whether the connected process valve reaches the desired positions.

8

Care and maintenance

If used as designated in the operating instructions, the device will be free of

maintenance.

9

Dismantling and repairs

Warning

Danger of injury from uncontrolled motions.

· Switch the tubing system pressureless before dismantling.

Warning

In the single−acting DFPB, the spring mounts are connected in each case to the

housing covers including the built−in springs

only via the adjusting screws.

When dismantling the housing covers, the spring returns in the device can cause

the covers to fly off and cause injury if the covers are not securely connected to

the spring mounts by the adjusting screws. There is danger of this if the

connecting adjusting screws do not behave as described in these instructions. To

prevent the housing cover from flying off, you must ensure

· that the adjusting screws of the DFPB

never get screwed all the way into the

device.

· that the spring pre−tension force is taken up by the adjusting screw when

loosening the tie rod nuts. For this, the tie rod nuts must be easy to turn. Be

careful if they are not easy to turn. Also be careful if the adjusting screw is

easy to turn in the pressureless state.

In all these cases, the drive must not be opened.

Note

When the connection screws are loosened, the DFPB may switch in an uncontrolĆ

led manner.

· Vent the DFPB before starting any dismantling work.

1. If necessary, remove any existing limit switches.

2. Remove the solenoid valve.

3. Loosen the screws on the flange of the process valve.

4.Remove the semi−rotary drive from the process valve.

5. Send the device to Festo for repairs.

10

Accessories

Please select the appropriate accessories from our catalogue

è

www.festo.com/catalogue

11

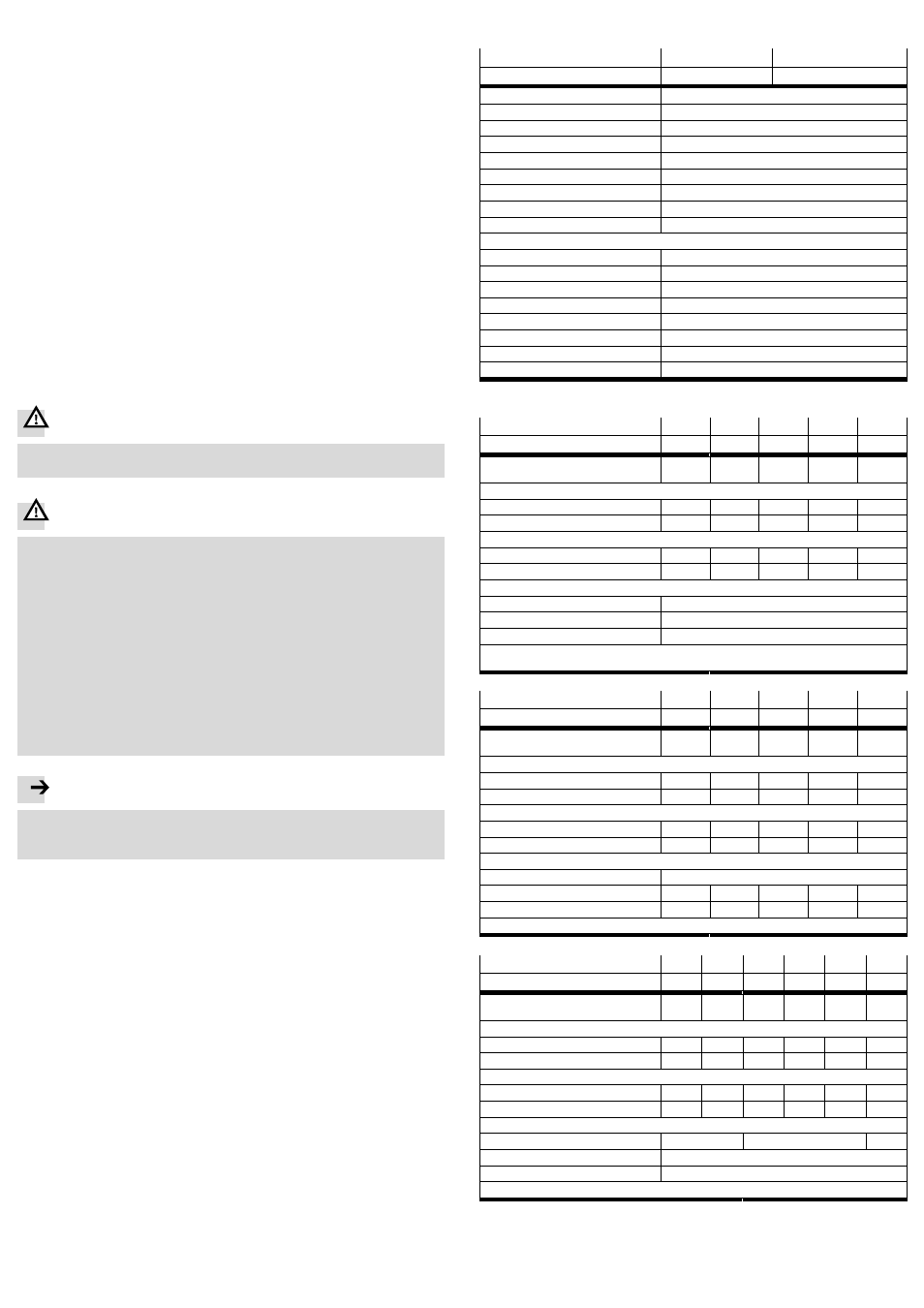

Technical data

DFPB, double−acting

10 ... 300

370 ... 1050

DFPB, single−acting

10 S ... 150 S

180 S ... 520 S

Pneumatic connection

G1/8

Design

Rack and pinion, double−acting

Assembly position

as desired

Swivel angle

[°]

90

End position adjustment range

[°]

±4

Closing direction

as desired

Operating pressure

[bar]

1

Ū 8

Operating medium

Dried compressed air, lubricated or unlubricated

Ambient temperature

[°C]

ć20

Ū +80

Materials

Cover

Die−cast aluminium, painted

Housing

Anodised aluminium

Shaft

Anodised aluminium

Piston

Die−cast aluminium

External screws

Stainless steel

Locking nuts

Anodised aluminium

Springs

Steel

Seals

Nitrile rubber

Fig. 7

DFPB, double−acting

10

20

30

45

65

DFPB, single−acting

ć

10 S

15 S

20 S

30 S

Flange hole pattern

(see type designation)

ISO5211

F03

F04

F03

2)

F04

F05

F04

2)

F05

Product weight

ć double−acting

[kg]

0,5

1

1,3

1,7

2,2

ć single−acting

[kg]

ć

1,7

2,5

3,1

4,4

Air consumption at an operating pressure of 6 bar per cycle

ć double−acting

[l]

0,18

0,45

0,62

0,89

1,33

ć single−acting

[l]

ć

0,23

0,31

0,44

0,66

Switching times

1)

ć double−acting

[s]

< 1

ć single−acting, air

[s]

< 1

ć single−acting, spring

[s]

< 1

1) The switching times correspond to average values under idling conditions.

2) For single−acting DFPB only (S)

DFPB, double−acting

80

120

170

230

300

DFPB, single−acting

40 S

60 S

80 S

110 S

150 S

Flange hole pattern

(see type designation)

ISO5211

F05

F0507

F0710

F0710

F0710

Product weight

ć double−acting

[kg]

2,6

4,2

5,2

7,1

7,8

ć single−acting

[kg]

5,2

8,8

10,7

16,7

18,8

Air consumption at an operating pressure of 6 bar per cycle

ć double−acting

[l]

1,66

2,42

3,5

4,72

6,07

ć single−acting

[l]

0,83

1,21

1,75

2,36

3,04

Switching times

1)

ć double−acting

[s]

< 1

ć single−acting, air

[s]

< 1

< 1

< 1

< 1,5

< 2

ć single−acting, spring

[s]

< 1

< 1

< 1,5

< 2

< 2

1) The switching times correspond to average values under idling conditions.

DFPB, double−acting

370

470

550

670

840

1050

DFPB, single−acting

180 S 230 S 270 S 330 S 420 S 520 S

Flange hole pattern

(see type designation)

ISO5211

F1012

F1012

F1012

F1012

F14

F14

Product weight

ć double−acting

[kg]

12,9

14,2

18,6

20,4

30,5

32,2

ć single−acting

[kg]

34,2

28,7

50,5

49,8

76,1

92,2

Air consumption at an operating pressure of 6 bar per cycle

ć double−acting

[l]

7,45

9,31

10,9

13,4

16,6

20,7

ć single−acting

[l]

3,72

4,65

5,47

6,69

8,29

10,4

Switching times

1)

ć double−acting

[s]

< 1,2

< 1,6

< 2

ć single−acting, air

[s]

< 2

ć single−acting, spring

[s]

< 2

1) The switching times correspond to average values under idling conditions.

Fig. 8