Lubrication – Hawk Industries Spinner Manual 550 HYDRAULIC Serial Numbers 1 to 205 User Manual

Page 20

20

Maintenance & Repair

1. Make sure the Spinmaster is off

the drill pipe connection and in

the rest position on the derrick.

2. Shut down the power unit.

3. Bleed any hydraulic and/or air

pressure from the Spinmaster,

by cycling the door valve lever.

4. Assume that there is still a load

on every actuator. Proceed with

caution.

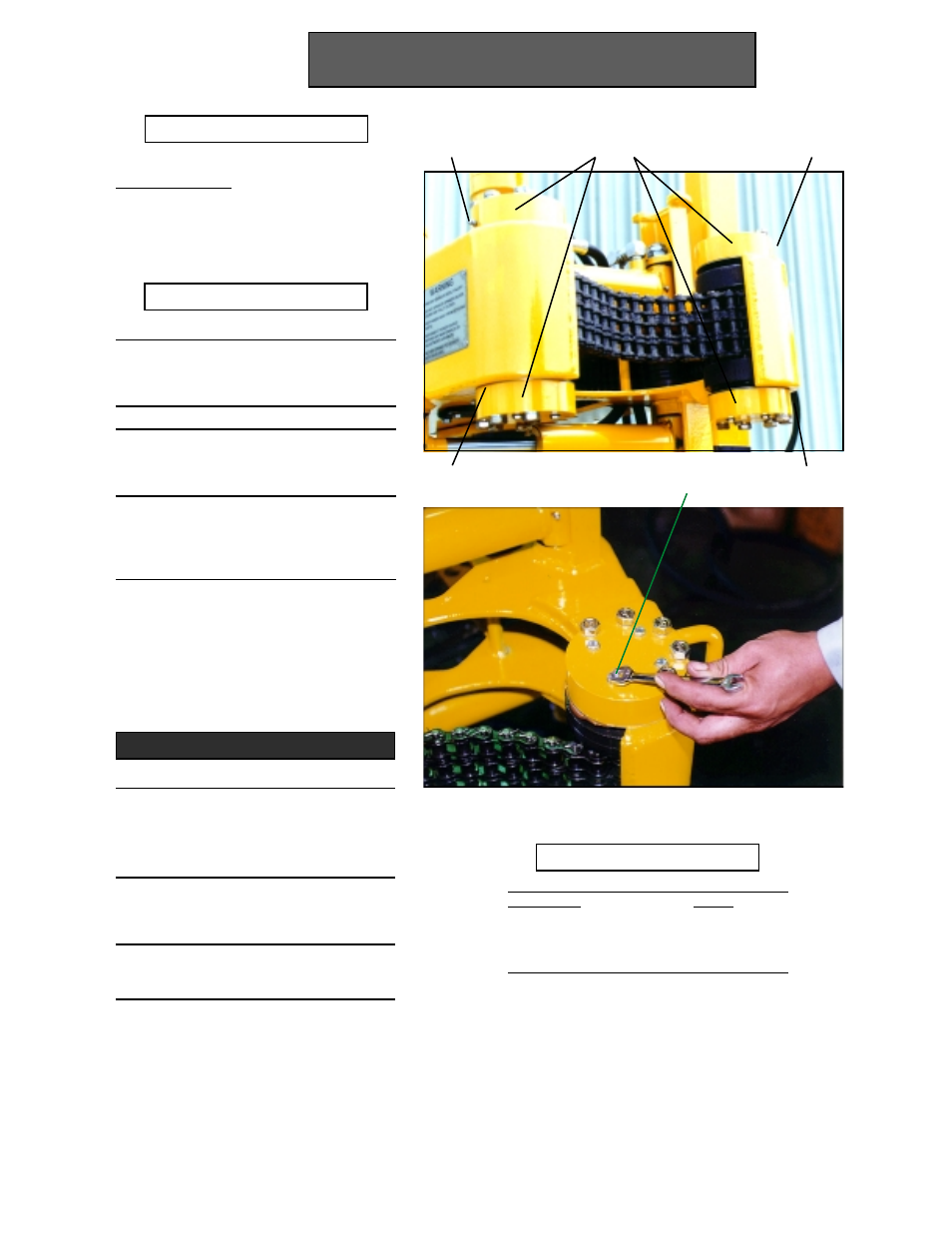

Grease Once per Month

Initial Steps

BC

Part Name

Part #

Bearing Cap Screw (S)

999-805834

Straight Grease Fitting 061-1103K1

Part Numbers

Tools Required

Drive Roller Sprocket Bearings

1. Use the 7/16" wrench to remove

one of the four small screws (S)

from the top of each bearing

cap (BC).

2. Pump the four grease fittings

G1-G4 until grease comes out of

the small screw hole.

3. Use the 7/16" wrench to replace

the small screw (S).

G1

G2

G4

G3

Lubrication

S

Grease gun, 7/16" wrench