0 operating instructions – Ingersoll-Rand NIRVANA IRN75-160K-2S User Manual

Page 67

IRN37 - 160K - CC & IRN50 - 200H & IRN75 - 160K - 2S & IRN - 100 - 200H - 2S & IRN 250 - 300H - 2S

http://air.irco.com

65

9.0 OPERATING INSTRUCTIONS

9.1 BASIC OPERATION

WARNING

Ensure that all protective covers/guards are in place before

attempting to start the machine.

WARNING

The compressor can operate in a pressurized shutdown

mode. If the compressor stops automatically, the airend,

separator tank and oil system can contain high pressure air.

This can be relieved by pressing the emergency stop button

and can be verified by unscrewing the coolant fill plug which

has a vent hole through which any residual pressure will be

vented. Downstream of the separator tank may still contain

system pressure which must also be vented.

NOTICE

The language and units of measure displayed on the Intellisys

controller will be pre−set before leaving the factory. If these

are required to be changed, contact your local Ingersoll Rand

Service Department, Distributor or Air Center.

Prior to starting

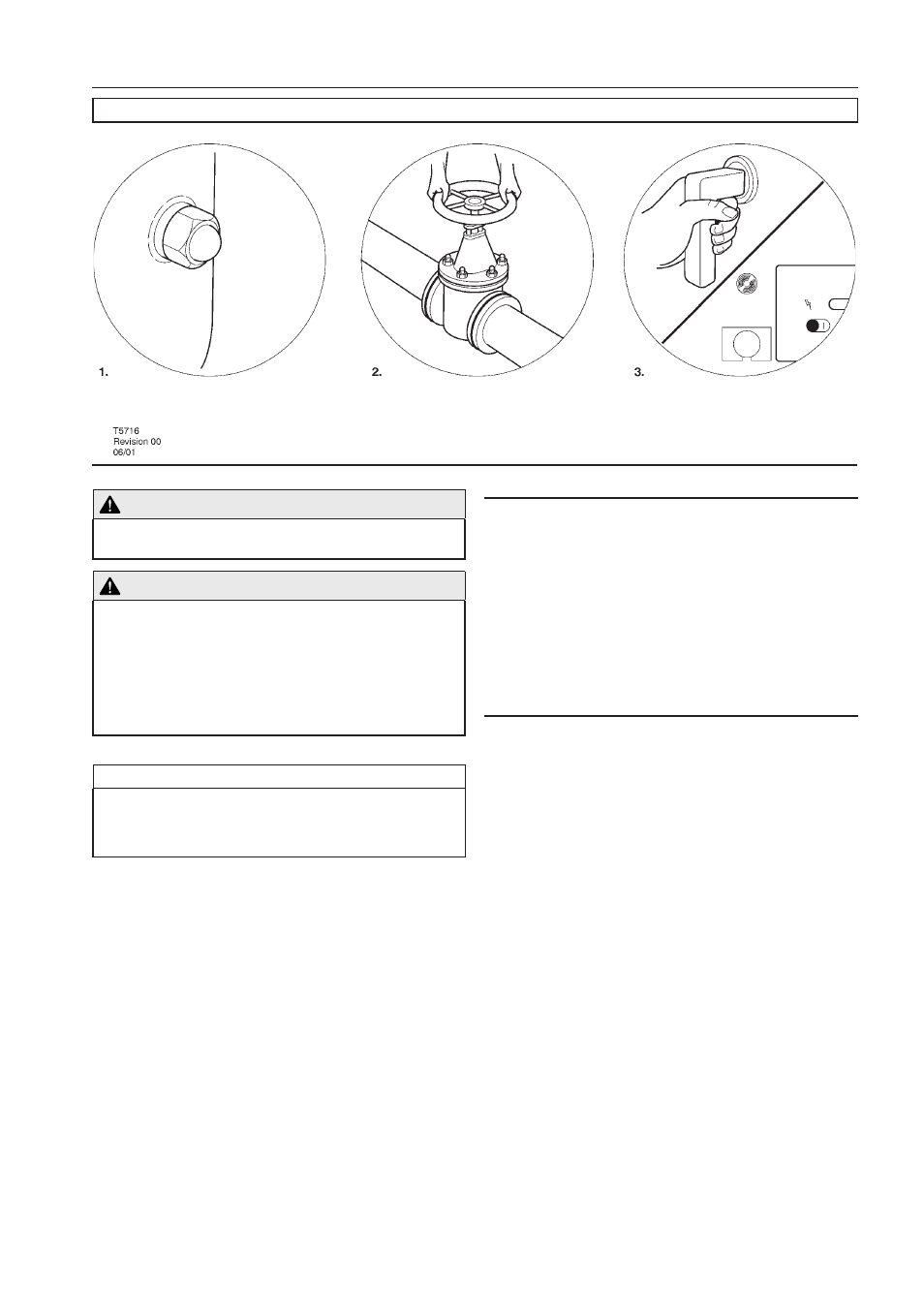

Refer to diagram T5716 above.

Check that the coolant level is at least visible in the center of

the sight glass, add coolant if necessary. Refer to maintenance

procedures for setting correct level.

Ensure that the discharge air isolation valve is open. Switch on the

main electrical isolation switch. The control panel will illuminate,

indicating that the line and control voltages are available.

The contrast of the display may be adjusted by turning the small

screw which is on the right hand side of the controller when

accessed through the starter cabinet door.

Initial check sequence

The controller will perform an initial check sequence if the

compressor (1) receives initial power to the controller or (2) has

experienced an alarm reset. While the initial check sequence occurs,

the controller will display a “Checking Machine” message.

During the initial check sequence, the controller will check the

control system for proper operation. During this time, if any items

are found inoperative an alarm will occur and the unit will not start.

After completion of the initial check sequence, the controller will

then display “READY TO START’. This process should be completed

within 10 seconds.