Installation instructions, Site requirements, Flue and chimney requirements – Stovax STUDIO 8700CFCHEC User Manual

Page 11: Flue options, Gas supply, Ventilation, Appliance location

11

INSTALLATION INSTRUCTIONS

SITE REQUIREMENTS

1. FLUE AND CHIMNEY REQUIREMENTS

WHEN INSTALLING A FLUE SYSTEM PLEASE REFER TO

THE MANUFACTURER’S INSTRUCTIONS.

The European chimney standards now describe chimneys

and flues by their temperature, pressure and resistance to

corrosion, condensation and fire. To identify the correct flue

system, the minimum flue specification is shown in the

Technical Specification. Existing chimneys are not covered

by this system.

The flue must be installed in accordance with all local and

national regulations and the current rules in force:

• A flexible liner must be continuous from the appliance

spigot to the roof terminal

• The minimum effective height of the flue must be 3

metres (10ft)

• The flue must be free from any obstruction

• Any damper plates must be removed or secured in the

fully open position and no restrictor plates fitted

• The chimney should be swept immediately before

installing the appliance, but it need not be swept if you can

see the chimney is clean and free from obstruction

throughout

2. FLUE OPTIONS

There are three suitable Conventional Flues:

• Stud work is Top Exit only - Twin Wall Rigid

127mm (5”)

• Top Exit - Builder’s Opening Lined

127mm (5”)

• Rear Exit - Builder’s Opening Unlined

178m (7”) minimum

3. GAS SUPPLY

THIS APPLIANCE IS INTENDED FOR USE ON A GAS

INSTALLATION WITH A GOVERNED METER.

3.1 Make sure local distribution conditions (identification of the

type of gas and pressure) and the adjustment of the

appliance are compatible before installation.

3.2 Ensure the gas supply delivers the required amount of gas

and is in accordance with the rules in force.

3.3 You can use soft copper tubing on the installation and soft

soldered joints outside the appliance and below the fire.

3.4 A factory fitted isolation device is part of the inlet

connection; no further isolation device is required.

3.5 All supply gas pipes must be purged of any debris that may

have entered prior to connection to the appliance.

3.6 The gas supply enters through the silicone panel located on

the LEFT-HAND side of the outer box:

• Slit with a sharp knife prior to passing the supply pipe

through

3.7 The gas supply must be installed in a way that does not

restrict the removal of the appliance for servicing and

inspection.

4. VENTILATION

IMPORTANT: Ensure any national ventilation

requirements are taken into account during installation

of the fire.

Uk ONLY:

The Studio 1 has a nominal input not exceeding 7.0kW and

does not normally require any additional permanent

ventilation.

The Studio 2 must have permanent ventilation with a

minimum open area of 5.85cm

2.

FOR THE REPUBLIC OF IRELAND REFER TO THE RULES

IN FORCE FOR VENTILATION REQUIREMENTS

5. APPLIANCE LOCATION

NOTE: It is recommended you construct the back panel

of the fireplace from natural materials cut into three or

more sections to prevent cracking. Resin-based materials

may not be suitable. This appliance is an effective heat

producer and attention must be paid to the construction

and finish of the fireplace.

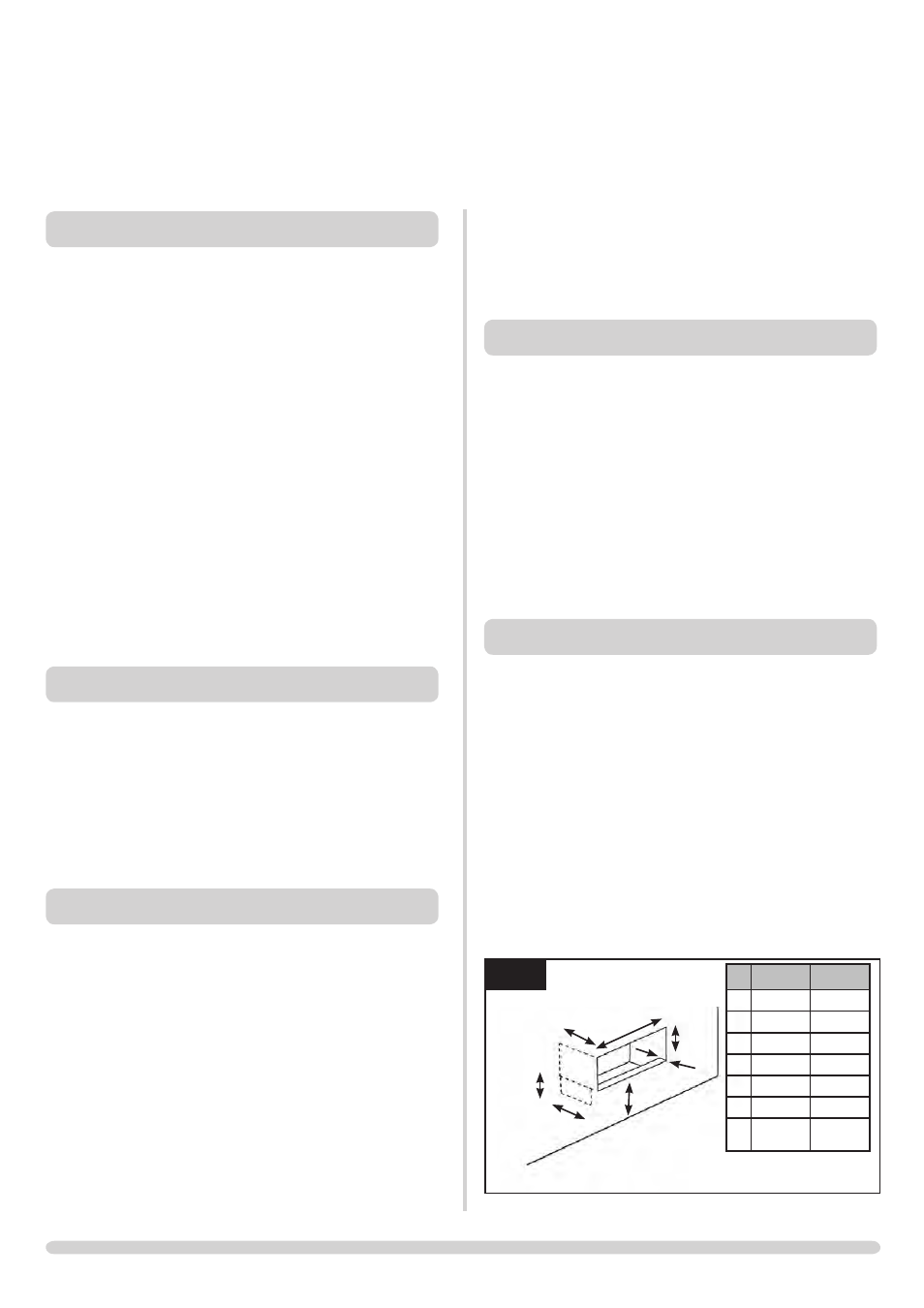

When preparing the aperture for installation into a builder’s

opening, the front of the wall must be cut out down to the

level on which the appliance is to stand. Then, to obtain the

correct dimensions shown in Diagram 1a, the lower section

of wall must be reconstructed as shown in Diagram 1a

5.1 This appliance must stand on a non-combustible base that is

at least 12mm thick; the minimum opening dimensions are

shown in Diagram 1a.

AR1906

1a

C

D

A

E

G

F

B

Studio 1

Studio 2

A

760mm

960mm

B

440mm

440mm

C

350mm

350mm

D

85mm

85mm

E

305mm

305mm

F

45mm max

45mm max

G

175mm

min

175mm

min