Factory-built zero clearance fireplace, Warning – Hearth and Home Technologies 4100I-GD-B User Manual

Page 11

Page 11

September 1, 2008

4100-I ACT WOOD INSERT

250-7201E

R

FACTORY-BUILT ZERO CLEARANCE FIREpLACE

(USA iNSTAllATiONS ONlY)

Listed Liner

Mantel

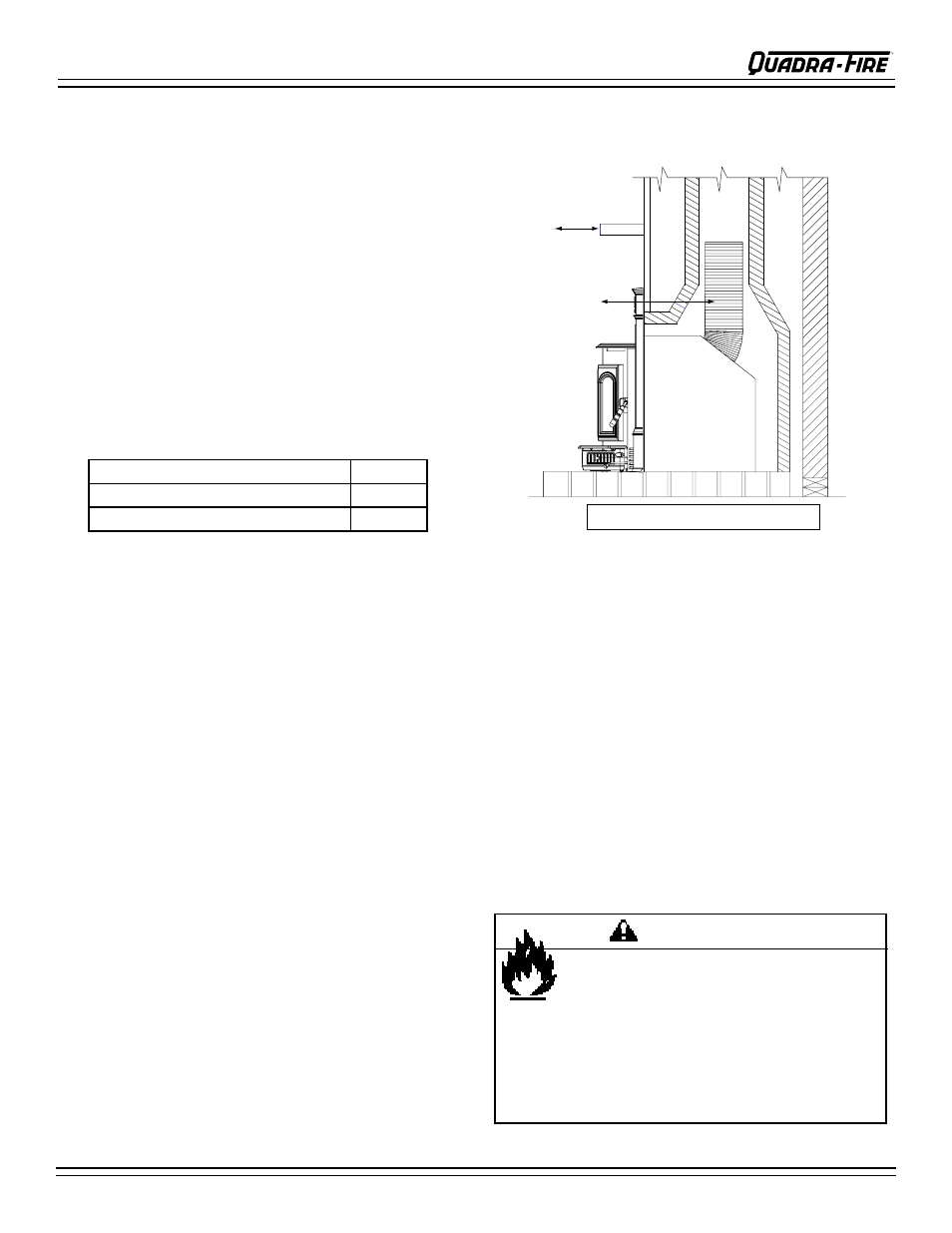

SEAL DAMpER AREA OR FACE SEAL

Figure 11A - installation into A Factory Built

Zero Clearance Fireplace

The following modifications of factory built fireplaces are

permissible: 1) removal of damper; 2) removal of smoke

shelf or baffle; ) removal of ember catches; 4) removal

of fire grate; 5) removal of viewing screen/curtain; and, 6)

removal of doors.

NOTE: installation into fireplaces without a permit

will void the listing.

The factory built chimney must be listed per UL 127 and

meet the type HT requirements of UL 10. Factory built

fireplace chimneys tested to UL 127-1998, may be at the

fireplace manufacturer’s option, tested to the same criteria

as UL 10 HT requirements. If the chimney is not listed

as meeting HT requirements, or if the factory built fire-

place was tested prior to 1998, a full height listed chimney

liner must be installed from the appliance flue collar to the

chimney top. The liner must meet type HT requirements

(2100ºF) per UL 1777.

The liner must be securely attached to the insert flue collar

and the chimney top. To prevent room air passage to the

chimney cavity of the fireplace, seal either the damper area

around the chimney liner with high temperature sealant or

the fireplace front with fiberglass batting.

The fireplace must not be altered, except that the damper

may be removed to accommodate a direct-connect starter

pipe or chimney liner, and external trim pieces which do

not affect the operation of the fireplace may be removed

providing they can be stored on or within the fireplace for

reassembly if the insert is removed.

The Quadra-Fire 4100-I ACT Wood Stove Insert is listed to

UL 1482 Standard and approved for installation into listed

factory built zero clearance fireplaces listed to UL 127 con-

forming to the following specifications and instructions:

Minimum Width of cavity opening:

0 in.

Minimum Height:

21 in.

Minimum Depth from front to rear:

16-1/4 in.

The original factory-built clearance fireplace chimney cap

must be re-installed after installing the approved chim-

ney liner meeting type H.T. requirements (2100°F) per UL

1777. The air flow of the factory-built zero-clearance fire-

place system must not be altered. The flue liner top support

attachment must not reduce the air flow for the existing air-

cooled chimney system.

NOTE: Refer to chimney liner manufacturer for rec-

ommendations on supporting the liner.

The permanent metal warning label provided must be

attached to the back of the fireplace, with screws or nails,

stating that the fireplace may have been altered to accom-

modate the insert, and must be returned to original condition

for use as a conventional fireplace.

If the hearth extension is lower than the fireplace opening,

the portion of the insert extending onto the hearth must be

supported. Manufacturer designed adjustable support kit

can be ordered from your dealer.

(See page 14).

Final approval of this installation type is contingent upon

the authority having jurisdiction.

Fire Risk.

When lining air-cooled factory-built chimneys:.

• Run chimney liner approved to UL 1777 Type

HT requirements (2100 degrees F)

• Re-install original factory built chimney cap

ONLY

• DO NOT block cooling air openings in chimney

• Blocking cooling air will overheat the chimney

WARNING