Installation options, Metal heat circulating masonry – Hearth and Home Technologies 4100I-GD-B User Manual

Page 10

4100-I ACT WOOD INSERT

Page 10

September 1, 2008

R

250-7201E

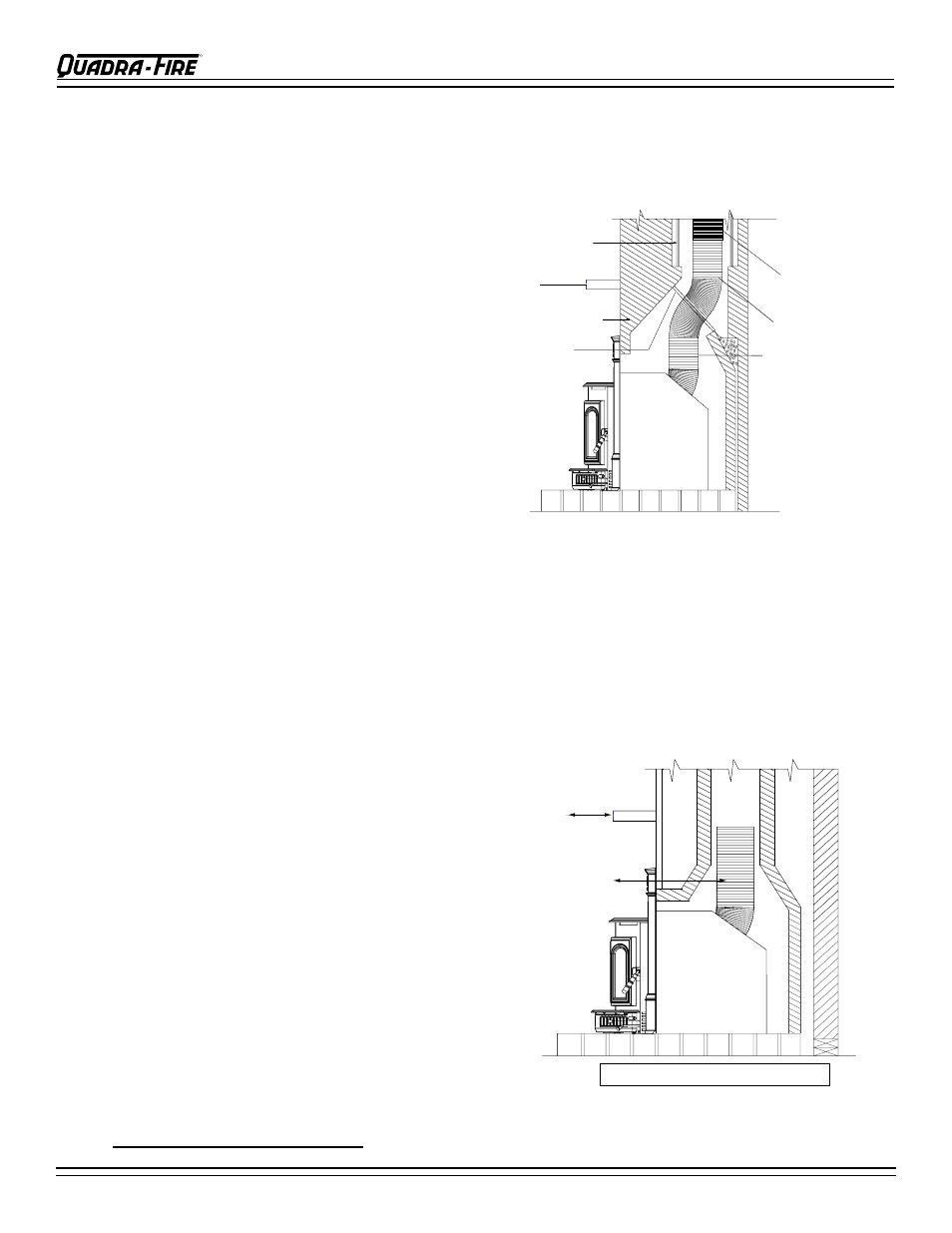

MASONRY FIREpLACE

USING DIRECT-CONNECT METHOD

Refer to: Clearances to Combustibles on page 5, Canadian installation requirements on page 12,

Hearth Requirements on page 5 and Zero Clearance Adjustable Support Kit on page 16.

Figure 10A - installation into Masonry Fireplace

Direct Connect

Seal Option

Minimum Starter

Pipe Option

Full Listed

Liner Option

Masonry Chimney

Flue Tile

Mantel

Air-tight Face Seal

Damper Area

SEAL DAMpER AREA OR FACE SEAL

INSTALLATION OpTIONS

This product conforms with the UL Standard for Safety

1482 (USA) and ULC S628 (Canada) in all respects, and

is approved to UL & ULC safety standards for installation

and use within a fireplace with a masonry chimney in accor-

dance with NFPA 211, with or without a direct flue collar con-

nection. A starter pipe is required to reach to the bottom of

the existing flue.

1. Secure the fireplace damper in the open position. If this

cannot be accomplished, it will be necessary to remove

the damper.

2. Seal either the damper area around the chimney liner

with a high temperature sealant or the fireplace front with

fiberglass batting.

. The chimney should be examined for cracks, loose

mortar, and other signs of deterioration and blockage.

The insert should not be installed until it is determined

that the chimney is safe for use. Since an oversized flue

contributes to the accumulation of creosote, the size of

the flue should be checked to determine that it is not too

large for the insert. The chimney should also be checked

to ensure it meets the minimum standard of the National

Fire Protection Association (NFPA) Standard 211. The

following bullets list the more critical requirements for a

properly constructed chimney:

• The masonry wall of the chimney, if brick or modular

block, must be a minimum of 4 inches (102mm) nominal

thickness. A chimney of rubble stone must be at least 12

inches (05mm) thick

• The chimney must have a fire clay flue liner (or equiva-

lent) with a minimum thickness of 5/8” (16mm) and must

be installed with refractory mortar. An equivalent liner

must be a listed chimney liner system or other approved

material.

• Cross-sectional area should be no more than times the

cross-sectional area of the flue collar of the insert. (28 sq

inch flue area x inches = 84 square inches maximum

chimney area).

• A chimney inside the house must have at least two inches

(51mm) of clearance to the combustible structure. A chim-

ney outside the house must have at least 1 inch (25mm)

clearance to the combustible structure. Non-combustible

fire stops must be installed at the spaces where the chim-

ney passes through floors and/or ceiling

(See Figure 8A

and 8B on page 8).

NOTE: In Canada, a full reline is required.

METAL HEAT CIRCULATING MASONRY

This product conforms with the safety standard UL1482

(USA) and ULC S628 (Canada) in all respects and is

approved to UL & ULC safety standards for installation and

use within a fireplace with masonry chimney, in accordance

with NFPA 211, with or without a direct flue collar connec-

tion. A starter pipe is required into existing chimney.

Figure 10B

-

installation into Metal Heat Circulating

Showing Use Of Starter Pipe

Listed Liner

Mantel

SEAL DAMpER AREA OR FACE SEAL