Gun operation troubleshooting – HP GRACO OR PRO TI1681A User Manual

Page 38

Troubleshooting

38

309293J

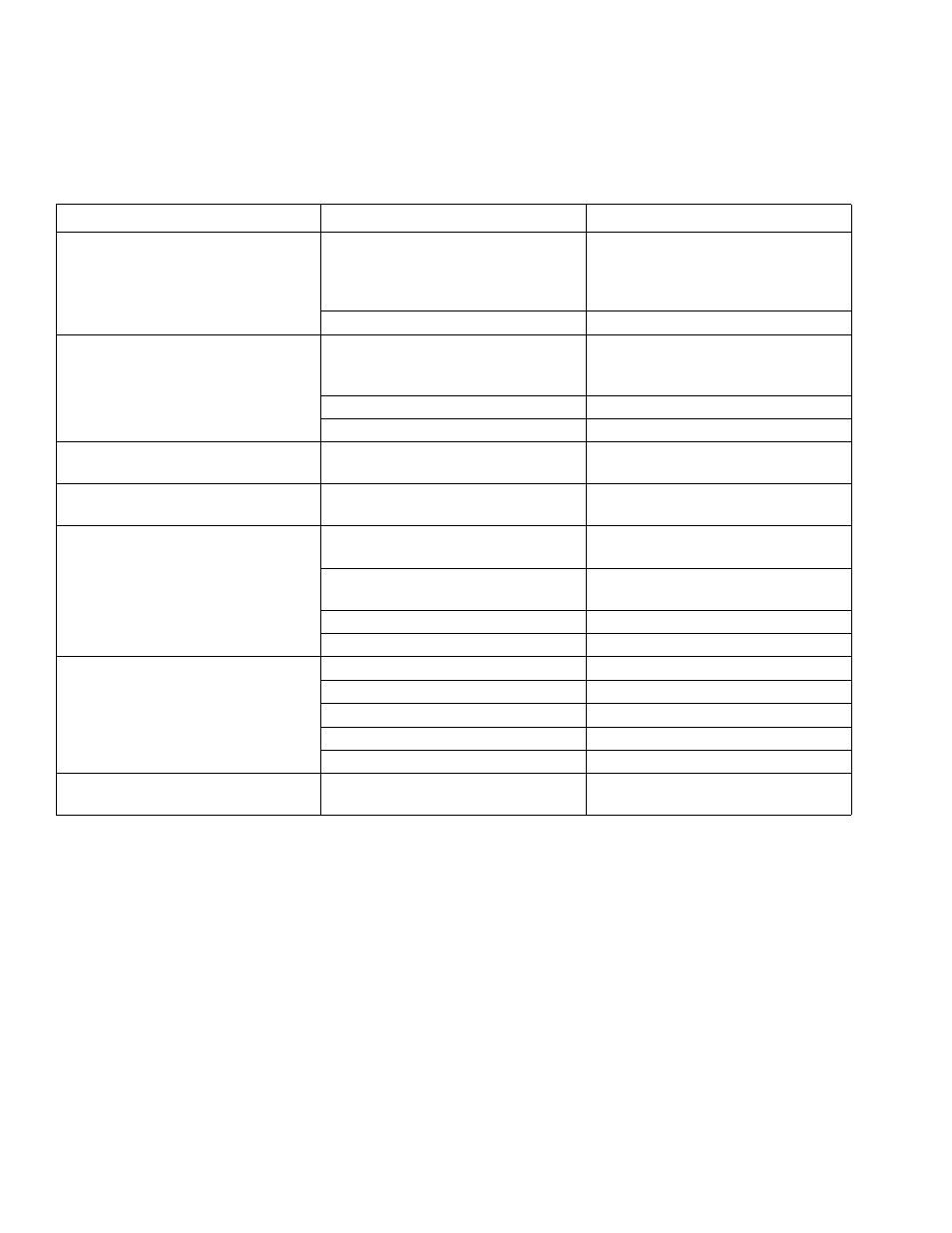

Gun Operation Troubleshooting

Problem

Cause

Solution

Excessive spray fog.

Atomizing air pressure too high.

Close restrictor valve some, or

decrease air pressure as low as pos-

sible; minimum 40 psi (0.28 MPa, 2.8

bar) needed at gun for full voltage.

Fluid too thin.

Increase viscosity.

“Orange Peel” finish.

Atomizing air pressure too low.

Open atomizing air valve more or

increase gun air inlet pressure; use

lowest air pressure necessary.

Poorly mixed or filtered fluid.

Remix or refilter fluid.

Fluid too thick.

Reduce viscosity.

Fluid leaks from the fluid packing

area

Worn packings or rod.

Replace packings or rod; see page

45.

Air leaks from the front of the gun

Air valve (21) is not seating properly.

Clean and service air valve; see

page 50.

Fluid leakage from the front of the

gun

Worn or damaged packing rod (26).

Replace; see page 45

Worn fluid seat.

Replace fluid nozzle and/or electrode

needle; see pages 42 to 43.

Loose fluid nozzle (7).

Tighten; see page 42.

Damaged nozzle o-ring (7b).

Replace; see page 42.

Gun does not spray

Low fluid supply.

Add fluid if necessary.

Damaged air cap (9).

Replace; see page 42.

Dirty or clogged fluid nozzle (7).

Clean; see page 42.

Damaged fluid nozzle (7).

Replace; see page 42.

Damaged fluid adjustment valve (25). Replace; see page 50.

Dirty air cap

Misaligned air cap (9) and fluid noz-

zle (7).

Clean fluid buildup off air cap and

fluid nozzle seat; see page 29.