Maintenance and inspection, Monthly and yearly inspection chart, Maintenance and inspection 6–10 – Hitachi L300P User Manual

Page 212

Maintenance and Inspection

T

roub

leshooting

and Maintenance

6–10

Maintenance and Inspection

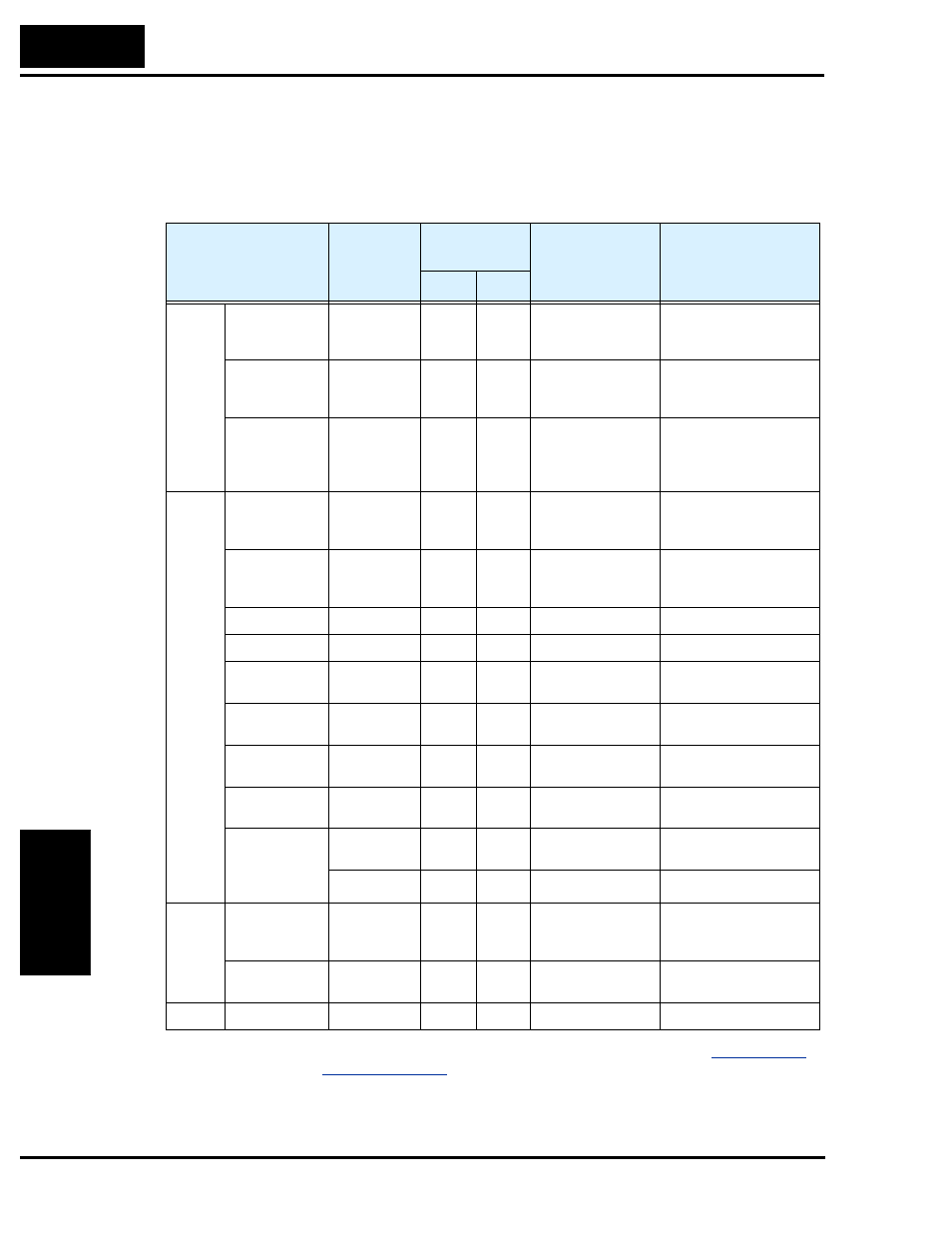

Monthly and

Yearly Inspection

Chart

Note 1: The life of a capacitor is affected by the ambient temperature. See

.

Note 2: The inverter must be cleaned periodically. If dust accumulates on the fan and heat

sink, it can cause overheating of the inverter.

Item Inspected

Check for...

Inspection

Cycle

Inspection Method

Criteria

Month

Year

Overall

Ambient

environment

Extreme

temperatures

& humidity

✔

Thermometer,

hygrometer

Ambient temperature

between -10 to 50°C,

non-condensing

Major devices

Abnormal

vibration,

noise

✔

Visual and aural

Stable environment for

electronic controls

Power supply

voltage

Voltage toler-

ance

✔

Digital volt meter,

measure between

inverter terminals

[L1], [L2], [L3]

200V class:

200 to 240V 50/60 Hz

400V class:

380 to 460V 50/60 Hz

Main

circuit

Ground

Insulation

Adequate

resistance

✔

Megger test

500VDC, reading of 5M

ohms or greater, see next

section for test details

Mounting

No loose

screws

✔

Torque wrench

M3: 0.5 – 0.6 Nm

M4: 0.98 – 1.3 Nm

M5: 1.5 – 2.0 Nm

Components

Overheating

✔

Thermal trip events

No trip events

Housing

Dirt, dust

✔

Visual

Vacuum dust and dirt

Terminal block

Secure

connections

✔

Visual

No abnormalities

Smoothing

capacitor

Leaking,

swelling

✔

Visual

No abnormalities

Relay(s)

Chattering

✔

Aural

Single click when

switching ON or OFF

Resistors

Cracks or

discoloring

✔

Visual

Use Ohm meter to check

braking resistors

Cooling fan

Noise

✔

Power down,

manually rotate

Rotation must be smooth

Dust

✔

Visual

Vacuum to clean

Control

circuit

Overall

No odor,

discoloring,

corrosion

✔

Visual

No abnormalities

Capacitor

No leaks or

deformation

✔

Visual

Undistorted appearance

Display

LEDs

Legibility

✔

Visual

All LED segments work