Rework on ball grid array (bga) ics – HP LT3200 User Manual

Page 10

HP High-Definition LCD TV Service Manual

5

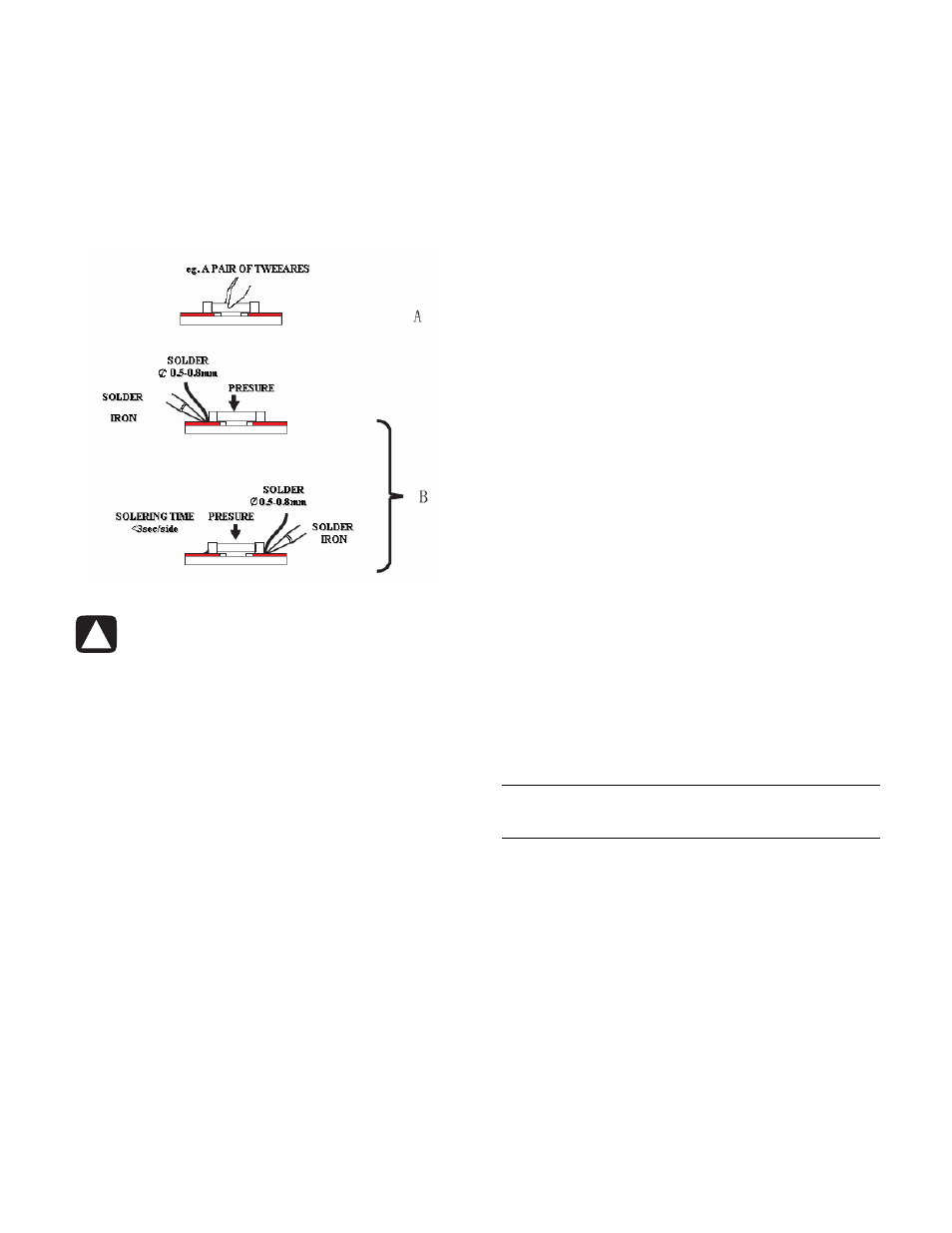

Attachment of SMDs

1 Locate the SMD on the solder lands by means of

tweezers and solder the component on one side.

Ensure that the component is positioned correctly on

the solder lands (A).

2 Complete the soldering of the terminals of the

component (B).

CAUTIONS:

•

When soldering the SMD terminals, do not touch

them directly with the soldering iron. The soldering

should be done as quickly as possible; care must be

taken to avoid damage to the terminals of the SMDs

themselves.

•

Keep the SMD’s body in contact with the printed

board when soldering.

•

The soldering iron to be used (approximately 30 W)

should preferably be equipped with a thermal

control (soldering temperature: 360º to 380º C).

•

Soldering should not be done outside the

solder land.

•

Soldering flux (of rosin) may be used but should not

be acidic.

•

After soldering, let the SMD cool down gradually at

room temperature.

•

The quantity of solder must be proportional to the

size of the solder land. If the quantity is too great,

the SMD might crack or the solder lands might be

torn loose from the printed board.

Rework on Ball Grid Array (BGA) ICs

General information

Although (LF) BGA assembly yields are very high, there

may still be a requirement for component rework. By

rework

, we mean the process of removing the

component from the PWB and replacing it with a new

component. If an (LF) BGA is removed from a PWB, the

solder balls of the component are deformed drastically

so the removed (LF) BGA has to be discarded.

Device removal

As is the case with any component that, it is essential

when removing an (LF) BGA, the board, tracks, solder

lands, or surrounding components are not damaged.

To remove an (LF) BGA, the board must be uniformly

heated to a temperature close to the reflow soldering

temperature. A uniform temperature reduces the

chance of warping the PWB. To do this, we

recommend that the board is heated until it is certain

that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For

the appropriate temperature profiles, see the IC data

sheet.

Area Preparation

When the component has been removed, the vacant IC

area must be cleaned before replacing the (LF) BGA.

Removing an IC often leaves varying amounts of solder

on the mounting lands. This excessive solder can be

removed with either a solder sucker or solder wick. The

remaining flux can be removed with a brush and

cleaning agent. After the board is properly cleaned

and inspected, apply flux on the solder lands and on

the connection balls of the (LF) BGA.

NOTE:

Do not apply solder paste, as this has shown to

result in problems during resoldering.

Device replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF) BGA should

be aligned under a microscope or magnifying glass. If

this is not possible, try to align the (LF) BGA with any

board markers. To reflow the solder, apply a

temperature profile according to the IC data sheet. To

avoid damaging neighboring components, it may be

necessary to reduce some temperatures and times.