Please read the following carefully – Harbor Freight Tools 93212 User Manual

Page 31

Page 31

For technical questions, please call 1-800-444-3353.

SKU 93212

PLease read the FoLLoWing careFuLLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED

TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY

CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT

PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

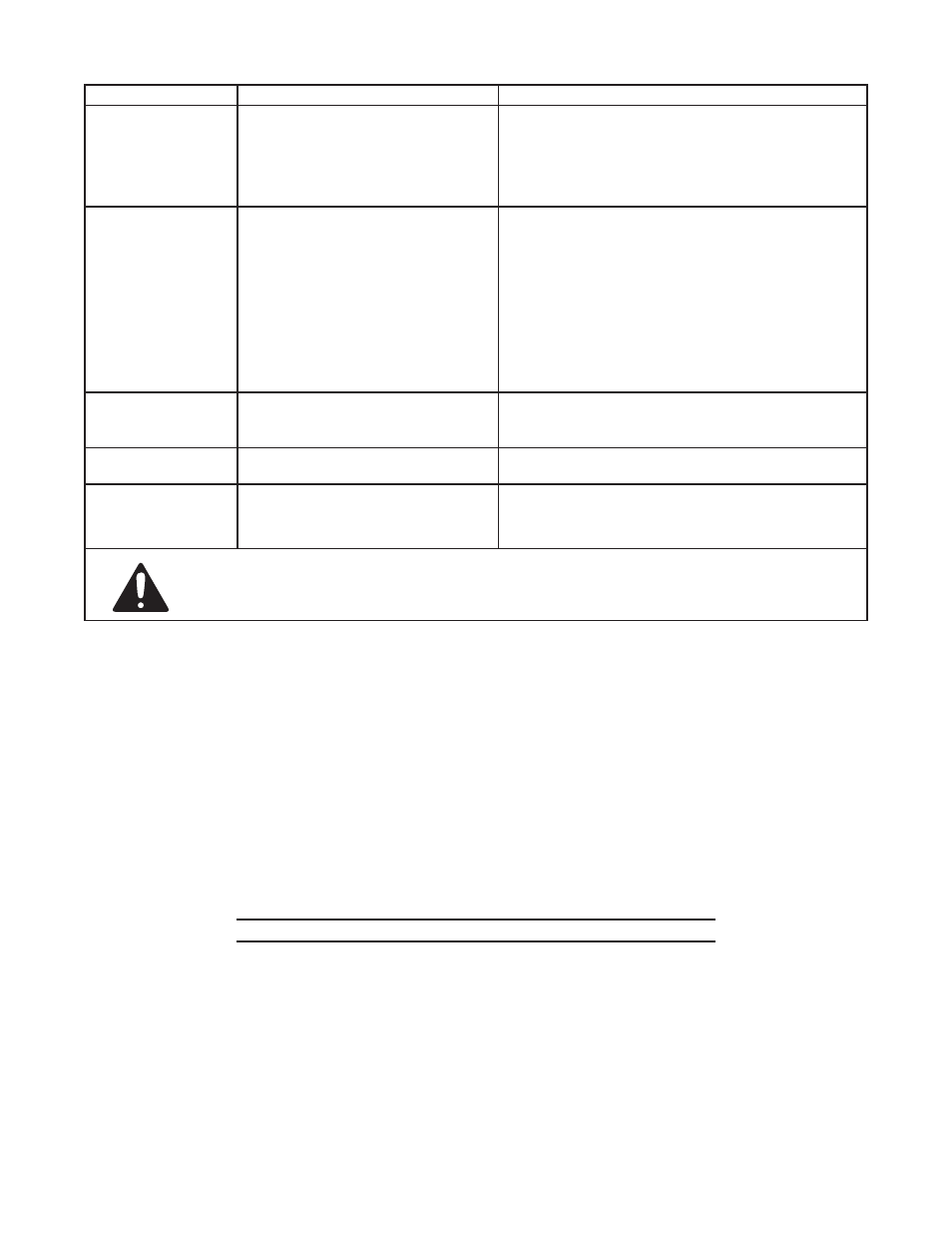

Problem

Possible causes

Likely solutions

Difficulty moving

Cranks of Cross

Slide, Compound

Slide and/or

Carriage Handwheel.

Debris jammed around Gibs.

1.

Gibs adjusted too tight.

2.

Bedways need lubrication.

3.

Remove Gibs, clean Gibs and all adjacent areas.

1.

Re-lubricate, then reinstall Gibs.

Loosen Gib screws (99 and/or 106) and lubricate

2.

bedways.

Lubricate bedways.

3.

Cutting Tool

or machine

components vibrate

excessively during

operation.

Tool Post (112) too loose.

1.

Cutting tool jutting too far out of

2.

Tool Post or not secure.

Gibs need adjustment.

3.

Cutting tool need sharpening.

4.

RPM or feed rate incorrect for

5.

job.

Clean any debris around Tool Post, then securely

1.

tighten Tool Post.

Remove and reinstall cutting tool so that at least

2.

two screws hold it securely in place and no more

than 1/3 of the tool extends beyond the Tool Post.

Adjust Gib screws (99 and/or 106).

3.

Sharpen or replace tool.

4.

Check and adjust for recommended RPM and/or

5.

feed rate.

Finished piece

uneven from one

end to the other.

Chuck and Tailstock are not aligned. Realign Tailstock following Tailstock Alignment

instructions in the maintenance section of this

manual.

Difficulty moving

Chuck Jaws.

Debris lodged between Jaws and

Chuck.

Remove Jaws. Clean and lubricate Chuck threads,

then reinstall Jaws.

Carriage will not

feed.

Gear or gears not engaged.

1.

Damaged gears.

2.

Feed Handle screw loose.

3.

Check gears and adjust positions.

1.

Check and replace damaged gears.

2.

Tighten feed handle screw.

3.

Follow all safety precautions whenever diagnosing or servicing the tool.

disconnect power supply before service.

reV 10b