Troubleshooting, Motor and electrical – Harbor Freight Tools 93212 User Manual

Page 29

Page 29

For technical questions, please call 1-800-444-3353.

SKU 93212

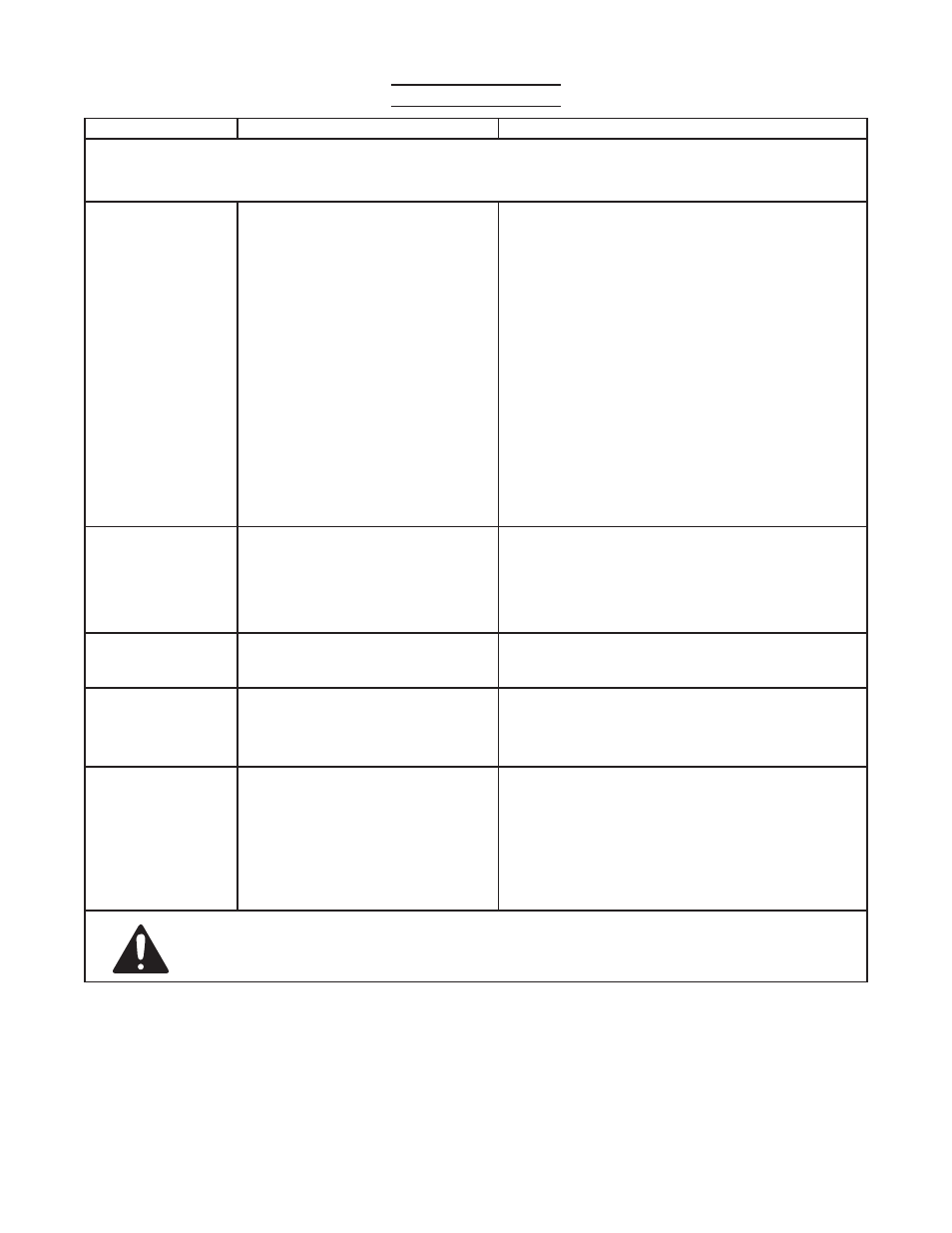

troubleshooting

Problem

Possible causes

Likely solutions

Motor and Electrical

Lathe will not start

or a breaker trips on

startup.

Cord not connected.

1.

No power at outlet.

2.

Fuse has blown.

3.

Chuck Guard safety interlock not

4.

in place.

PC Board (182) faulty.

5.

Power Switch (178), Forward/

6.

OFF/Reverse Switch (181) and/

or Speed Control Knob (180) not

working.

Internal damage or wear. (such

7.

as wiring or motor.)

Check that cord is plugged in.

1.

Check power at outlet. If outlet is unpowered,

2.

turn off tool and check circuit breaker. If breaker

is tripped, make sure circuit is right capacity for

tool and circuit has no other loads.

Check for short, replace fuse (see Maintenance

3.

section of this manual).

Rotate Pin (251) so it seats in Plate (252).

4.

Inspect PC Board, have replaced if needed.

5.

Check and replace as needed.

6.

Have technician service tool.

7.

Lathe stalls.

Incorrect workpiece material

1.

(metal).

Drive Pulleys slipping on shaft.

2.

Removing too much material per

3.

pass.

Use metal suited for Lathe.

1.

Tighten or Replace Pulleys (27,148).

2.

Remove less material per pass.

3.

Lathe operates

slowly.

Extension cord too long or wire size

too small.

Eliminate use of extension cord. If an extension

cord is needed, use shorter/heavier gauge cord.

See Extension Cords in GROUNDING section.

Performance

decreases over time.

Accessory dull or damaged.

1.

Carbon Brushes (318) worn or

2.

damaged.

Keep cutting accessories sharp. Replace as

1.

needed.

Replace Carbon Brushes (See Maintenance

2.

section of this manual).

Excessive noise or

rattling.

Pulley setscrews missing or

1.

loose.

Motor fan hitting cover.

2.

Belt (if equipped) too loose

3.

(slipping) or too tight (bearing

damage).

Internal motor damage or wear.

4.

Check Pulley keys and setscrews. Replace or

1.

tighten as needed.

Tighten fan cover or replace as needed.

2.

Properly tension belt.

3.

Have technician service tool.

4.

Follow all safety precautions whenever diagnosing or servicing the tool.

disconnect power supply before service.

reV 10b