Assembly instructions – Harbor Freight Tools 93212 User Manual

Page 12

Page 12

For technical questions, please call 1-800-444-3353.

SKU 93212

asseMBLY instructions

note: For additional information regarding the

parts listed in the following pages, refer

to the Assembly Diagram near the end of

this manual.

1.

Warning! Make sure the Power

Switch of the tool is in its “OFF” position

and that the tool is unplugged from

its electrical outlet before making any

adjustments to the tool.

Clean off the protective grease on the

2.

Mini Lathe.

attaching rubber Feet or

installing to Workbench

note: Mount or place the Lathe on a sturdy

workbench or table, with good lighting,

at a height that allows you to comfortably

work without back strain.

The Lathe can be mounted permanently

to a workbench or used with it’s included

Rubber Feet (125) on a tabletop.

to attach the rubber Feet:

Figure 4

Rubber Feet (125)

Chip Tray (126)

Bolts (67)

Bolts (67)

To attach the Rubber Feet to the bottom

of the Lathe, unthread the Bolts (67)

from the bottom of the Chip Tray (126).

Slide the Rubber Feet onto the Bolts

and re-thread them into the bottom of

the Lathe through the Chip Tray holes.

Tighten securely.

to Mount the Lathe to a Workbench:

Figure 5

14-7/8”

Drill holes for permanent mounting:

2-7/8”

Unthread the Bolts (67) from the bottom

of the unit. Measure and drill holes in the

workbench. Use appropriate length M6-1

bolts and washers (sold separately) to

secure the Lathe and Chip Tray to the

workbench.

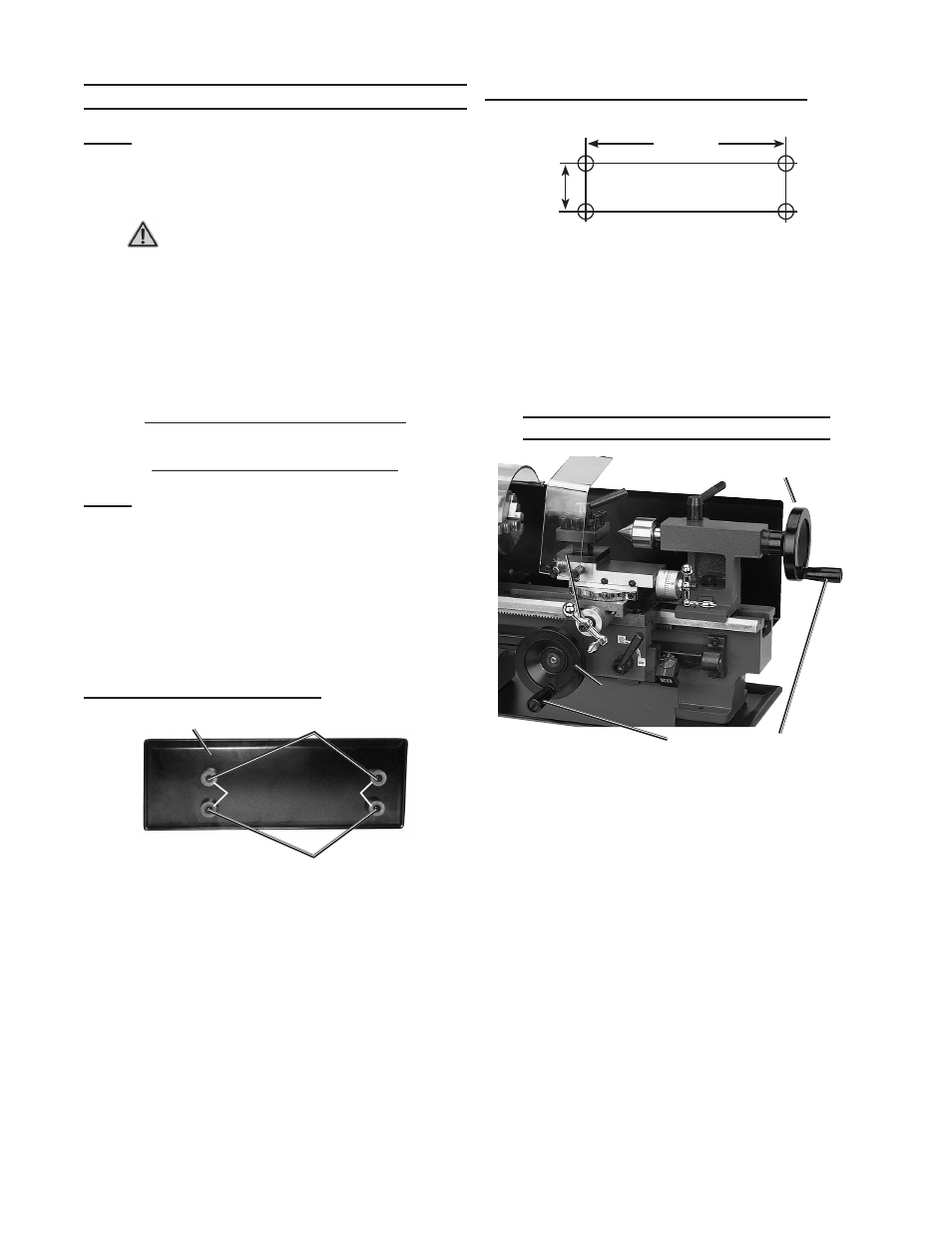

installing handwheel handles

Figure 6

Handwheel Handles

Tailstock Quill Control Wheel (84a)

Feed Control Wheel (84b)

Cross Slide

Crank (86a)

1. To install the Handwheel Handles on the

Tailstock Quill Control Wheel (84a) and

the Feed Control Wheel (84b), use a

flathead screwdriver and a 14mm open

end wrench to thread the handles onto

the wheels.

For packaging purposes, the Cross Slide

2.

Crank (86a) is shipped from the factory

facing backwards. Adjust the Cross Slide

Crank (86a) to face forward using a 5mm

Hex Wrench (part of 311) to unthread the

Cap Screw (52) and turn the Cross Slide

Crank around. Tighten the Cap Screw

securely.

reV 10b