Maintenance and servicing – Harbor Freight Tools 93212 User Manual

Page 25

Page 25

For technical questions, please call 1-800-444-3353.

SKU 93212

Maintenance and

serVicing

Procedures not specifically

explained in this manual must

be performed only by a qualified

technician.

to PreVent

serious inJurY

FroM accidentaL

oPeration:

turn the Power switch of the tool

to its “oFF” position and unplug

the tool from its electrical outlet

before performing any

inspection, maintenance, or

cleaning procedures.

to PreVent serious inJurY

FroM tooL FaiLure:

do not use damaged equipment.

if abnormal noise or vibration

occurs, have the problem

corrected before further use.

cleaning, Maintenance, and

Lubrication

BeFore each use,

1.

inspect the

general condition of the tool. Check for

loose hardware, misalignment or binding

of moving parts, cracked or broken parts,

damaged electrical wiring, and any

other condition that may affect its safe

operation.

aFter use,

2.

wipe external surfaces of

the tool with clean cloth.

3.

Warning! if the supply cord of

this power tool is damaged, it must be

replaced only by a qualified service

technician.

Belt inspection and tensioning

Remove belt cover, if equipped.

1.

Examine belt for cracks, tears in the

2.

backing, or other damage. Replace belt

if damaged according to steps below:

Loosen the motor mounting bolts and

a.

slide the motor towards the other pulley

as far as possible.

Slide the old belt off of the smallest

b.

pulley first, then remove it.

Put the new belt around the larger

c.

pulley first, then around the smaller

pulley.

Move the motor away from the other

d.

pulley until it is properly tensioned

according to the directions below.

Tighten the motor mounting bolts.

Check and adjust belt tension according

3.

to the steps below:

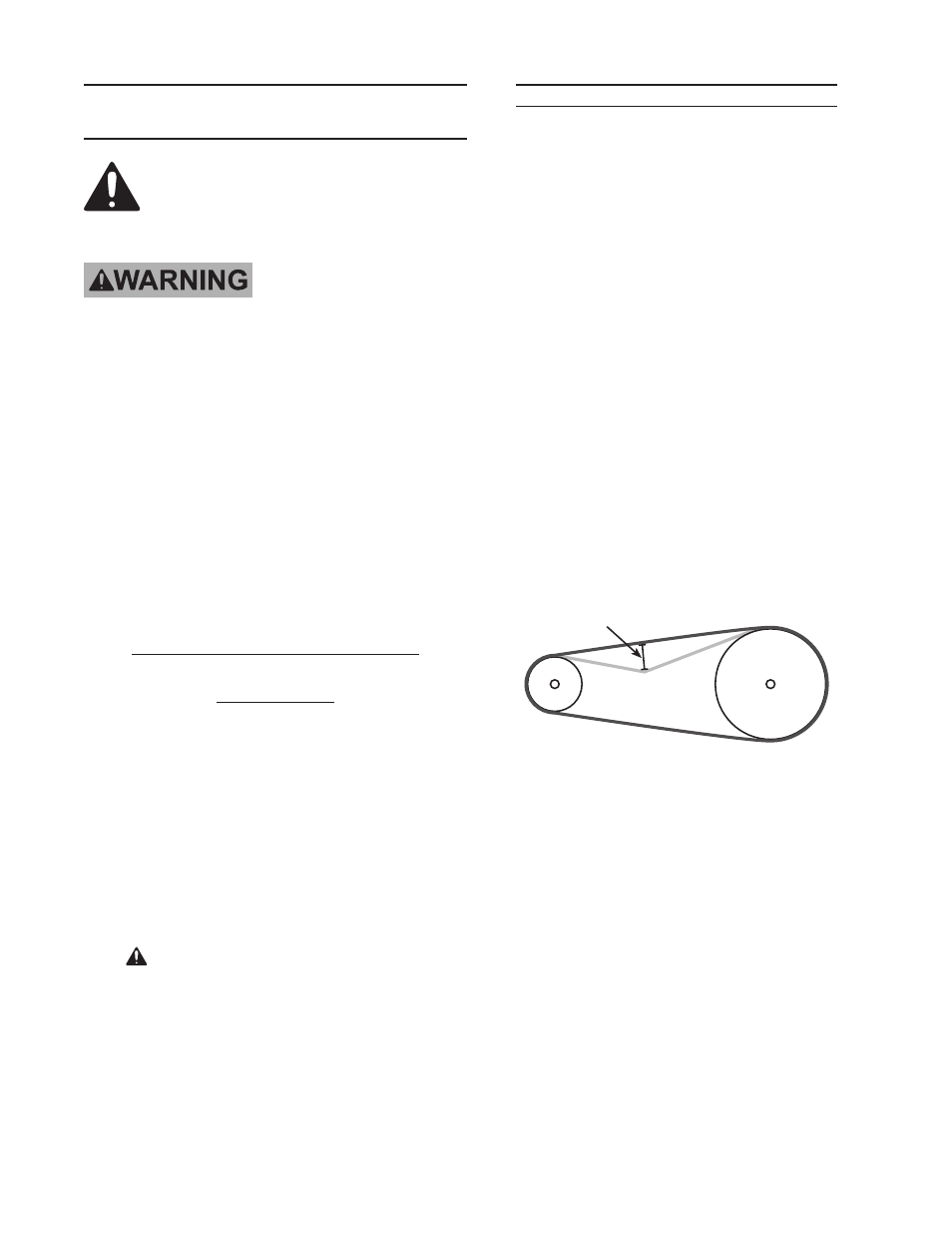

Deflection

distance

Press on the center of the longest

a.

span on the belt with moderate finger

pressure. Then measure the deflection

distance, the distance that the belt

moved. The belt should deflect about

1/4”.

If the belt deflects too much,

b.

tighten

belt by loosening the motor mounting

bolts and moving the motor away from

the other pulley slightly. Secure motor

mounting bolts and retest tension. If the

belt is too long to be properly tensioned,

it must be replaced.

If the belt deflects too little,

c.

loosen

belt by loosening the motor mounting

reV 10b