Eagle Electronics FishElite User Manual

Page 39

31

Recommended tools for this job include: drill, 5/8" or 7/8" drill bit, 1/8" drill

bit for pilot holes, screwdriver. Required supplies for this job include: four

#8 stainless steel wood screws (3/4" long), high quality, marine grade

above- or below-waterline sealant. Some equipment depends on your sen-

sor model. See page 32 for details.

First find a location on the boat's transom where the water flow is smooth-

est. Don't mount the sensor behind strakes or ribs. These will disturb the

water flow to the speed sensor. Make sure the sensor will remain in the

water when the boat is on plane. Also make sure the location doesn't inter-

fere with the boat's trailer. Typically, the sensor is mounted about one foot

to the side of the transom's centerline.

Once you've determined the proper location for the unit, place the sen-

sor on the transom. The bottom of the bracket should be flush with the

hull's bottom. Using the sensor as a template, mark the hull for the

screws' pilot holes. Drill four 1/8" holes, one in each end of the slots.

Mount the sensor to the hull using #8 stainless steel wood screws (not

included). Use a high quality, marine grade above- or below-waterline

sealant to seal the screws. Make sure the sensor is flush with the bot-

tom of the hull and tighten the screws.

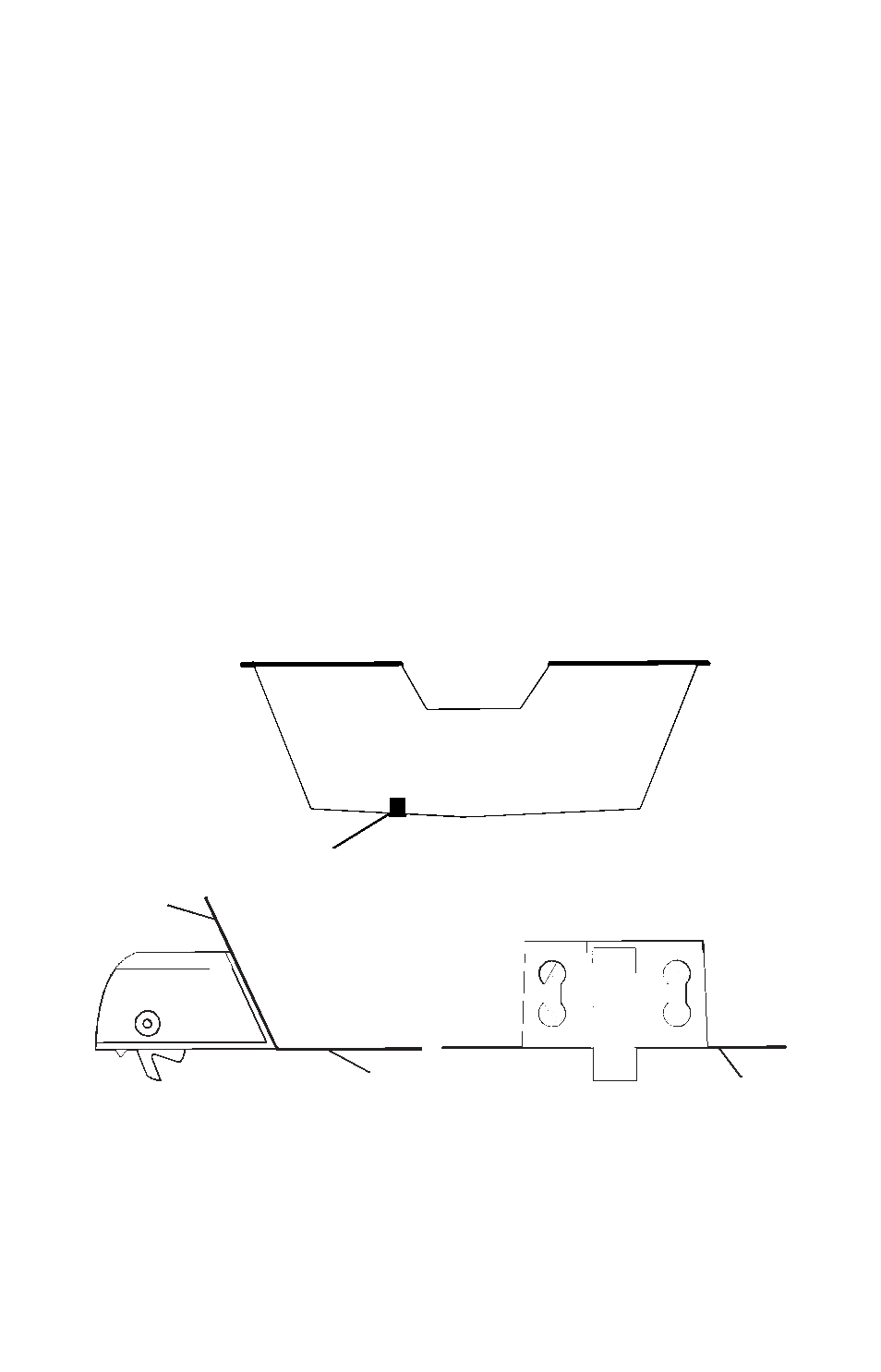

Stern view showing good location for mounting sensor on transom.

Speed sensor mounting configuration:

side view (left) and rear view (right.)

If the base of the transom has a radius, fill the gap between the tran-

som and the sensor with the sealant. This will help ensure a smooth

water flow.

Good location

Transom

Bottom of hull

Bottom of hull