Parts list – RKI Instruments Eagle Series User Manual

Page 69

Eagle Instruction Manual

Appendix C: Non-Standard Toxic Gas Sensors • 62

sensor if necessary.

1. Take the Eagle to a non-hazardous location, and turn the power

off.

2. Unscrew the two large screws on the top of the case, then carefully

lift the top of the case and lay it aside.

3. In the front half of the bottom case, locate the sensor you want to

replace. The sensor with wires connected to EC3 on the analog

PCB displays its reading on the third line of the screen. The sensor

connected to EC4 on the analog PCB displays its reading on the

fourth line of the screen.

4. Remove the two screws at the base of the bracket.

5. Lift the sensor assembly up enough to remove the flow adapter

(two screws). The flow adapter is attached to the sensor.

CAUTION:

Avoid pulling on sensor wires. Always unplug at the connector.

6. Disconnect the connector from the analog PCB. Note to which

socket (EC3 or EC4) the connector is connected.

7. Remove the sensor assembly from the instrument case.

8. Remove the two screws that secure the sensor assembly to the

bracket.

9. Remove the two screws that secure the sensor to the amplifier,

then remove the sensor from the amplifier. Retain the amplifier for

use with the replacement sensor.

10. Install the replacement sensor in reverse order.

NOTE:

Allow up to 4 hours after you replace a non-standard toxic

gas sensor, or if charged batteries have not been installed for

an extended period, for the channel to show a normal

response, then calibrate the sensor.

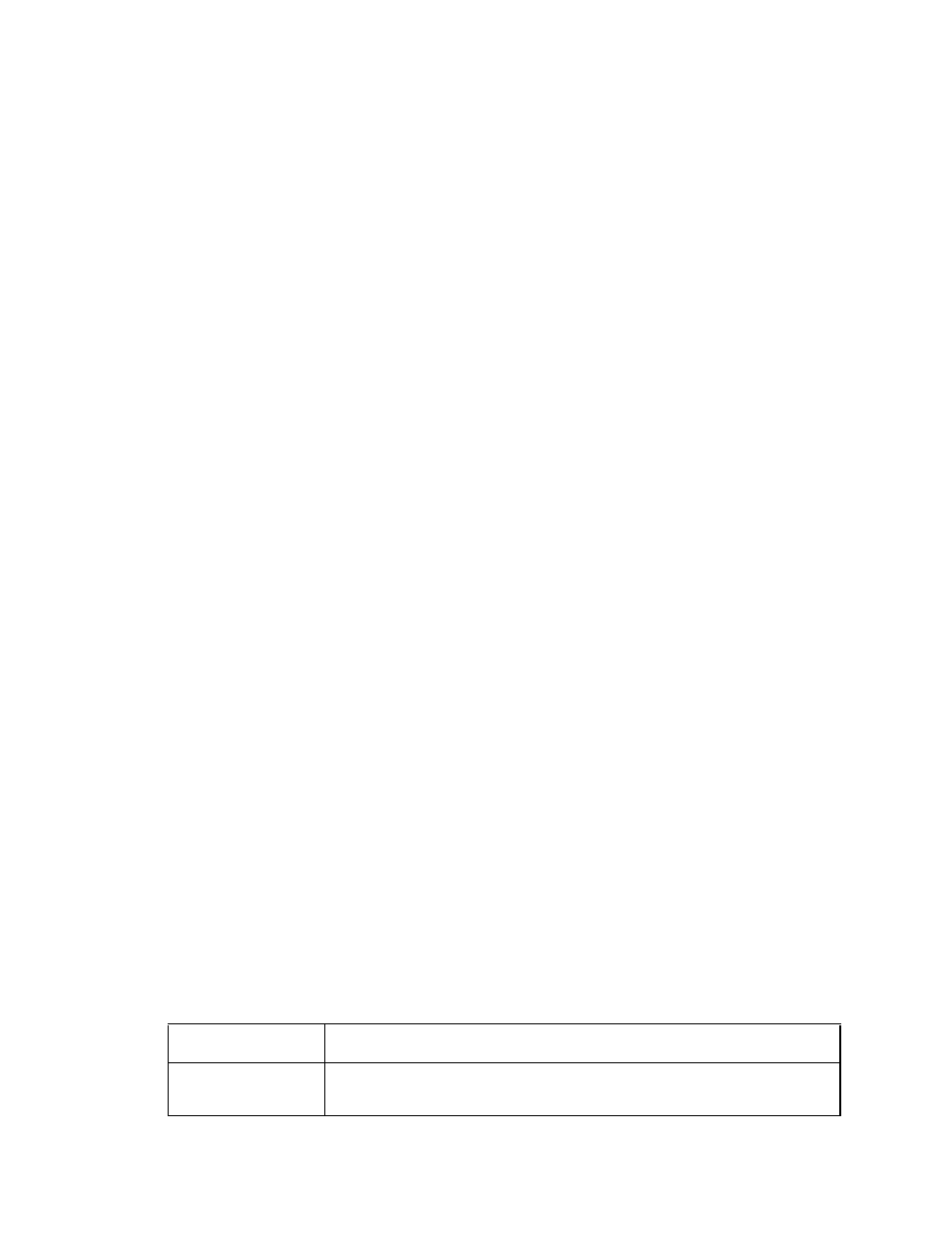

Parts List

Table 9 lists part numbers for replacement parts and accessories of the

Eagle’s non-standard toxic gas sensors.

Table 9: Parts List: Non-Standard Toxic Gas Sensors

Part Number

Description

06-1273RK

Tubing, 1/4 in. x 1/8 in. PTFE (order by foot; 3 ft. standard;

consult RKI Instruments, Inc., for lengths longer than 3 ft.)