Save these instructions for future use, Specifications, English – DeWalt DW744 User Manual

Page 6

2

•

WHEN changing saw location, disconnect power.

•

USE extra caution when the guard assembly is removed

for resawing, dadoing, rabbeting, or molding. Replace

the guard as soon as that operation is completed.

•

NEVER hold onto or touch the “free end” of the workpiece

or a “free piece” that is cut off, while power is ON and/or

the saw blade is rotating.

•

IF YOU STALL OR JAM the saw blade in the workpiece,

turn saw OFF, remove the workpiece from the saw blade,

and check to see if the saw blade is parallel to the miter

gauge slots or grooves and if the splitter is in proper

alignment with the saw blade. If ripping at the time, check

to see if the rip fence is parallel with the saw blade.

Readjust as indicated.

WARNING: Do not allow familiarity (gained from frequent

use of your saw) to replace following safety rules. Always

remember that a careless fraction of a second is sufficient

to inflict severe injury.

•

MAKE SURE your fingers do not contact the terminals of

the power cord when installing or removing the plug to or

from the line power source.

•

KICKBACKS - Kickbacks can cause serious injury. A

kickback occurs when a part of the workpiece binds

between the saw blade and the rip fence, or other fixed

object, and rises from the table and is thrown toward the

operator. Kickbacks can be avoided by attention to the

following conditions:

KICKBACKS—HOW TO AVOID THEM AND

PROTECT YOURSELF FROM POSSIBLE INJURY.

a)

Be certain that the saw blade is parallel to the rip fence.

Adjust fence if not parallel.

b)

Do not rip by applying the feed force to the section of

the workpiece that will become the cut-off (free) piece.

Feed force when ripping should always be applied

between the saw blade and the fence…use a push

stick for short work, 6" (152mm) wide or less. For less

than 2" (51mm) wide, you must use a special fixture.

c)

Keep saw blade guard, splitter and anti-kickback teeth

in place and operating properly. Keep teeth sharp. If

teeth are not operational, return your unit to the

nearest D

E

WALT Service Center for repair. The

splitter must be in alignment with the saw blade and the

teeth must stop a kickback once it has started. Check

their action before ripping by pushing the wood under

the anti-kickback teeth. The teeth must prevent the

wood from being pulled toward the front of the saw.

d)

Plastic and composition (like hardboard) materials may

be cut on your saw. However, since these are usually

quite hard and slippery, the anti-kickback teeth may not

stop a kickback. Therefore, be especially attentive to

following proper set up and cutting procedures for

ripping.

e)

Use saw blade guard and splitter for every operation for

which it can be used, including all through sawing.

•

DO NOT leave a long board (or other workpiece)

unsupported so the spring of the board causes it to shift

on the table. Provide proper support for the workpiece,

based on its size and the type of operation to be

performed. Hold the work firmly against the fence and

down against the table surface.

•

NEVER use a length stop on the free end of the

workpiece when crosscutting. Never hang onto or touch

the free end of the workpiece when crosscutting, or a free

piece that is cut off when ripping while power is ON and/or

the saw blade is rotating. In short, the cut-off piece in any

“thru-sawing” (cutting completely through the workpiece)

operation must never be confined — it must be allowed to

move away from saw blade.

•

IF YOUR SAW makes an unfamiliar noise or if it vibrates

excessively, cease operating immediately until the source

has been located and the problem corrected.

•

KEEP OUT of the line of saw blade. Stand to the side

whenever possible.

•

USE a push-stick when required. (See page 9)

•

PAY particular attention to instructions on reducing risk of

kickback.

•

DO NOT perform any operation free hand.

•

NEVER reach around, behind or over saw blade.

•

USE RECOMMENDED ACCESSORIES. The use of

improper accessories may cause risk of personal injury.

WARNING:

Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals

are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Specifications

Horsepower

2-1/2

Table Size

19 1/4" x 26 1/2"

Miter Angle

30° L&R

Bevel Angle

0° to 45°L

Blade Size

10" (254mm)

Max. Cut Depth

0° Bevel ................3 1/8" (79mm)

Max. Cut Depth

45° Bevel ..............2-1/4" (57mm)

RPM, no load

3650

English

1

4

2

3

6

5

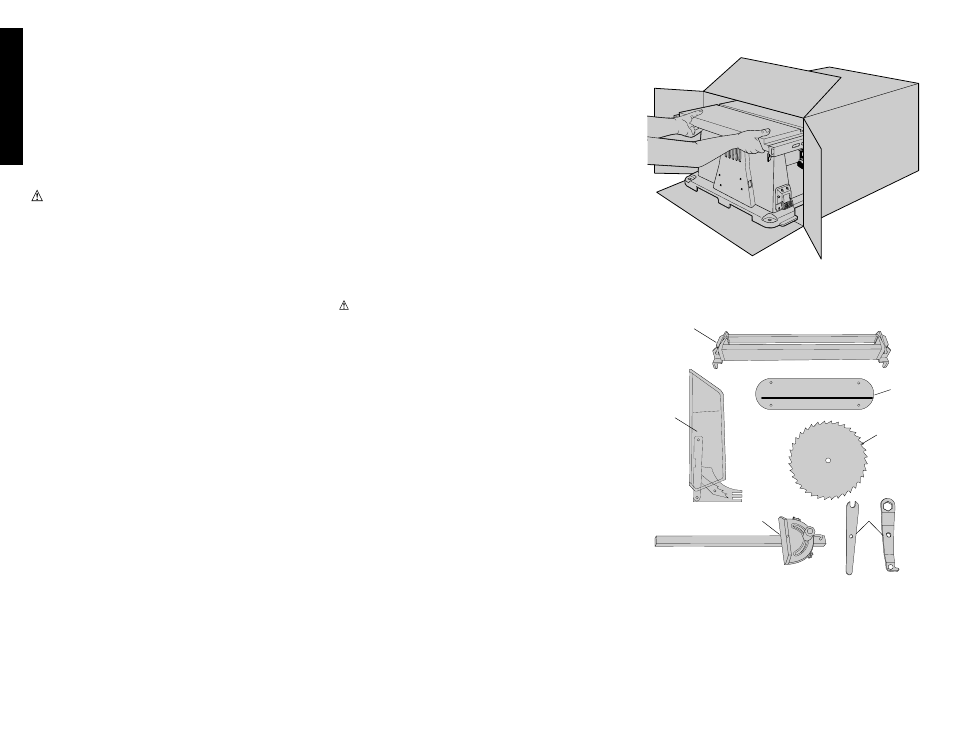

FIG. 2

FIG. 1