On-off switch, Adjustments, Saw blades – DeWalt DW744 User Manual

Page 10: English

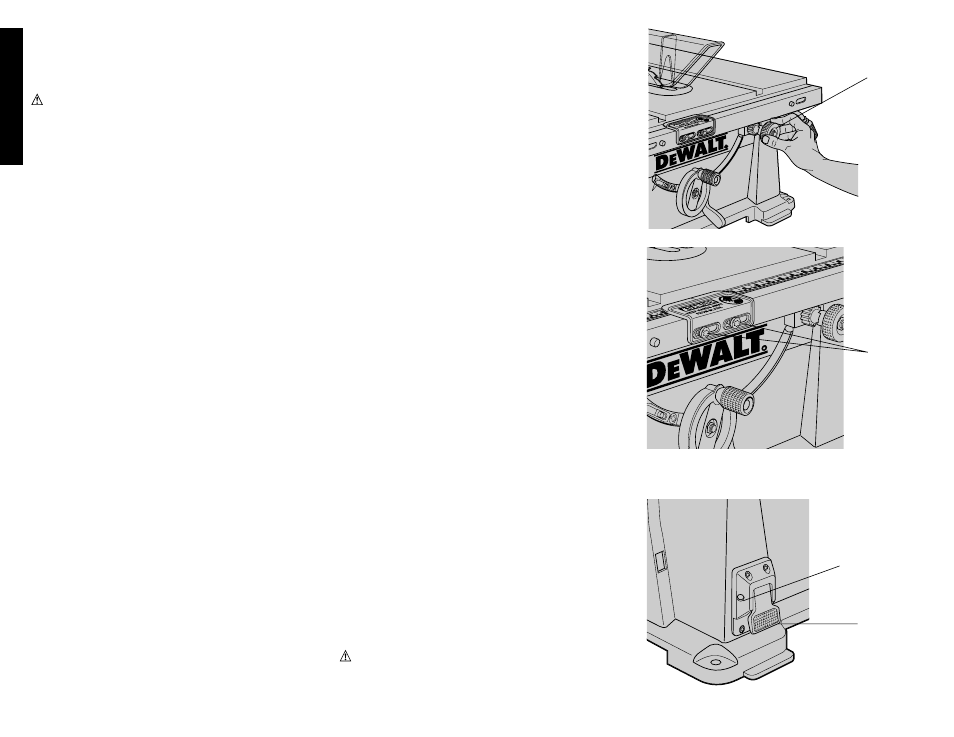

On-Off Switch

Lift the switch paddle up to turn your saw ON and push it

down to turn your saw OFF.

A hole is provided in the switch for insertion of a padlock to

lock the saw off (Figure 17).

WARNING: Be sure switch is in the OFF position before

plugging machine in.

Adjustments

NOTE: All settings on your saw have been accurately

adjusted at the factory.

RAIL LOCK ADJUSTMENT

1. Lock the rail lock lever (Figure 9) by pushing down.

2. On the underside of your saw, tighten the nut shown in

Figure 18. Adjust this nut until the gap between the

belville washers closes.

3. Once the springs are almost touching, tighten the nut

1/2 turn.

RIP SCALE ADJUSTMENT

See “ADJUSTING THE RIP SCALE” on page 4.

ADJUST BLADE ALIGNMENT TO TABLE

1. THE SAW MUST BE UNPLUGGED BEFORE YOU

MAKE ANY ADJUSTMENT TO THE BLADE.

2. Place the unit in an upright position. Using a 10mm

socket, loosen rear pivot bracket fasteners just enough

to allow the bracket to move side-to-side.(Figure 8)

3. Adjust the bracket until the blade is parallel to the miter

gauge slot.

4. Tighten the rear pivot bracket fasteners to 7-8 ft.lbs.

BEVEL STOP AND POINTER ADJUSTMENT

1. Raise the blade fully by rotating the blade height

adjustment wheel clockwise until it stops.

2. Unlock the bevel lock lever (Figure 3) by pushing it up

and to the right. Loosen the bevel stop screw

(Figure 19).

3. Place a square flat against the table top and against the

blade between teeth, as shown in Figure 20. Ensure

the bevel lock lever is in its unlocked, or up, position.

4. Using the bevel lock lever, adjust the bevel angle until it

is flat against the square.

5. Tighten the bevel lock lever by pushing it down.

6. Turn the bevel stop cam until it firmly contacts the

bearing block. Tighten the bevel stop screw.

7. Check the bevel angle scale. If the pointer does not read

0°, loosen pointer screw (see Figure 19) and move the

pointer so it reads correctly. Retighten the pointer screw.

8. Repeat at 45°, but do not adjust pointer.

MITER GAUGE ADJUSTMENT

Your miter gauge features adjustable stops at 90° and 45°

left and right. To adjust these stops, loosen the lock nuts

and tighten or loosen the three adjusting screws against the

stop plate (see Figure 21).

FENCE PARALLEL ADJUSTMENT

1. Unlock rail lock lever.

2. Locate rear pinion bearing and loosen the two hex bolts

just enough to allow side-to-side movement.

3. Adjust fence parallel to blade.

4. Lock rail lock lever and check parallel alignment of the

blade.

5. Tighten the 2 hex bolts that secure the rear pinion

bearing assembly to the table.

NOTE: If there is not enough travel in the pinion bearing

assembly to allow the fence to be parallel to the blade,

take the unit to an authorized service center.

RACK AND PINION MESH ADJUSTMENT

Proper adjustment of the rack and pinion mesh is done at

the factory. If it should become necessary to adjust the rack

and pinion mesh, use the following procedure.

1. Turn the saw upside down and locate the front pinion

bearing.

2. Using a narrow blade screw driver or #20 torx driver,

access the screw through the slot. Loosen the screw

(counterclockwise) until the head touches the inside of

the bearing box.

3. Tighten the screw (clockwise) 3/4 of a turn.

4. Repeat procedure for rear pinion bearing.

Saw Blades

THIS SAW IS INTENDED FOR THE USE OF SAW

BLADES 10” IN DIAMETER OR SMALLER

1. The saw blade furnished with your new saw is a 10"

(254mm) combination blade, used for cross cutting

(across the grain) and ripping (with the grain) through

the material. The center hole to fit on the arbor is 5/8"

(16mm) diameter (.625"). This blade will produce a good

quality cut for most applications.

2. There are many types of blades available to do specific

and special jobs such as cross cut only, rip only, hollow

ground, thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe

operating speeds of 5,000 RPM or greater.

4. Saw blades should always be kept sharp. It is

recommended that you locate a reputable sharpening

service to sharpen your blades when needed.

5. Never stack blades on top of one another to store. Place

material such as cardboard between them to keep the

blades from coming in contact with one another.

CAUTION: Abrasive wheels should not be used on this

saw.

English

FIG. 15

FIG. 16

ON-OFF

SWITCH

PADLOCK

INSERTION

HOLE

SCREWS

FINE ADJUST KNOB

FIG. 17

6