Delta Electronics Series Temperature Controller DTD Series User Manual

Page 2

100%

0%

SV-Pb

SV

Proportion band (Pb)

(Output percentage)

Heating process

(Temperature)

100%

0%

SV+Pb

SV

Proportion band (Pb)

(Output percentage)

Cooling process

(Temperature)

The bigger the parameter P, the less possible that the heating will exceed the SV and the longer it will take for the

temperature to reach SV. This is suitable for the control system with faster reaction speed. On the contrary, the

smaller the parameter P, the more possible that the heating will exceed the SV and the shorter it will take for the

temperature to reach SV; however, unstable control is more likely to occur. Smaller P is suitable for the control

system with slower reaction speed.

How to set up the parameter of integration time I

: The bigger the value I, the longer the integration time, as

well as the time to reach the SV. Unstable control is also less likely to occur. On the contrary, the smaller the value I,

the shorter the integration time, as well as the time to reach the SV. Unstable control is thus more likely to occur.

How to set up the parameter of differentiation time D

: The bigger the value D, the faster reaction speed and

repression power DTD has for the external interference. However, if D is too big, the repression power that is also

too big will result in out of control of the situation.

Parameters for PID control: The default integration output volume

is to allow the temperature to fast reach

the SV. The parameter

is for compensating the steady error in PD control. The two parameters are the

output percentages when the input reaches the SV. Assume the output percentage is 20% when PV = SV, the best

setting for this parameter is 20.0. The parameter

can be a reference value when being auto-tuned. It can

also be adjusted manually.

h

PID Programmable Control

!

PID programmable control offers 8 steps for you to plan for the temperature control program. You can set up your

own number of steps and times of execution and directly monitor the current executing step, remaining time and the

current SV. There is only 1 group of PID parameter settings and by the first step, you can directly control the

temperature to the SV. You can also set up the control status that after the program ends, DTD will either stop the

output or stay at the last SV.

Setting up the parameters in the program: To set up the parameters in the program, you have to first enter the initial

setting mode and set the control mode as programmable control

to further display the parameters which

you can set up.

In the operation mode, press

and enter the regulation mode. PV will display the parameter of the number of

steps to be executed

. Maximum 8 steps can be planned in this parameter.

After the setup is completed, press

to display the parameters for setting up the execution loops

. The

range of this parameter is 1 ~ 99, e.g. 2 means executing twice.

Press

to setup the parameter

for the action of DTD after the program ends. Set this parameter as

, indicating that the control output will stop after the program ends. Set this parameter as

, indicating

that DTD will stay at the last step before the program ends.

Press

and display the parameter of SV of step 1

. Use

and

to set up the SV. Next, press

to display the parameter of the executing time of step 1

. Use

and

to set up the time (unit:

minute; Max. 9,999 minutes). After the setup of step 1 is completed, press

to set up the parameters (SV and

executing time) of the next step. Please note that the number of steps is decided by the setting of the parameter

. The number of steps that exceeds the setting will not be displayed on the screen of DTD during the

operation. Press

to return to the operation mode and press

to display the parameter

. Set this

parameter as

and execute the control. DTD does not offer pause function; all executions start from step 1.

In the operation mode, on the SV display, you can monitor the present value (default)

, remaining executing

time

, or the executed number of loops and steps

. Use

to switch between different monitoring

modes and press

to display the selected monitoring mode. When the execution of the program ends, the

remaining executing time will be displayed as “0” and the executed loops and steps as

.

h

Setting up Manual Control

Select manual control in the control mode and set up the control cycle first. Next, press

repeatedly in the

operation mode until

is displayed. Use

and

to modify the output percentage. During the

execution

, the output percentage will vary upon different output percentage settings. The output setting will

be saved and the saved setting will be adopted next time when DTD is switched on. The default setting is 0%.

Alarm Settings!

h

Setting up Alarm Mode

!

DTD offers 9 alarm modes and 4 alarm options. Press

for more than 3 seconds and PV will display the

parameter

. Press

for 6 times to display the parameter

for setting up alarm modes. Use

to select a desired alarm mode. Mode 9 is only available in the programmable control mode. See the table below

for the explanation of every alarm mode.

Mode

Alarm Type

Alarm Output Operation

0 No

alarm

Off

1

Deviation upper- and lower-limit:

Alarm will be enabled when the PV exceeds SV + AL-H or falls below SV -

AL-L.

ON

OFF

SV - (AL-L) SV

SV + (AL-H)

2

Deviation upper-limit:

Alarm will be enabled when the PV exceeds SV + AL-H.

ON

OFF

SV

SV + (AL-H)

3

Deviation lower-limit:

Alarm will be enabled when the PV falls below SV - AL-L.

ON

OFF

SV - (AL-L)

SV

4

Absolute value upper- and lower-limit:

Alarm will be enabled when the PV exceeds AL-H or falls below AL-L.

ON

OFF

AL-L

AL-H

0

5

Absolute value upper-limit:

Alarm will be enabled when the PV exceeds AL-H

ON

OFF

AL-H

0

6

Absolute value lower limit:

Alarm will be enabled when the PV falls below AL-L.

ON

OFF

AL-L

0

7

Hysteresis upper-limit:

Alarm will be enabled when the PV exceeds SV+AL-H and disabled when the PV

falls below SV+AL-L.

SV + (AL-H)

ON

OFF

SV SV + (AL - L)

8

Hysteresis lower-limit:

Alarm will be enabled when the PV falls below SV - AL-H and disabled when the

PV exceeds SV - AL-L.

SV - (AL-H)

ON

OFF

SV

SV - (AL - L)

9

Alarm will be enabled only during the execution of the program.

ON

OFF

Prog. Start

Prog. End

h

Setting up Alarm Option

!

To set up the alarm function, press

after you have set up the alarm mode and the parameter

will be

displayed. Use

to set up the desired option and the parameter to be set will flash. Press

again to

change the setting. When the parameter is flashing, you can press

to move to other digits. Press

to

complete and save the setting. The initial setting of the alarm option is 0000, i.e. all alarm options are not enabled. If

you need to enable all the alarm options, set the parameter to 1111.

Standby alarm output

Set the first digit in right hand side as 1 to enable the standby mode. The

alarm output will be enabled when the PV is SV± 2 and the system is in

execution.

Alarm output inversion

Set the second digit in right hand side as 1, when the alarm output is

enabled, the alarm output contacts will be normally open. When there is no

alarm output, the relay terminals will be short-circuit. Please be noted that

the alarm indicator only relates to whether the control criteria are true and

has nothing to do with the alarm output contact.

Holding alarm output

Set the second digit in left hand side as 1 to hold the alarm output. In this

function, after the alarm output is enabled, the alarm will keep being

enabled unless you stop

the operation of DTD.

Displaying alarm peak

value

Set the first digit in left hand side as 1 to display the peak value. When the

alarm output is enabled, DTD will be able to record the highest and lowest

alarm temperature and display the two values in parameter

and

. Before the alarm is enabled, the parameter will be displayed as

. The values will not be kept after the power of DTD is switched off.

Note: DO NOT use standby alarm, holding alarm and displaying alarm peak values in alarm mode 7, 8 and 9.

h

Exceptions in Alarm Functions

1. When DTD is switched on, in STOP state or alarm mode 0, the alarm will not be enabled and the standby

status will be cleared.

2. Where there is no input sensor connected to DTD or input error, the status of the alarm output will remain.

3. Modifying alarm mode will not clear the standby status. The standby alarm will only be cleared when you STOP

the operation of DTD and re-RUN it again.

Error Display!

Error

Status

Initializing

No Input

Sensor

Connected

Input Signal

Error

Exceeding

Upper Limit

Exceeding

Lower Limit

Exceeding

Setup Range

PV

Flashing

SV

N/A N/A N/A

Note

Initializing.

Displaying

software

version and

the type of

input sensor.

The input

voltage is too

big,

connecting to

empty

terminal, or

incorrect

sensor.

Cannot get

temperature

value, ADC

input error.

The

displayed

value

exceeds

10,999.

The

displayed

value is

smaller than

-1,999.

The input

exceeds

TP-H (Max.

temp), TP-L

(Min. temp),

or the range

of the input

sensor

selected.

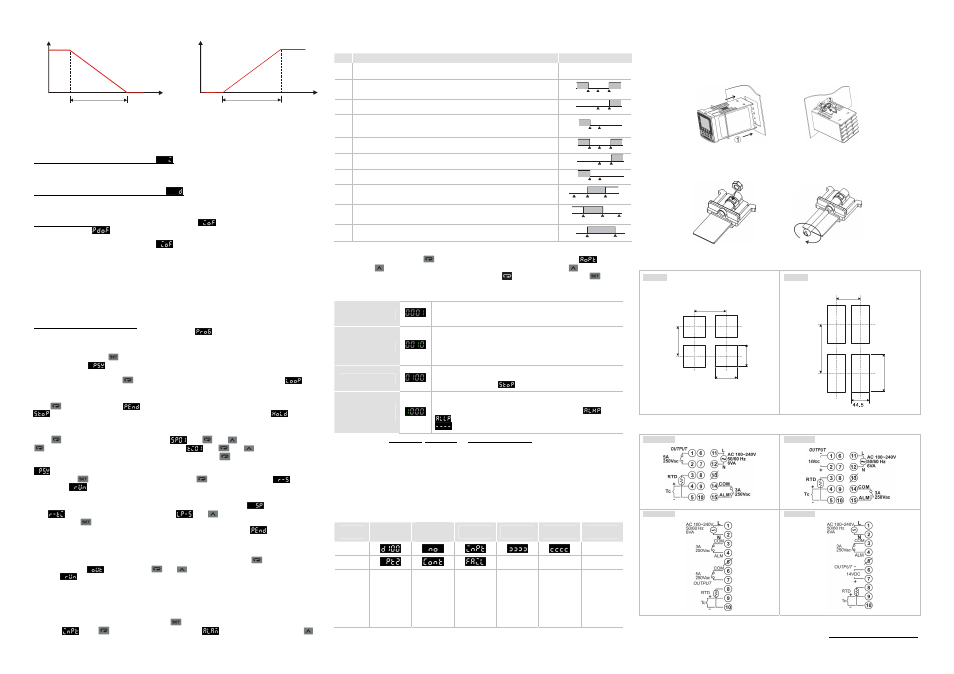

How to Mount

!

1. Insert DTD into the panel cutout.

2. Insert the mounting bracket into the mounting groove at the top and bottom of DTD.

3. Push the mounting bracket forward until the bracket stops at the panel wall.

4. Tighten the screw.

How to Install Mounting Bracket

!

Panel Cutout

!

DTD4848

65.0 min.

6

0

.0

m

in

.

45

+0.6

0

4

5

+

0

.6

0

DTD4896

60.0 min.

1

2

0

.0

m

in

.

+0.6

-0

9

1

.5

+

0

.6

-

0

Terminals

!

DTD4848R0

DTD4848V0

DTD4896R0

DTD4896V0

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or

download the most updated version at http://www.delta.com.tw/industrialautomation