Electrical supply connection, Wiring diagrams – Desa (V) CB36(N User Manual

Page 10

9

www.desatech.com

117437-01

NOTICE: This appliance is equipped with a vent safety

shutoff switch which will shut down the appliance in

case of a venting problem. Do not bypass the vent

safety shutoff switch. If the appliance should shut

down, have a qualifi ed installer, service agency, or

your gas supplier inspect the vent before operating.

ELECTRICAL SUPPLY CONNECTION

WIRING DIAGRAMS

ELECTRICAL SUPPLY CONNECTION

CAUTION: Disconnect the electrical power to the

supply circuit before attempting to connect or service

this appliance.

WARNING: This appliance, when installed must be

electrically grounded in accordance with local code or

in the absence of local code, with the current National

Electric Code, ANSI/NFPA 70, or the Canadian Electric

Code, CSA C22.1.

J-BOX WITH

J-BOX WITH

RECEPTACLE

RECEPTACLE

J-BOX

J-BOX

COVER w/

COVER w/

STRAIN RELIEF

STRAIN RELIEF

J-BOX COVER

J-BOX COVER

SCREW - TAB

SCREW - TAB

RETAINER

RETAINER

J-BOX

J-BOX

COVER w/

COVER w/

STRAIN RELIEF

STRAIN RELIEF

ROMEX

ROMEX

CABLE

CABLE

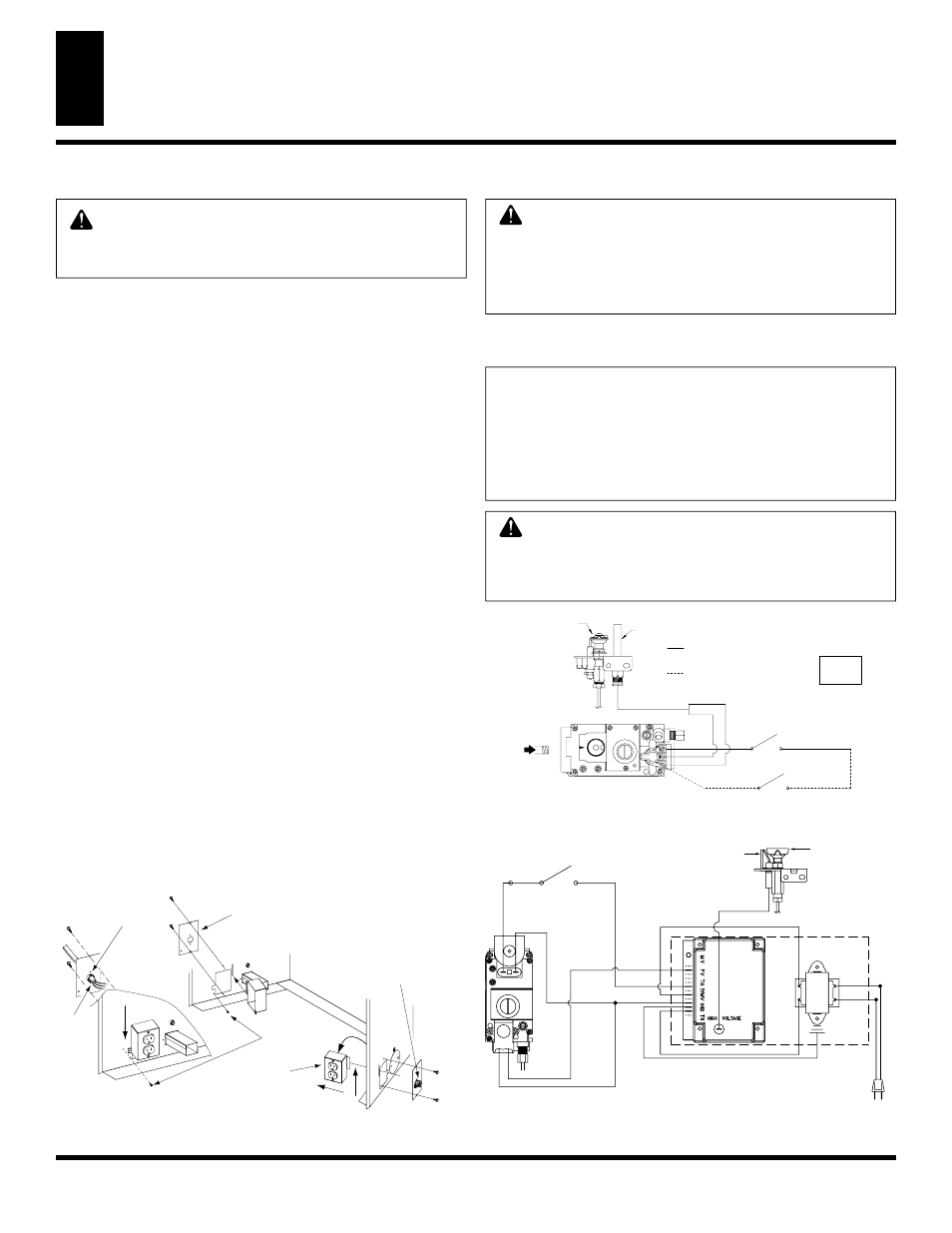

Figure 13 - Relocating Junction Box Receptacle and

Electrical Supply Connection

A pre-wired junction box receptacle with strain relief is provided on the

right side of the cabinet for hard wiring the unit to a 15 Amp, 120VAC,

60Hz grounded branch circuit. If the installation demands that the

electrical supply be connected from the left side, the entire receptacle

box can be relocated to the left side by following these instructions:

Note: If you do not need to relocate the junction box, to connect the

electric supply follow steps 8 through 11 only:

1. Remove the 2 screws and outer cover with strain relief bushing

on the right side of the cabinet (see Figure 13).

2.

Remove inner retaining screw on the junction box mounting tab.

3. Slide the junction box up until the screw mounting tab is lined

up to the notch in the outer cabinet.

4. Swing the junction box out and slip the retaining fl ange out

through the slot in the outer cabinet.

5. Remove the two screws and outer cover on the left side

of the outer cabinet.

6. Reinsert the junction box retaining fl ange through the slot now

on the left side and swing the screw mounting tab back through

the notch as before.

7. Slide the junction box down till the mounting tab holes line up

and replace the inner retaining screw.

8. With the junction box cover removed, pull the end of 3-wire

Romex supply line through the universal strain relief bushing

on the cover. (see Figure 13).

9. Strip back the outer Romex to about 4” and connect the black,

white and green wires accordingly using 3 wire nut connectors.

10. Tuck the tailing wires into the junction box and replace the

junction box cover using the 2 remaining screws.

11. Tighten the adjustment on the universal stran bushing to secure

the Romex sheathing and complete the supply connection.

CAUTION: label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

WIRING DIAGRAMS

Figure 14 - Millivolt Ignition Wiring Diagram

Figure 15 - Electronic Ignition Wiring Diagram

MILLIVOLT WIRING DIAGRAM

SUPPLY

INCOMING

MAIN GAS

BURNER

PILOT

THERMOPILE

EXTERNAL WIRING USE ONLY CLASS 2

THERMOSTAT WIRE 18 GA. RED/WHITE

WALL SWITCH / REMOTE RECEIVER

TH

TP

TH/TP

WHITE

EQUIVALENT OR HIGHER RATING

REPLACE FACTORY WIRING WITH 105°C

RED

TO 120V

CONNECT

DO NOT

HIGH LIMIT

SWITCH

N

O

T

O

L

P

FF

O

I

NC

EV2

EV1

BLACK

BLACK

BLACK

GAS VALVE

HIGH LIMIT

SWITCH

NC

PILOT

BURNER

IGNITOR

ORANGE

RED

RED

BLUE

WHITE

BLACK

TRANSFORMER

GROUND

24 V

A

C

MODULE

IGNITION CONTR

OL

BLUE

GREEN

120 VAC

ELECTRONIC IGNITION

WIRING DIAGRAM

IGNITION MODULE