Delta Electronics Programmable Logic Controller DVP-EH2-L User Manual

M c1 m c2, Mc1 mc2, Warning

Warning

This instruction sheet only provides introductory information on electrical specifications, functions, and wiring. The

program and instructions designed for DVP-EH2-L are compatible with those of DVP-EH2 series, and please refer to

"DVP-PLC Application Manual: Programming”. For how to purchase its peripheral devices, please refer to this

instruction sheet or “DVP-PLC Application Manual: Special Modules".

DVP-EH2-L is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust,

humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device

(e.g. key or specific tools are required for opening the enclosure) in case danger and damage on the device may

occur.

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check all

the wiring again before switching on the power and DO NOT touch any terminal when the power is switched on.

Make sure the ground terminal

is correctly grounded in order to prevent electromagnetic interference.

Introduction

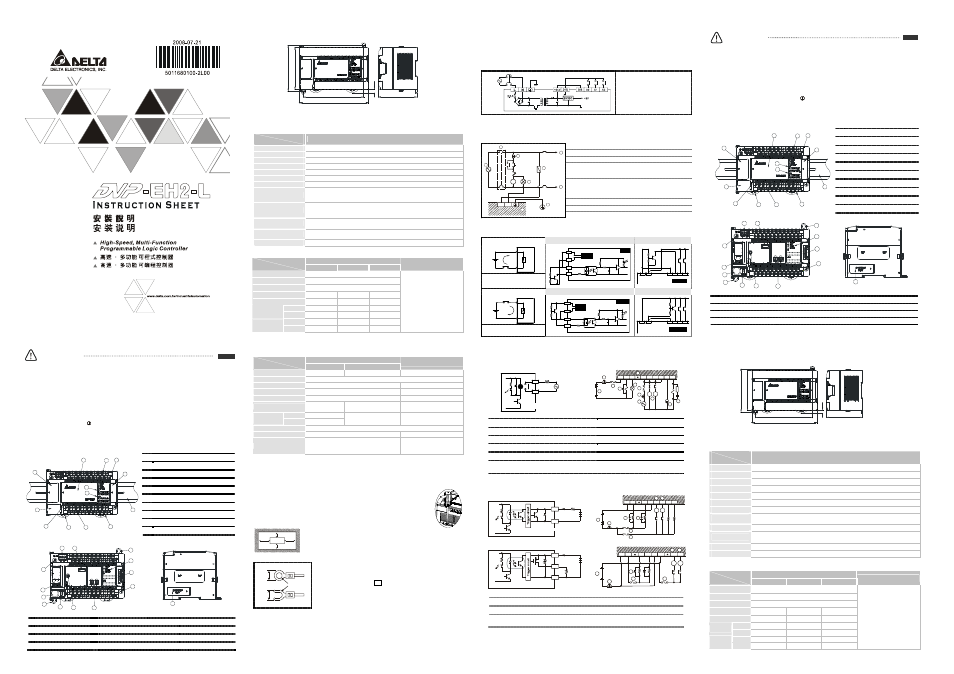

Product Profile & Outline

1

Battery socket cover

2

Function card/memory card cover

3

I/O terminals

4

I/O terminal No.

5

Extension module connection port cover

6

Input indicator

7

Output indicator

8

DIN rail clip

9

Communication port cover

10

5

8

3

8

4

1

2

3

4

6

7

9

10 DIN rail (35mm)

3

1

2

6

7

1

2

5

4

12

9

10

11

8

1 Mounting screw

5 Memory card port

9

COM1 (RS-232)

2 Direct mounting hole

6 POWER/RUN/BAT.LOW/ERROR indicator

10

COM2 (RS-485)

3 Battery socket

7 Extension module connection port

11 Run/Stop switch

4 Function card mounting hole

8 Left-side Extension module connection port

12 VR0/VR1

ENGLISH

Dimension

90

148

7

129.2

98

.2

82.2

Unit: mm

Specifications

Electrical Specification

Model

Item

32EH00

2-L

Power supply voltage

100 ~ 240VAC (-15% ~ 10%); 50/60Hz ± 5%

Fuse capacity

2A/250VAC

Power consumption

60VA

DC24V current supply

500mA

Power protection

DC24V; output short-circuited

Withstand voltage

1,500V AC (Primary-Secondary); 1,500V AC (Primary-PE); 500V AC (Secondary-PE)

Insulation resistance

> 5MΩ (all I/O point-to-ground: 500V DC)

Noise immunity

ESD: 8KV Air Discharge; EFT: Power Line: 2KV, Digital I/O: 1KV, Analog &

Communication I/O: 250V; Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV,

RS: 26MHz ~ 1GHz, 10V/m

Earth

The diameter of grounding wire shall not be less than that of L, N terminal of the power.

(When many PLCs are in use at the same time, please make sure every PLC is properly

grounded.)

Operation/storage

Operation: 0ºC ~ 55ºC (temperature); 50 ~ 95% (humidity); pollution degree 2

Storage: -25 ºC ~ 70 ºC (temperature); 5 ~ 95% (humidity)

Vibration/shock immunity

International standards:IEC61131-2,IEC68-2-6 (TEST Fc)/IEC61131-2 & IEC68-2-27

(TEST Ea)

Weight (g)

R/T: 670/636

Input Point Specification

24VDC single common port input

Specification

Items

10kHz

20kHz

60kHz

Note

Input wiring type

Change wiring from S/S to SINK or SOURCE

Input indicator

LED display; light on = ON, light off = OFF

Input voltage (±10%)

24VDC

Input point configuration

*3

*1

*2

Input impedance

4.7kΩ

3.3kΩ

4.7kΩ

Off On

> 4mA (16.5V)

> 6mA (18.5V)

> 4mA (16.5V)

Active Level

On Off

< 1.5mA (8V)

< 2.2mA (8V)

< 1.5mA (8V)

Off On

< 8us

< 3.5us

< 7.5us

Response time/

noise immunity

On Off

< 60us

< 20us

< 7.5us

*1: The bandwidth of input points

X10, X11, X14, and X15 is

20kHz.

*2: The bandwidth of input points

X0, X1, X4, and X5 is 60kHz.

*3: The bandwidth of the input

points other than the

high-speed input points listed

above is 10kHz.

*4: Input points X0 ~ X7and X10 ~

X17 can conduct 10 ~ 60ms

digital filter adjustment.

Output Point Specification

Single common port transistor output

Specification

Items

Low speed

High speed*

Single common port relay output

Max. frequency

10kHz

200kHz

Load ON/OFF control

Output indicator

LED display; light on = ON, light off = OFF

Min. load

--

2mA/DC power supply

Working voltage

5 ~ 30V DC

< 250V AC, 30V DC

Insulation

Photo coupler isolation

Magnetic isolation

Current specification

0.3A/1 point @ 40ºC

< 1kHz, 0.3A/1 point @ 40°C

≥ 1kHz, 30mA/1 point @ 40°C

2A/1 point (5A/COM)

75VA (conductive), 90W (resistive)

Off On

20us

Max. output

delay time

On Off

30us

0.2us

10ms

Over-current protection

N/A

Mechanical life

N/A

2×10

7

times (without load)

Electrical life

N/A

1.5×10

5

times (5A 30V DC)

5×10

5

times (3A 120V AC)

3×10

4

times (5A 250V AC)

* Only Y0 and Y2 support high-speed output.

Installation & Wiring

3.1 How to Mount & Wiring Notes

How to install DIN rail:

DVP series PLC can be secured to a cabinet by using the DIN rail of 35mm in height and

7.5mm in depth. When mounting PLC to DIN rail, be sure to use the end bracket to stop any

side-to-side movement of PLC and reduce the chance of wires being loosen. A small retaining

clip is at the bottom of PLC. To secure PLC to DIN rail, place the clip onto the rail and gently

push it up. To remove it, pull the retaining clip down and gently remove PLC from DIN rail, as

shown in the figure.

How to screw: Please use M4 screw according to the dimension of the product.

DVP MPU

> 50mm

> 50mm

> 50mm

> 50mm

Please install PLC in an enclosure with sufficient space around it to allow heat

dissipation as shown in the figure.

Wiring:

To suit M3.5 screw terminals

Below 6.2

Below 6.2

1. Use O-type or Y-type terminal. See the figure in the left hand side for its

specification. PLC terminal screws should be tightened to 5 ~ 8 kg-cm (4.3 ~

6.9 in-Ibs) and please use only 60/75ºC copper conductor.

2. DO NOT wire empty terminal • . DO NOT place the input signal cable and

output power cable in the same wiring circuit.

3. DO NOT drop tiny metallic conductor into the PLC while screwing and wiring.

Tear off the sticker on the heat dissipation hole for preventing alien

substances from dropping in, to ensure normal heat dissipation of the PLC.

3.2 Wiring Notes

Power Input Wiring

The power input of DVP-EH2-L PLC is AC. When operating the PLC, please make sure that:

1. The input voltage should be current and its range should be 100 ~ 240V AC. The power should be

connected to L and N terminals. Wiring AC110V or AC220V to +24V terminal or input terminal will result in

serious damage on the PLC.

2. The AC power input for PLC MPU and I/O extension modules should be ON or OFF at the same time.

3. Use wires of 1.6mm (or longer) for the grounding. The power shutdown of less than 10ms will not affect the

operation of the PLC. However, power shutdown time that is too long or the drop of power voltage will stop

the operation of the PLC and all outputs will go OFF. When the power supply turns normal again, the PLC

will automatically return to its operation. Please be aware of the latched auxiliary relays and registers inside

the PLC when programming.

AC Power Input

100~240

VAC

0.5A is the maximum power supply for

+24V power supply output terminal. DO

NOT connect other external power

supplies to this terminal. Every input

terminal requires 6 ~ 7mA to be driven;

e.g. the 16-point input will require

approximately 100mA. Therefore, +24V

cannot give output to extermal load that is

more than 400A.

Safety Wiring

Since a PLC controls many devices, actions of any device may affect actions of other devices, and the

breakdown of any one device may cause the breakdown of the whole auto-control system and danger.

Therefore, we suggest you wire a protection circuit at the power input terminal, as shown in the figure below.

AC power supply load

Power circuit protection fuse (3A

)

Power indicator

Emergency stop

This button can cut off the system power supply when accidental

emergency takes place.

System circuit isolation device

The device is made of electromagnetic contactor and relay as the

switch to prevent the instability of system when the power is

intermittently supplied.

DVP-PLC (main processing unit)

Earth

MC

M C

N

L

1

1

2

3

4

5

6

7

8

Guar d

Limit

M C

Power supply AC: 100 ~ 240VAC

Input Point Wiring

There are two types of DC inputs, SINK and SOURCE.

Input point loop equivalent circuit

Wiring loop

DC Signal IN

S/S

X0

Sinking

SINK mode

(common port for current input S/S)

24VDC

24G

X0

S/S

+24V

SINK

+5V

24G

S/S

X0

X1

X2

+24V

Sink Type

Input point loop equivalent circuit

Wiring loop

DC Signal IN

S/S

X0

Sourcing

SOURCE mode

(common port for current output S/S)

24VDC

24G

X0

S/S

+24V

SOURCE

+5V

24G

S/S

X0

X1

X2

+24V

Source Type

Output Point Wiring

Relay (R) contact circuit wiring

Y0

RY

LED

C0

LOAD

POWER

DVP-**-**-**-R

RELAY OUTPUT

2

3

1

5

C0 Y0 Y1

C1 Y3 Y4 C2 Y6 Y7

4

M C1

M C2

7

10

3

2

8

9

6

Flywheel diode: To extend the life span of contact

Emergency stop: Uses external switch

Fuse: Uses 5 ~ 10A fuse at the common port of output contacts to protect the output circuit

Varistor: To reduce the interference on AC load

Empty terminal: not in use

DC power supply

Neon indicator

A C power supply

Incandescent light (resistive load)

Manually exclusive output: Uses external circuit and forms an interlock, together with the PLC

internal program, to ensure safety protection in case of any unexpected errors.

Transistor (T) contact circuit wiring

Y0

LED

C0

TRANSISTOR OUTPUT

LOAD

1. NPN

< 0.3A

MC1

MC2

2

3

1

C0 Y0

Y1

C1 Y4 Y5 Y6

Y7

5

4

5

3

4

Y0

LED

ZP 0

TRANSISTOR OUTPUT

LOAD

2. PNP

< 0.3A

Up0

MC1

MC2

2

3

1

Up 0 Zp 0

Up 1 Zp 1

Y 1

Y 10

Y0

Y11

3

5

5

4

DC power supply

Emergency stop

Circuit protection fuse

Flywheel diode + inductive load

Manually exclusive output: Uses external circuit and forms an interlock, together with the PLC

internal program, to ensure safety protection in case of any unexpected errors.

注意事項

本使用說明書僅提供電氣規格、功能規格、安裝配線部份說明,其它詳細之程式設計及指令與 DVP-EH2 系列

相容,詳細說明請見 DVP-PLC 應用技術手冊【程式篇】,選購之週邊裝置詳細說明請見該產品隨機手冊或

DVP-PLC

應用技術手冊【特殊模組篇】。

本機為開放型 (OPEN TYPE) 機殼,因此使用者使用本機時,必須將之安裝於具防塵、防潮及免於電擊∕衝

擊意外之外殼配線箱內。另必須具備保護措施(如:特殊之工具或鑰匙才可打開)防止非維護人員操作或意

外衝擊本體,造成危險及損壞。

交流輸入電源不可連接於輸入∕出信號端,否則可能造成嚴重損壞,請在上電之前再次確認電源配線。請勿

在上電時觸摸任何端子。本體上之接地端子

務必正確的接地,可提高產品抗雜訊能力。

產品簡介

產品外觀及各部介紹

1

電池插槽上蓋

2

功能卡∕記憶卡上蓋

3

輸出∕入端子

4

輸入∕輸出端子編號

5

擴充機連接口上蓋

6

輸入點指示燈

7

輸出點指示燈

8

DIN

軌固定扣

9

通訊口上蓋

10

5

8

3

8

4

1

2

3

4

6

7

9

10

固定 DIN 軌糟 (35mm)

3

1

2

6

7

1

2

5

4

12

9

10

11

8

1

機身固定螺絲

5

記憶卡插槽

9 COM1 (RS-232)

2

直接固定孔

6

電源、運行、錯誤及電池狀態指示

10 COM2 (RS-485)

3

電池插槽

7

擴充機連接口

11 Run/Stop

開關

4

功能卡固定孔

8

左側擴充機連接口

12 VR0/VR1

繁體中文

外觀及尺寸

90

14 8

7

129 .2

98

.2

82. 2

尺寸單位:mm

規格

電氣規格

機種

項目

DVP32EH00 2-L

電源電壓

100 ~ 240V AC (-15% ~ 10%); 50/60Hz ± 5%

電源保險絲容量

2A/250V AC

消耗電力

60VA

DC24V

供應電流

500mA

電源保護

DC24V

輸出具短路保護

突波電壓耐受量

1,500V AC (Primary-Secondary); 1,500V AC (Primary-PE); 500V AC (Secondary-PE)

絕緣阻抗

5 M

Ω以上(所有輸出∕入點對地之間 500V DC)

雜訊免疫力

ESD: 8KV Air Discharge; EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O:

250V; Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV, RS: 26MHz ~ 1GHz, 10V/m

接地

接地配線之線徑不得小於電源端 L, N 之線徑(多台 PLC 同時使用時,請務必單點接地)

操作∕儲存環境

操作:0°C ~55°C(溫度),50 ~ 95%(濕度),污染等級 2;

儲存:-25°C ~70°C(溫度),5 ~ 95%(濕度)

耐振動/衝擊

國際標準規範 IEC 61131-2, IEC 68-2-6 (TEST Fc) / IEC 61131-2 & IEC 68-2-27 (TEST Ea)

重量(約), (g)

R/T: 670/636

輸入點規格

24VDC

單端共點輸入

規格

項目

10kHz

20kHz

60kHz

備註

輸入接線型式

由端子 S/S 變換接線為 SINK 或 SOURCE

輸入動作指示

LED

顯示;燈亮表示為 ON,不亮表示為 OFF

輸入信號電壓 (±10%)

24V DC

輸入點配置

*

註 3

*

註 1

*

註 2

輸入阻抗

4.7kΩ

3.3kΩ

4.7kΩ

Off On

> 4mA (16.5V)

> 6mA (18.5V)

> 4mA (16.5V)

動作位準

On Off

< 1.5mA (8V)

< 2.2mA (8V)

< 1.5mA (8V)

Off On

< 8 us

< 3.5 us

< 7.5 us

反應時間

雜訊抑制

On Off

< 60 us

< 20 us

< 7.5 us

*

註 1:輸入點 X10, X11, X14, X15

之頻寬為 20kHz

*

註 2:輸入點 X0, X1, X4, X5 之頻

寬為 60kHz

*

註 3:除上述說明高速輸入點之

外,其餘輸入為 10kHz

*

註 4:輸入點 X0~X17 可作 10 ~ 60

ms

數位濾波調整