Water quality, General, Water treatment – WaterFurnace CLW Chiller User Manual

Page 9: Contaminated water, Strainers

9

CLW QUAD SERIES CHILLER INSTALLATION MANUAL

General

Commercial chiller systems may be successfully applied in a

wide range of commercial and industrial applications. It is the

responsibility of the system designer and installing contractor

to ensure that acceptable water quality is present and that all

applicable codes have been met in these installations.

Water Treatment

Do not use untreated or improperly treated water. Equipment

damage may occur. The use of improperly treated or

untreated water in this equipment may result in scaling,

erosion, corrosion, algae or slime. The services of a qualified

water treatment specialist should be engaged to determine

what treatment, if any, is required. The product warranty

specifically excludes liability for corrosion, erosion or

deterioration of equipment.

The heat exchangers in the units are 316 stainless steel plates

with copper brazing. The water piping in the heat exchanger

is steel. There may be other materials in the building’s piping

system that the designer may need to take into consideration

when deciding the parameters of the water quality.

If an antifreeze or water treatment solution is to be used, the

designer should confirm it does not have a detrimental effect

on the materials in the system.

Contaminated Water

In applications where the water quality cannot be held to

prescribed limits, the use of a secondary or intermediate heat

exchanger is recommended to separate the unit from the

contaminated water.

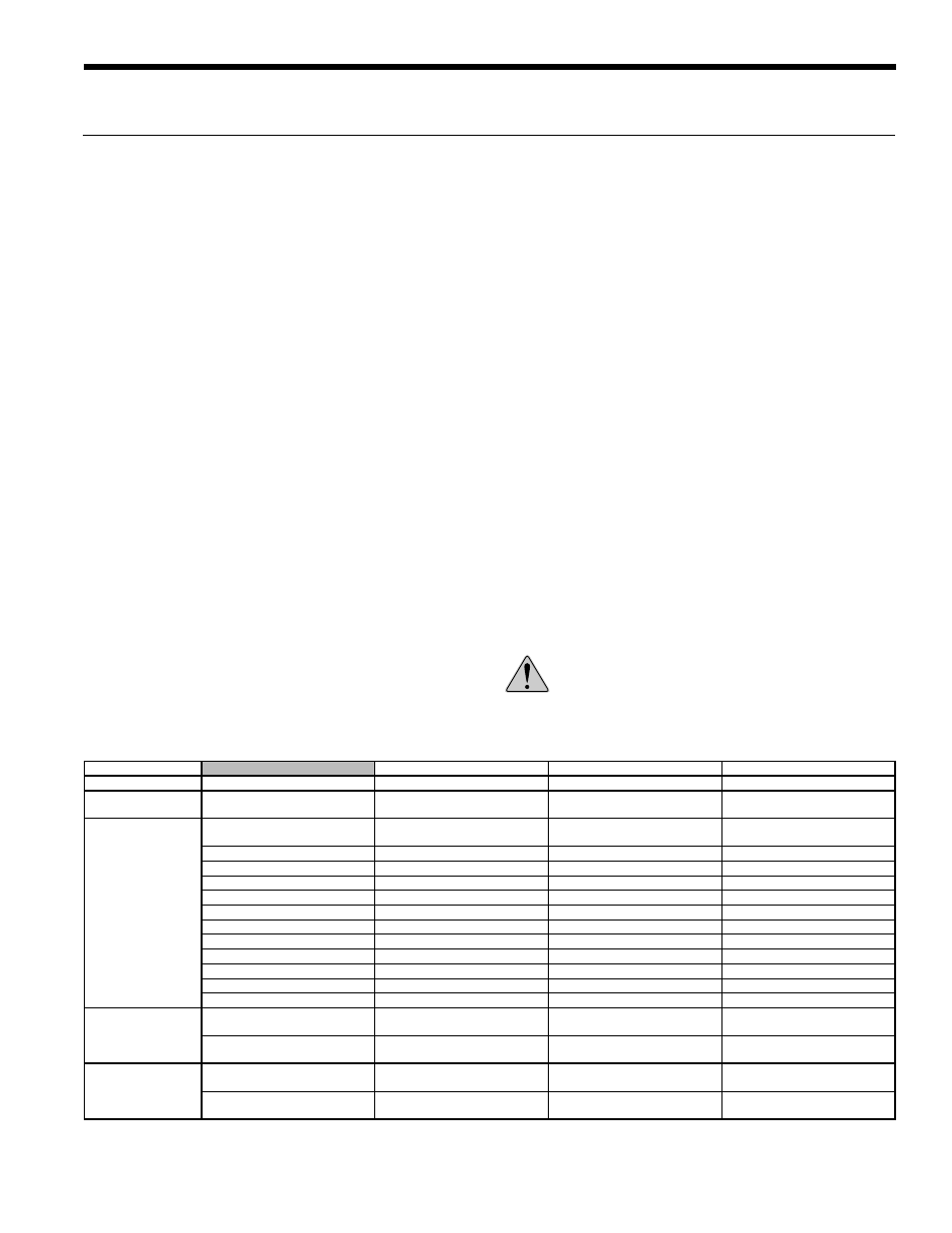

Material

Copper

90/10 Cupronickel

316 Stainless Steel

pH

Acidity/Alkalinity

7 - 9

7 - 9

7 - 9

Scaling

Calcium and

Magnesium Carbonate

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

(Total Hardness)

less than 350 ppm

Corrosion

Hydrogen Sulfide

Less than 0.5 ppm (rotten egg

smell appears at 0.5 ppm)

10 - 50 ppm

Less than 1 ppm

Sulfates

Less than 125 ppm

Less than 125 ppm

Less than 200 ppm

Chlorine

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Chlorides

Less than 20 ppm

Less than 125 ppm

Less than 300 ppm

Carbon Dioxide

Less than 50 ppm

10 - 50 ppm

10 - 50 ppm

Ammonia

Less than 2 ppm

Less than 2 ppm

Less than 20 ppm

Ammonia Chloride

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Ammonia Nitrate

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Ammonia Hydroxide

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Ammonia Sulfate

Less than 0.5 ppm

Less than 0.5 ppm

Less than 0.5 ppm

Total Dissolved Solids (TDS)

Less than 1000 ppm

1000 - 1500 ppm

1000 - 1500 ppm

LSI Index

+0.5 to -0.5

+0.5 to -0.5

+0.5 to -0.5

Iron Fouling

(Biological Growth)

Iron, FE

2

+ (Ferrous)

Bacterial Iron Potential

< 0.2 ppm

< 0.2 ppm

< 0.2 ppm

Iron Oxide

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Less than 1 ppm, above this

level deposition will occur

Erosion

Suspended Solids

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Less than 10 ppm and filtered

for max. of 600 micron size

Threshold Velocity

(Fresh Water)

< 6 ft/sec

< 6 ft/sec

< 6 ft/sec

NOTES: Grains = ppm divided by 17

mg/L is equivalent to ppm

2/22/12

Water Quality

The following table outlines the water quality guidelines

for unit heat exchangers. If these conditions are exceeded,

a secondary heat exchanger is required. Failure to supply

a secondary heat exchanger where needed will result in a

warranty exclusion for primary heat exchanger corrosion or

failure.

Strainers

These units must have properly sized strainers upstream of

both brazed plate heat exchangers to protect them against

particles in the fluid. Failure to install proper stainers and

perform regular service can result in serious damage to the

unit, and cause degraded performance, reduced operating

life and failed compressors. Improper installation of the unit

(which includes not having proper strainers to protect the

heat exchangers) can also result in voiding the warranty.

Field supplied strainers with 20-40 mesh (530-1060 microns)

are recommended, with 30 mesh (800 microns) being the

optimum choice. The strainers selected should have a mesh

open area of at least 6 square inches (39 square centimeters)

for each unit being serviced by the strainer. Using strainers

with a smaller amount of open area will result in the need for

more frequent cleaning.

Strainers should be selected on the basis of acceptable

pressure drop, and not on pipe diameter. The strainers

selected should have a pressure drop at the nominal flow rate

of the units; low enough to be within the pumping capacity of

the pump being used.

WARNING: Must have intermediate heat

exchanger when used in pool applications.

Water Quality Guidelines