Vortech Universal Big Block Carbureted System User Manual

Page 12

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

4

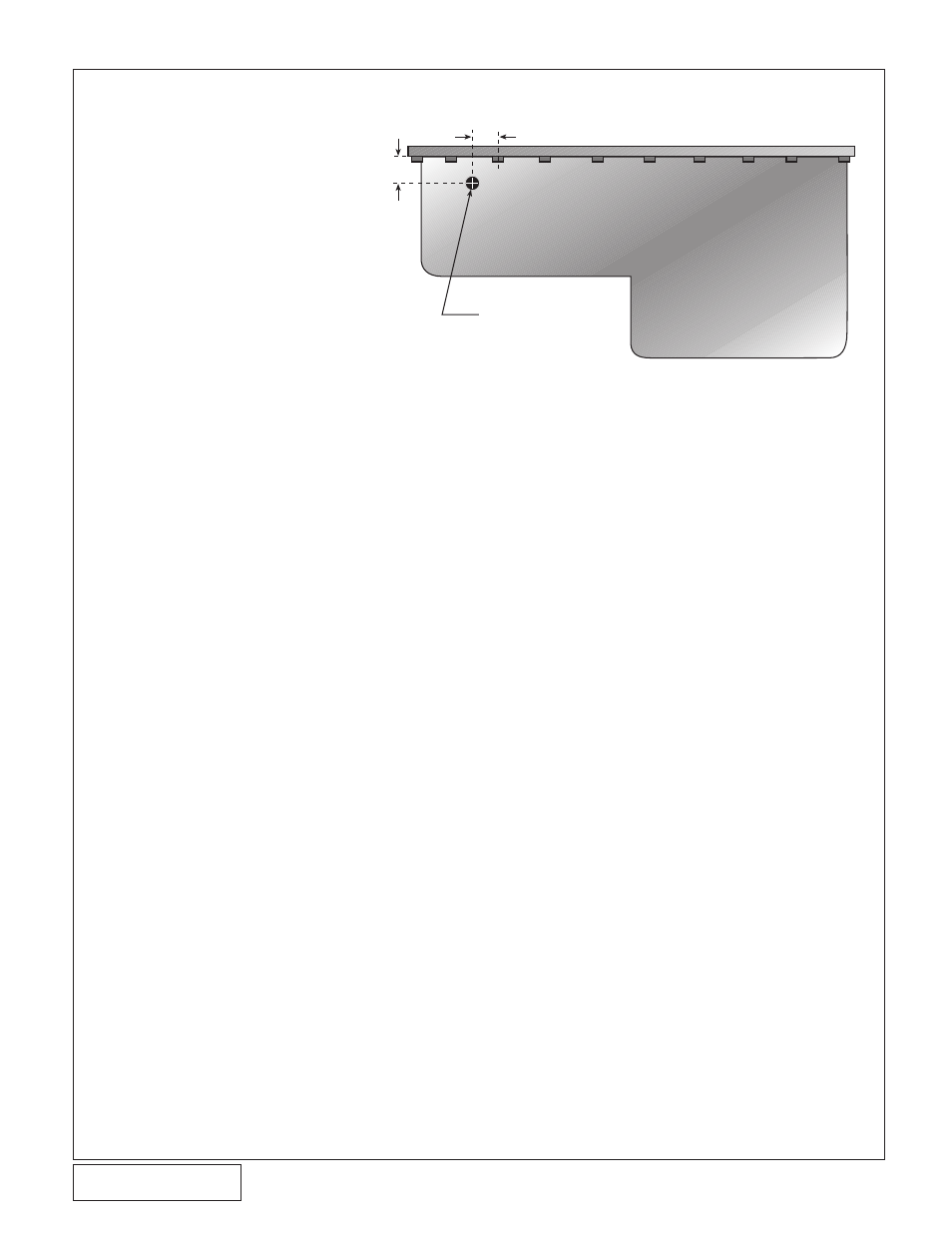

4. SUPERCHARGER OIl DRAIN

A. With this option, it is nec-

essary to make a hole in

the oil pan. (See Fig.

4-a.) It is best to punch the

hole rather than drill.

Remove paint from around

the hole area so that it

does not flake into the pan.

B. Make a mark on the oil

pan on the left side ahead

of the oil filter. The mark

should be 1" below the bolt

flange and forward of the

third bolt by 1". You may

choose a different place, if

necessary. However, take

care not to damage any

internal parts. The drain hose should gradual-

ly drop with no dips or kinks and should be

above the oil level.

C. Use a small center punch to perforate the

pan and expand the hole. Switch to a larger

diameter punch and expand the hole further

to approximately Ø9/16" (or use an air ham-

mer with a 9/16" round punch attachment).

Most punches are made from hexagon mate-

rial and may be placed in a socket with an

extension to make this procedure easier.

D. Tap the hole with a 3/8"NPT tap approximate-

ly 1/4" deep. Pack the flutes of the tap with

heavy grease to catch and hold the chips.

Once the tap is removed, it must be cleaned

and repacked before tapping resumes. Use a

small magnet to check for any stray chips in

the threads after completing the tapping pro-

cedure.

E.

Thoroughly clean the threaded area with ace-

tone or other solvent. Apply a small amount

of silicone sealer to the new threads. Apply a

small amount of silicone sealer to the threads

of the 3/8"NPT hose fitting and secure in the

hole. Make sure a seal is formed all around

the fitting. Allow the sealer to cure completely.

F.

Temporarily cover the end of the hose and

secure out of the way. The return is a gravity

drain and should be routed to provide a grad-

ual drop.

G. Drain and replace the engine oil and change

the filter.

1”

1”

PUNCH HOLE

THROUGH

Fig. 4-a