Spectrum Controls 1746sc-INI4vi User Manual

Page 44

40

SLC 500

™

Isolated Analog Input Modules

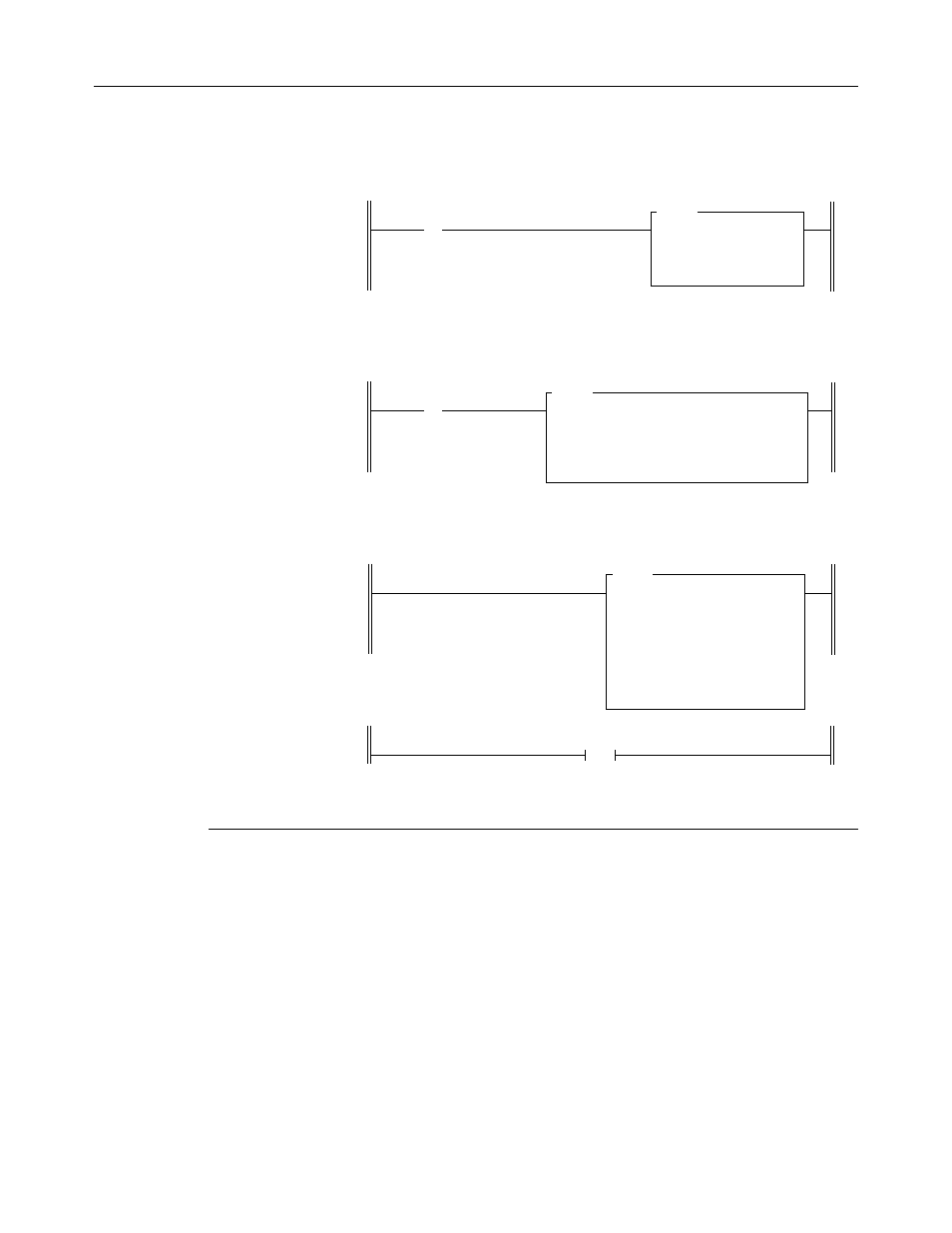

Figure 12. Programming for PID control example.

Rung 2:1

Channel 0 Status

I:3.4

] [

0

PID

PID

Control Block N11:0

Process Variable I:3.0

Control Variable N11:23

Control Block Length 23

Allocate N11:0 to N11: 22 for required Control Block file length of

23 words. The Process Variable is at I:3.0, which stores the value

of input data word 0 (channel 0). The output of the PID instruction

is at N11:23 (Control Variable address).

Rung 2:0

First Pass Bit

s:1

] [

15

MOV

MOVE

Source N10:0

Dest O:3.0

Initialize Module

Rung 2:2

SCL

SCALE

Source N11:23

Rate [/10000]

Offset

Dest

Set the Rate and Offset parameters for your application. The

Destination is typically an analog output channel. Refer to the

APS

User Manual or Analog I/O Modules User Manual for specific examples

of the SLC instruction.

END

Rung 2:3

Figure 13. Data table for PID control example.

address 15 data 0 address 15 data 0

N10:0 0000 0000 0001 1011

Important — When using your module’s Scaled For PID data format

with the SLC PID function, ensure that the Maximum Scaled S

max

(word7)

and Minimum Scaled S

min

(word 8) PID instruction parameters match

your module’s maximum and minimum scaled range in engineering units

for that channel. This allows you to accurately enter the setpoint in

engineering units.