PRW 18 PQ Signature Series Cummins Billet Steel Flexplate (SFI-Rated 29.3) User Manual

PRW For the car

PRW Industries, Inc.

1722 Illinois Avenue

Perris, California 92571

Tele: (951) 436-7900

Tech: (888) 377-9779

PQ

x

Platinum Series Flexplate Installation

Instructions

PARTS LIST

Item

Quantity

Flexplate

1 each

SFI 29.3 Certification Sticker

1 each

Drain plug replacement

(1/8” NPT x 5/16” L-SB & BB Ford only)

1 each

Step 1

Clean and inspect all parts (verify that the serial number on the sticker matches the SFI number engraved

on the flexplate).

Step 2

If not already completed, punch out the date on the SFI Decal and apply to the flexplate.

Step 3

Use a rubber mallet or block of wood and tap the flexplate into place onto the flange of the crankshaft.

Tap it evenly and flush upwards alongside the crankshaft flange. DO NOT draw the flexplate unto the

crank with bolts or impact wrench.

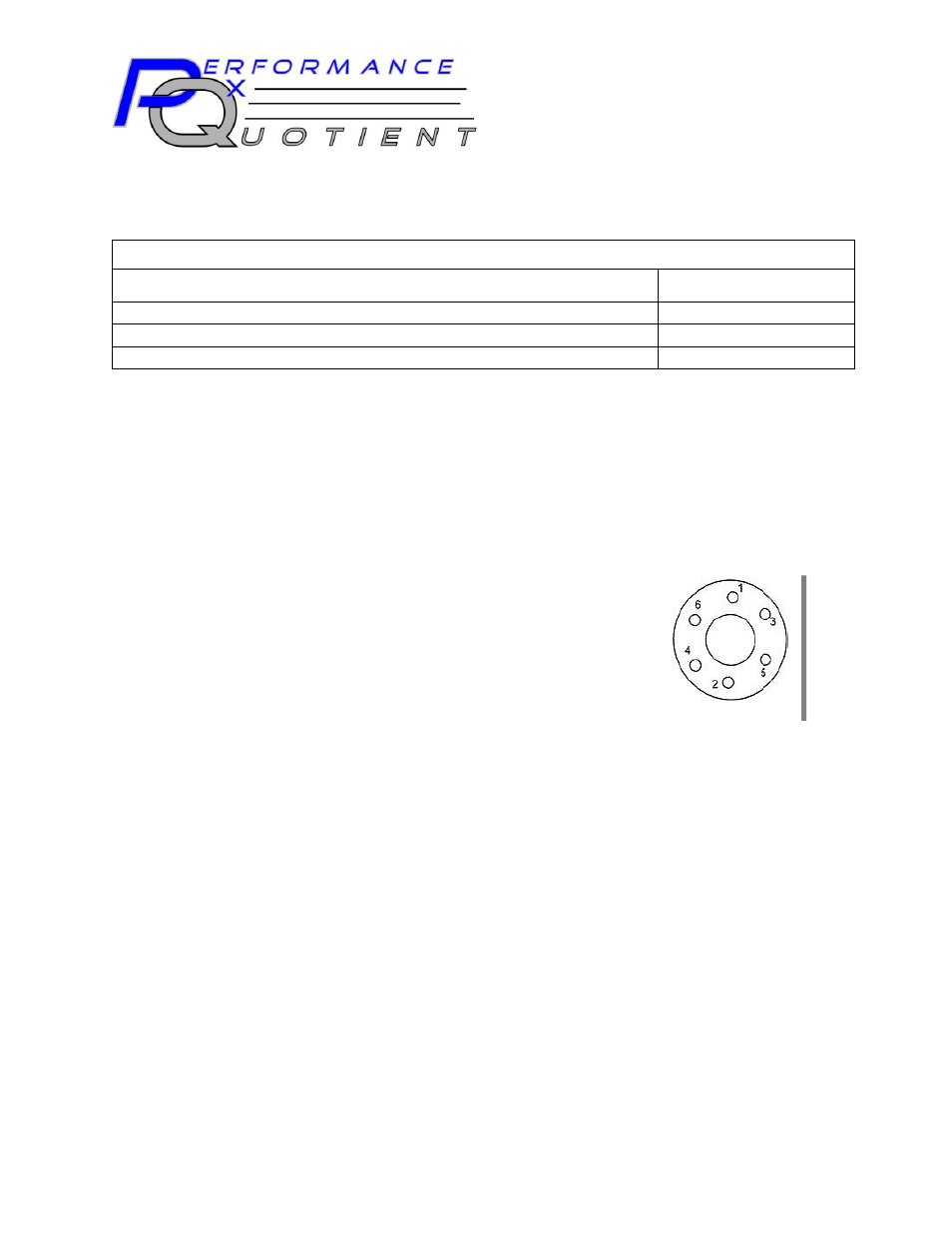

Step 4

After the flexplate has been placed onto the crankshaft, use PRW

threadlocker on the flexplate bolts and torque to OEM specifications.

To receive proper torque on the bolts, follow the torque pattern

below, use flat washers only.

Step 5

Hand turn the crankshaft to verify there is no wobble in the ring gear and to make sure it clears the

housing.

NOTES: 1) Welding weights on the flexplate for engine balancing is not recommended and voids

warranty; 2) drilling holes for balance is permissible, but not recommended; 3) high performance and

racing applications new flexplate bolts with a rating of 180,000 PSI or higher is recommended.

SPECIAL NOTE: Ford SB & BB

Stock Torque Converter – remove standard drain plug and replace with special Allen Head drain plug (PRW

PN 1800005) to preclude interference with flywheel. The use of a GM Converter may require a PRW Crank

Adapter #1800460 (PRW 18460xx Platinum Series) or #1800302 (PRW 18302xx Platinum Series).

Possible Causes for Damaged Flexplates

1. Not installing flexplate perpendicular to crankshaft flange

2. Engine or torque converter out of balance

3. Worn front pump bushing

4. Too much end play on the crank from excessive thrust bearing wear

5. Improper bolt torque and, or not in proper order according to OEM specs

6. A bad starter can wear or break off the teeth on the ring gear

7. Not properly shimming the starter, if needed, to align with the starter ring