Servicing and maintenance, 1 technical data, Cleaning – Glow-worm Xtrafast 96-120 User Manual

Page 7: Boiler casing

7

2000221595

To ensure the continued efficient and safe operation of the

appliance it is recommended that it is checked and serviced as

necessary at regular intervals. The frequency of servicing will

depend upon the particular installation conditions and usage,

but in general once a year should be enough.

If this appliance is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

Servicing/maintenance should be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

To obtain service, please call your installer or Heatcall (Glow-

worm’s own service organisation) using the telephone number

behind the controls cover door.

Please be advised that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning and servicing.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

boiler Logbook. You can check your installer is CORGI registered

by calling CORGI direct on: 01256 372300.

Servicing and Maintenance

Cleaning

WARNING: This appliance contains metal parts (components)

and care should be taken when handling and cleaning with

particular regard to edges of sheet metal parts to avoid any

possiblity of personal injury.

The boiler casing can be cleaned using a mild liquid detergent

with a damp cloth, followed by a dry cloth to polish.

Do not use any form of abrasive or solvent cleaner as you

may damage the paint work.

Boiler casing

CAUTION. Do not remove or adjust the casing in any way, as

incorrect fitting may result in faulty operation. If in doubt, consult

your installation/service company.

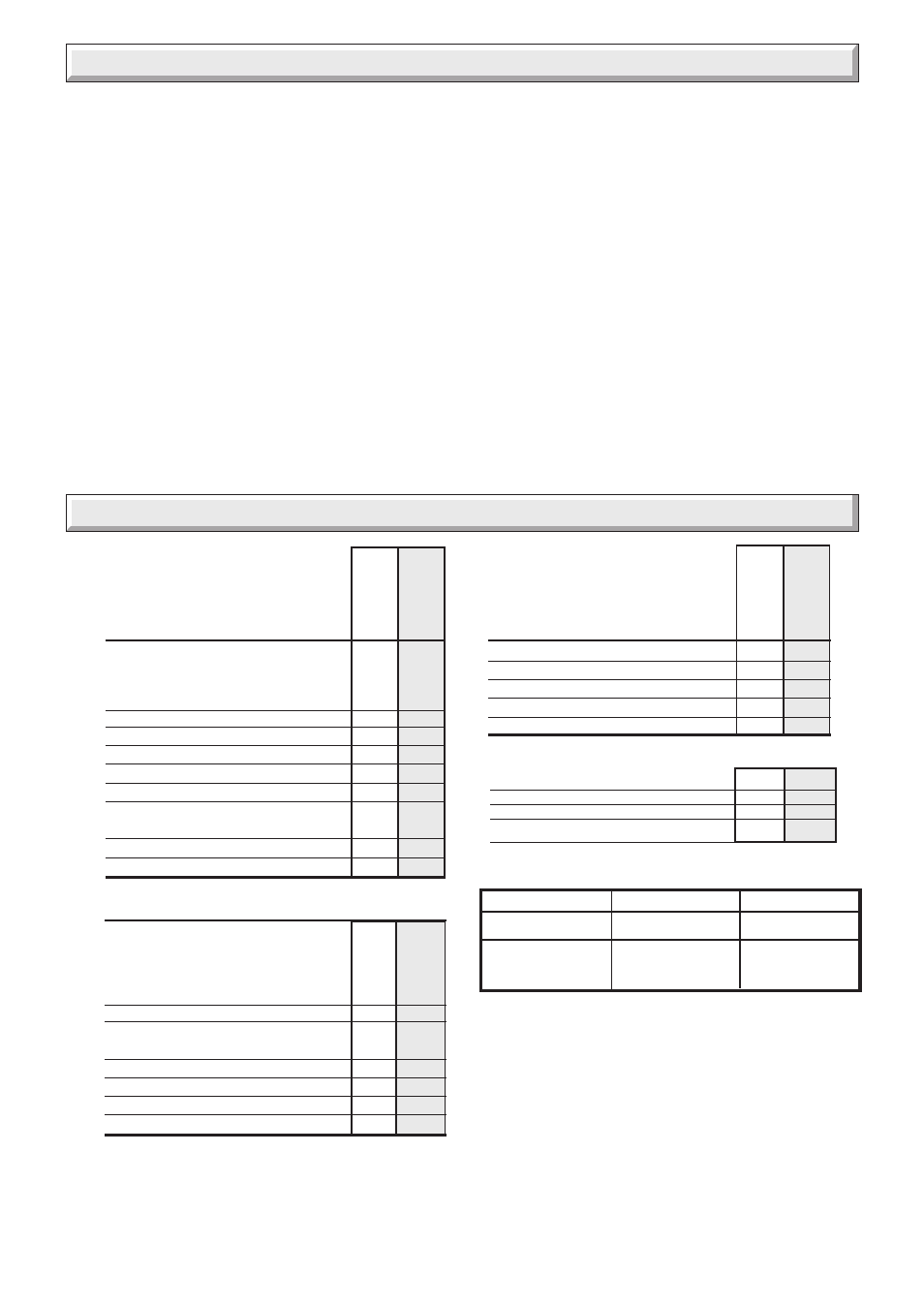

1 Technical Data

Heating output

ajustable from ... (kW)

10,4

11,7

to ... (kW)

27,6

34,6

from ... (BTU/H) 35,485 39,920

to ... (BTU/H) 94,170 118,053

Efficiency

(%)

**

**

Maximum heating temperature

(°C)

87

87

Expansion vessel effective capacity (l)

7

12

Expansion vessel charge pressure (bar)

0,5

0,5

Maximum system capacity at 75°C (l)

160

275

Safety valve,

maximum service pressure (bar)

3

3

Products outlet diameter

(mm)

60

60

Fresh air inlet diameter

(mm)

100

100

XTRAF

AST 96

XTRAF

AST 120

Ø Burner injector

(mm)

1,20

1,20

Inlet pressure

(mbar)

20

20

Burner pressure

(mbar)

13,8

14,1

Gas rate maximum

(m

3

/h)

3,20

3,98

Gas rate minimum

(m

3

/h)

1,32

1,48

Heating

Hot water output

automatically variable from ... (kW)

10,4

11,7

to ... (kW)

27,6

34,6

from ... (BTU/H) 35,485 39,920

to ... (BTU/H) 94,170 118,053

Maximum hot water temperature (°C)

60

60

Specific flow rate

(for 30°C temp rise)

(l/min.)

13,2

16,5

Threshold flow rate

(l/min.)

1

1

Nominal water flow rate

(l/min.)

11,3

16,5

Maximum supply pressure

(bar)

8

8

Minimum operating pressure

(bar)

0,7

0,7

Hot water

Electrical supply

(V)

230

230

Maximum absorbed power

(W)

220

220

Level of protection

IP44

IP44

Fuse rating

125mAT 125mAT

Natural Gas (G20)

XTRAF

AST 96

XTRAF

AST 120

Lift weight

51.2kg (112.9lb)

**.*kg (**.**lb)

Total weight

(inclusive water)

**.*kg (**.**lb)

**.*kg (**.**lb)

Xtrafast 96

Xtrafast 120

The Seasonal Efficiency Domestic Boilers UK (SEDBUK) is

**.*%.

The value is used in the UK Government's Standard

Assesssment Procedure (SAP) for energy rating of dwellings.

The test data from which it has been calculated have been

certified by B.S.I.