09 ff, 17 fault finding – Glow-worm Xtrafast 96-120 User Manual

Page 26

26

2000221595

17 Fault Finding

Fault finding must be carried out by a competent person.

WARNING. Always isolate the boiler from the electrical supply

before carrying out any electrical replacement work.

On completion of a fault finding task that has required the

disconnection and making of electrical connections then check

for earth continuity, polarity and resistance to earth must be

carried out.

If any gas-carrying components are disturbed, removed or

replaced it will be necessary on completion to check for gas

soundness with leak detection fluid.

Before trying to operate the boiler make sure that :

• All gas supply cocks are open and that the gas supply has

been purged of air.

• There is a permanent mains supply to the boiler.

• The heating system pressure is at least 1 bar.

• The fuse on the PCB is intact.

Preliminary electrical system checks, as outlined in a multimeter

instruction book, are the first checks to be carried out during a

fault finding procedure.

Should there be any doubt about the voltage supply to any of

the components, it is possible to carry out a simple electrical

test to ensure all is operational in that area.

To carry out the electrical test, gain access to the main Printed

Circuit Board (PCB) , and measure the voltages according to

table 2.

Table 2

Voltage

Measured value

Measuring point

230 Volt

230 V AC

Between terminals H8.1 and H8.2

24 Volt

maximum 33V DC

Between terminals B2.4 and B2.7

minimum 20V DC

15 Volt

15V

+ 0.5V

Between terminals B2.4 and B2.2

Display

5V

+ 0.5V

Between terminals B2.4 and B4.2

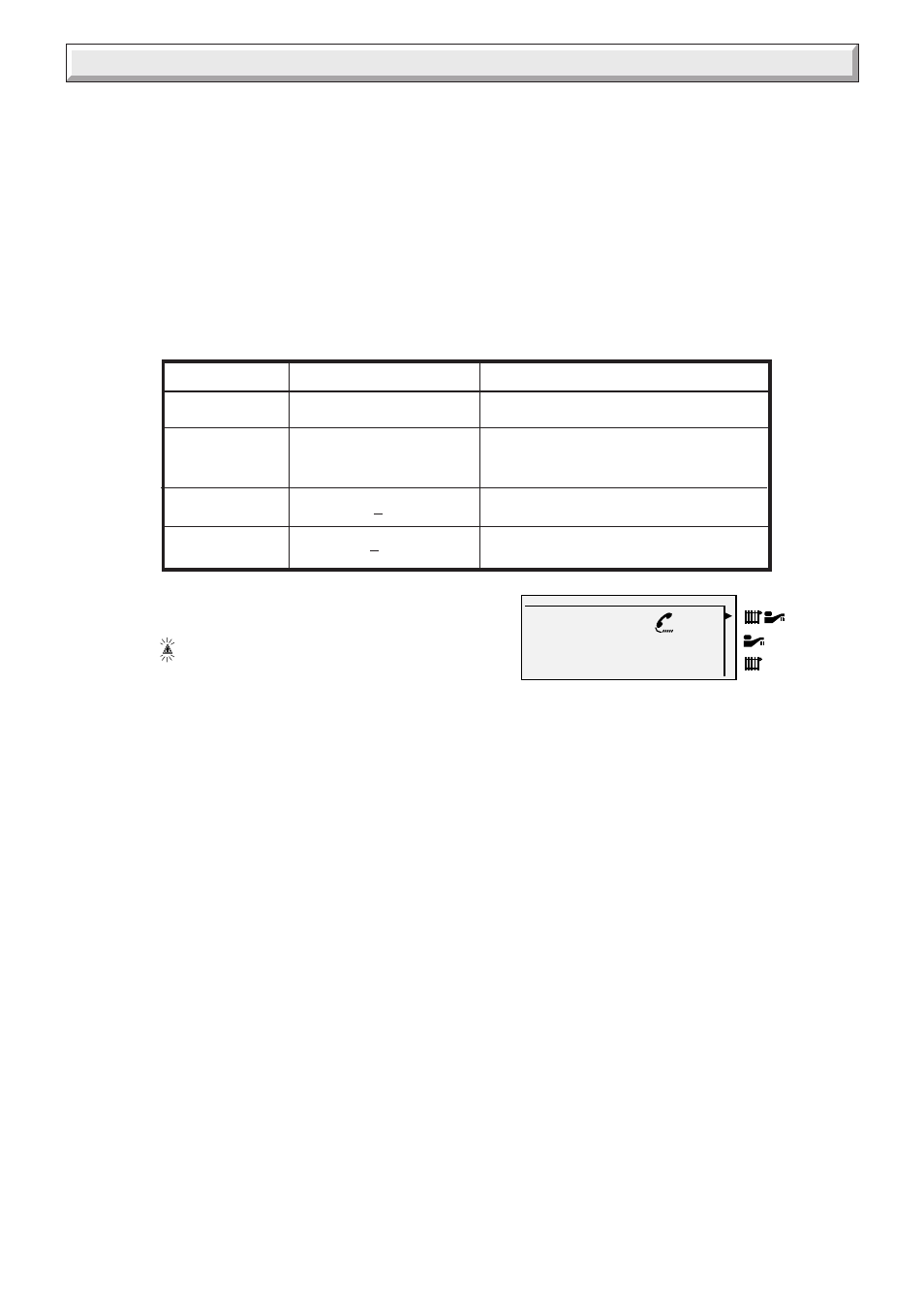

09

FF

Sec 052

A fault code is displayed on the left hand side of the LCD display, whilst at the same time, the letters appear with a

telephone symbol.

Thermistor values

The following table applies to the central heating,

domestic hot water and storage vessel thermistors:

Temperature (

°

C)

Resistance (

Ω

)

0 ...................................... 32565

5 ...................................... 25345

10 ..................................... 19875

15 ..................................... 15700

20 ..................................... 12500

25 ..................................... 10000

30 ...................................... 8060

35 ...................................... 6535

40 ...................................... 5330

45 ...................................... 4370

50 ...................................... 3605

55 ...................................... 2989

60 ...................................... 2490

65 ...................................... 2085

70 ...................................... 1755

75 ...................................... 1480

80 ...................................... 1260

85 ...................................... 1070

90 ....................................... 920

95 ....................................... 785

100 ...................................... 680

System pressure sensor

The resistance of the sensor at various pressures is

as follows :

0 bar ...................... between 280

Ω

and 320

Ω

1 bar ...................... between 195

Ω

and 220

Ω

3 bar ...................... between 93

Ω

and 143

Ω

The In-board fault diagnostic system. Should a fault

occur on the boiler, the warning LED at the top of the

user display

will illuminate and the LCD display will

indicate the precise area where the fault has occurred.