Glow-worm Xtrafast 96-120 User Manual

Page 10

10

2000221595

A B

C

D E

2

3

6

4

7

5

8

9

1

12

14

13

15

16

18

17

19

20

22

21

23

11

25

24

10

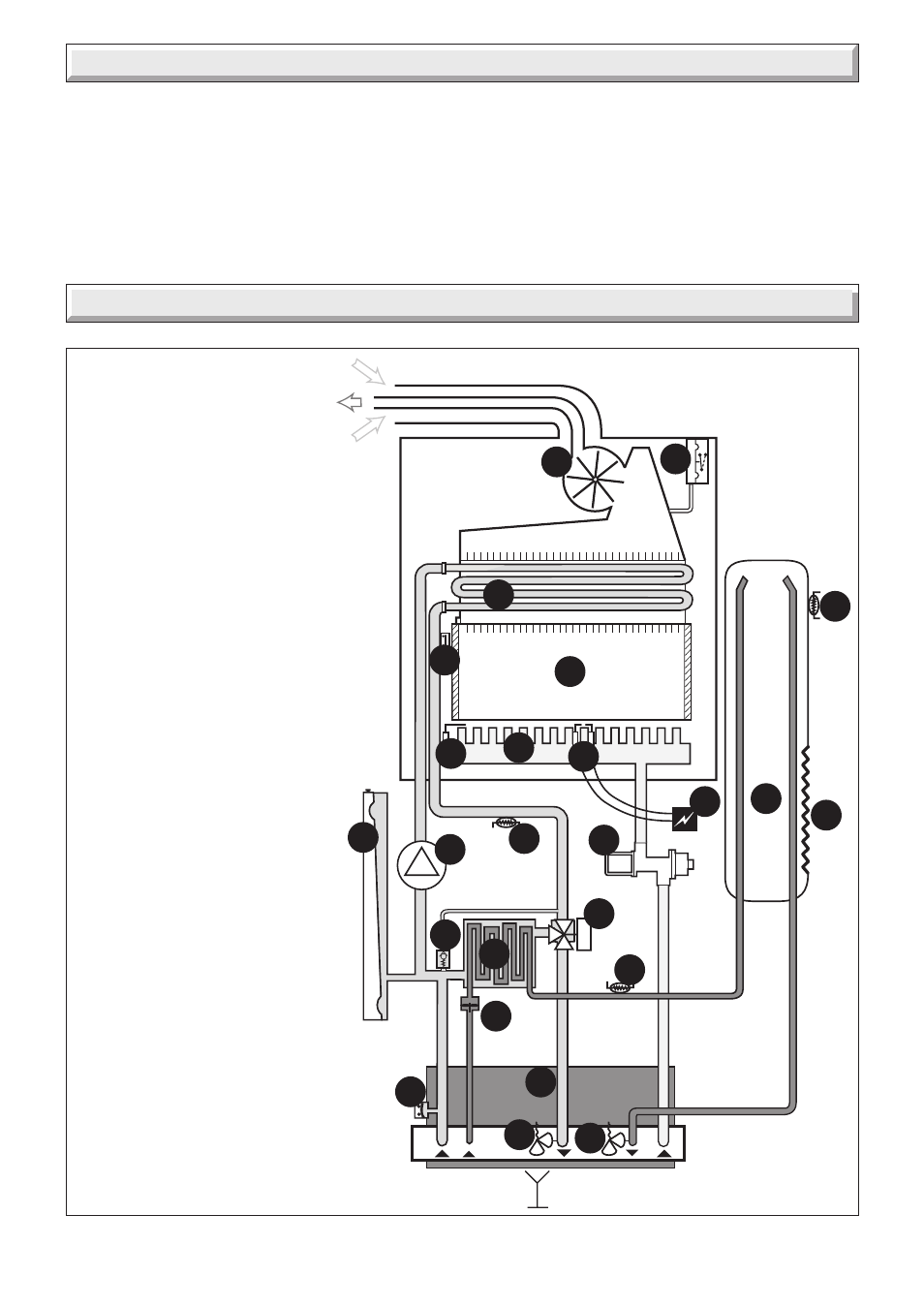

Diagram 5.1

4 Domestic Hot Water System Design

• Copper tubing or plastic hep

2

o may be used for the domestic

hot water system. Unnecessary pressure losses should be

avoided.

• A flow restrictor limiting the flow through the boiler to a

maximum of 12 l/min is fitted to the boiler.

• The boiler will operate with a minimum supply pressure of 0,7

bar, but under reduced flow rate. Best operating comfort will be

obtained from a supply pressure of 1 bar.

'Hard Water Areas'

In areas where the water is 'hard', more than 200mg/litre, it is

recommended that a proprietary scale reducer is fitted in the

cold water supply to the boiler.

1 - Domestic thermistor

2 - Three way valve

3 - Gas valve

4 - Ignition module

5 - Heating element

6 - Micro accumulation vessel

7 - Burner

8 - Ignition electrode

9 - Combustion chamber

10 - Micro accumulation vessel thermistor

11 - Main heat exchanger

12 - Air pressure switch

13 - Heating safety valve (3 bar)

14 - Electronic control (PCB)

15 - Domestic water flow sensor

16 - Bypass

17 - Domestic heat exchanger

18 - Pump

19 - Expansion vessel

20 - Heating thermistor

21 - Overheat safety thermostat

22 - Flame sense electrode

23 - Fan

24 - Domestic safety valve (10 bar)

25 - Loss of water sensor

A - Heating return

B - Cold water inlet

C - Heating flow

D - Domestic hot water outlet

E - Gas

10026

5 Boiler Schematic