8 piping system installation – Glow-worm Xtrafast 96-120 User Manual

Page 13

13

2000221595

Sch 173a

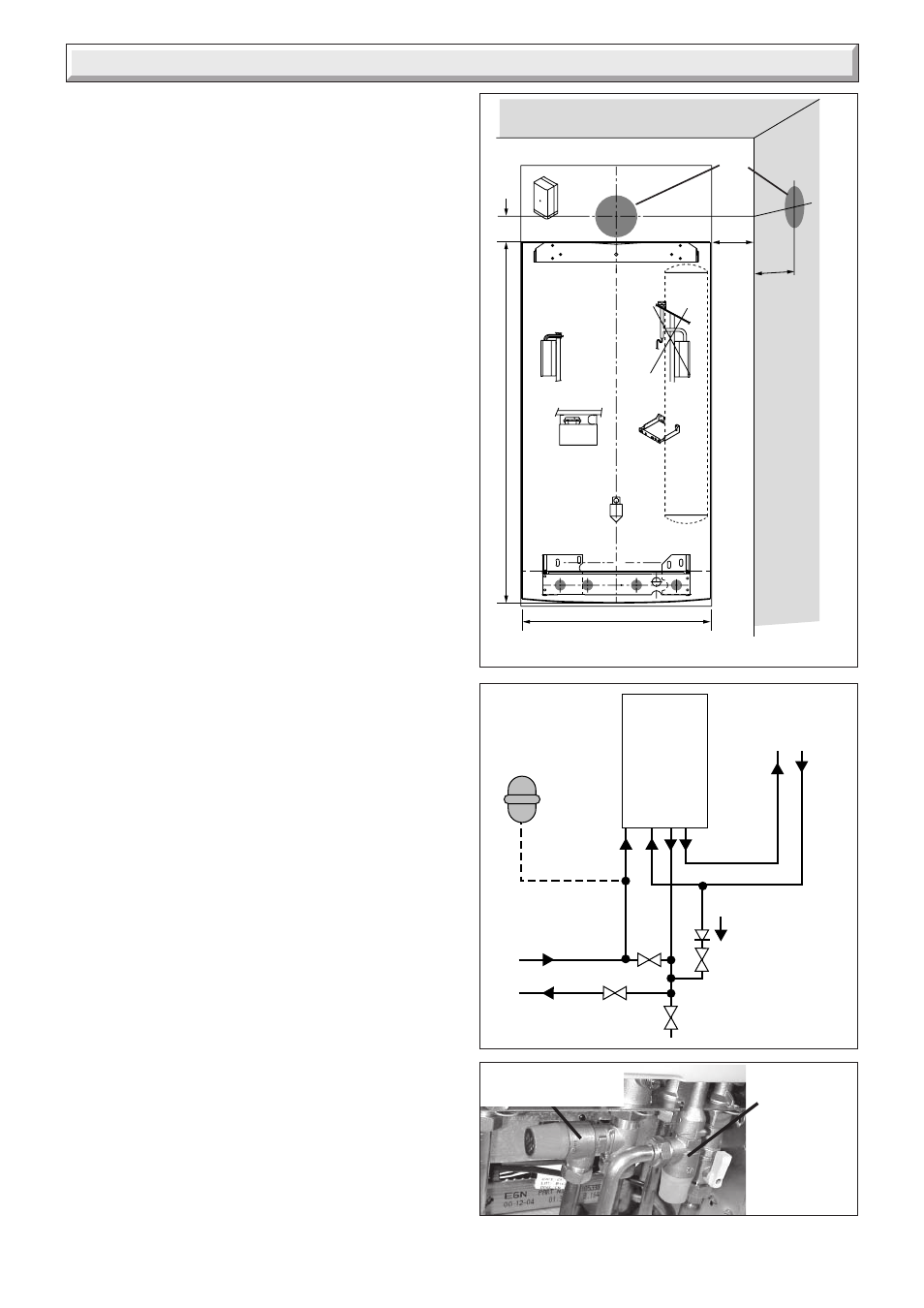

Diagram 8.2

Flow

control valve

Drain point

Filling device

Bypass

valve

Domestic

water

Heating

circuit

Return

Additional

expansion

vessel

(if required)

Boiler

Hot

Cold supply

9684

Diagram 8.1

105

234

20

65

890

470 (96)

552 (120)

8.5 Cutting the flue hole

• Making allowance for the slope of the flue, cut hole in external

wall, preferably using a core drill. For installations with internal

and external access use a 105 mm diameter core drill.

For installations with internal access only use a 125 mm

diameter core drill.

8.6 Important

When cutting the flue hole and when extending the flue centre

line to a side wall, remember that the flue system must have a

fall of about 35 mm per metre of flue DOWNWARD towards the

terminal. There must NEVER be a downward incline towards

the boiler.

8.6 Terminal position

The minimum acceptable spacings from the terminal to

obstructions and ventilation openings are shown in diagram

6.1.

The boiler must be installed so that the terminal is exposed to

the external air.

Should any doubt exist as to the permissible position of the

terminal, contact the Glow-worm Technical Helpline 01773

828100.

8.7 Water connection

Connect the system pipework to the copper connections on the

fixing jig observing the correct flow and return format as shown

in diagram 8.2. Do not subject the isolating valves to heat.

8.8 Heating safety valve and domestic safety

valve discharge, refer to diagram 8.3.

Tee the domestic safety valve outlet pipe to the heating safety

valve outlet pipe and extend horizontally to the outside wall.

WARNING. It must not discharge above an entrance or window

or any type of public access area.

Connect the safety valve discharge pipe to the outlets of both

the heating safety valve and the domestic water safety valve,

the discharge must be extended using not less than 15mm.

pipe, to discharge in a visible position outside the building,

facing downward preferably over a drain.

The pipe must have a continuous fall and be routed to a position

so that any discharge of water, possibly boiling or steam, cannot

create any danger to persons, damage to property or external

electrical components and wiring. Tighten all pipe connection

joints.

8.9 Gas connection

• The supply from the governed gas meter must be of adequate

size to provide a constant inlet working pressure of 20 mbar (8

in w.g.).

To avoid low gas pressure problems, it is recommended that the

gas supply is connected using 22 mm pipe.

• On completion, the gas installation must be tested using the

pressure drop method and purged in accordance with the

current issue of BS6891.

8.10 Gas Safety (Installation and use)

Regulations

In your interests and that of gas safety, it is the law that ALL gas

appliances are installed and serviced by a competent person in

accordance with the above regulations.

8 Piping System Installation

Diagram 8.3

DOMESTIC

SAFETY

VALVE

(10bar)

HEATING SAFETY

VALVE 3 bar)