Installation – Glow-worm Ultracom2 sxi User Manual

Page 27

0020092785_02 - 05/10 - Glow-worm

- 25 -

i

Due to the modulating operation of the boiler and the

need to check the gas inlet pressure and measure

the gas rate at maximum rate, it will be necessary to

force it to maximum.

• Activate the test mode "P.01" and set the value to 100 in

order to force the burner at P. max. See chapter "Specific

adjustment ► Appliance technical settings and parameter list

► Test modes".

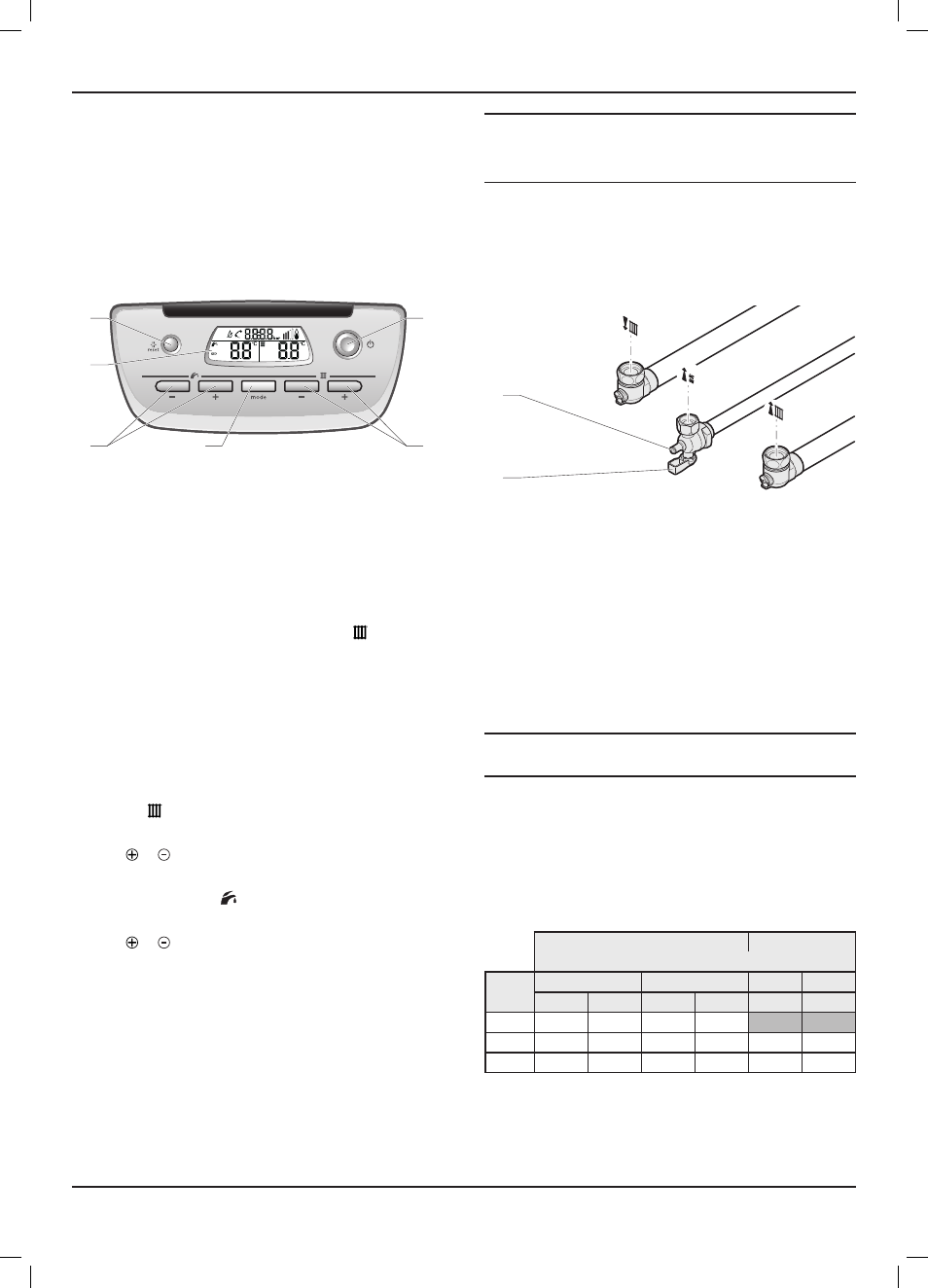

12.5.1

Operational Gas Inlet Pressure

1

2

Key

1 Gas service isolation valve

2 Test point

• With all other gas appliances operating, check the operational

supply pressure at the gas service isolation valve test point.

The nominal supply pressure for Natural Gas (G20) is 20mbar.

The nominal supply pressure for LPG (G31) is 37mbar.

• Turn the taps and appliances off, then disconnect the

pressure gauge.

Additionally the safe nominal maximum heat input of the

appliance can be achieved at an inlet pressure down to 15mbar.

i

The burner pressure cannot be measured and is not

used to measure the gas rate.

12.5.2

Gas Rate

• Make sure that all other gas burning appliances and pilot

lights are off.

• Check the gas rate using the gas meter test dial and stop

watch, at least 10 minutes after the burner has lit, see table

below for approximate rates.

Gas rates (G20)

Gas rates (G31)

(approx) after 10 mins from cold

Model

MIN

MAX

MIN

MAX

m

3

/h

ft

3

/h

m

3

/h

ft

3

/h

kg/h

kg/h

12sxi

0.43

15.3

1.3

45.9

18sxi

0.54

19.1

2.7

95.3

0.4

1.98

30sxi

0.92

32.5

3.77

133.1

0.67

2.77

In communal or LPG installations where the gas rate cannot be

measured it is acceptable to measure the combustion rate as

described in the servicing section.

• On completion, press the "reset" button to reset the boiler.

• Check the integrity of the appliance combustion circuit and

relevant seals.

• Check that all internal/external controls are calling for heat.

• Check that the gas service isolation is open.

• To adapt the appliance to another type of gas, see chapter

"LPG conversion".

12.4.2

Adjusting the temperature

3

2

1

6

4

5

Key

1 Domestic hot water temperature control buttons

2 Display

3 Reset button

4 On/Off button

5 Central heating temperature control button

6 Mode selection button

• Light the appliance by following the procedure below.

• Select the "Heating" function by pressing the “Mode” button

repeatedly to scroll through your options until is shown.

The appliance will enter a self checking routine, then the fan

will start and the ignition sequence commence. The boiler, if

necessary, will automatically repeat the ignition sequence a

further 4 times.

If the burner fails to ignite “F28” will be displayed, initially, this

may be due to air in the gas supply line. Press the reset button.

Do not use the reset button to purge the installation - never

press reset more than 3 times.

• Press the central heating water temperature button and

the factory setting temperature will be displayed.

• Press or buttons to adjust.

• If Glow-worm intelligent controls are fitted, press the

hot water temperature button and the factory setting

temperature will be displayed.

• Press or buttons to adjust.

12.5 Gas rates

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

• On completion, test the gas installation for tightness using

the pressure drop method and suitable leak detection fluid,

purge in accordance with the above standard.

INSTALLATION