Installation – Glow-worm Ultracom2 sxi User Manual

Page 15

0020092785_02 - 05/10 - Glow-worm

- 13 -

7.4.2

boiler hanging

a

With regards to the Manual Handling Operations,

1992 Regulations, the following lift operation

exceeds the recommended weight for a one

person lift, refer to chapter "Manual Handling".

2

1

Key

1 boiler

2 Hanging bracket

• Lifting the boiler into position, lean the top of the boiler

slightly to the wall and position just above the hanging

bracket.

• Lower the boiler slowly and engage onto the hanging bracket

8 Hydraulic connection

8.1

Gas and water connections

The whole of the gas installation, including the meter, should

be inspected, tested for tightness and purged in accordance

with the current issue of BS6891 and in IE the current edition of

I.S.813 “Domestic Gas Installations”.

i

The appliance may contain a small amount of water,

place a water container beneath the boiler connections.

• Take care to clean the pipes before assembly removing any

debris or burrs. Grease and oils may need to be removed

they are not possible to remove by cleansing and flushing.

Foreign bodies in the system may enter the appliance and

interrupt its operation.

• Do not use any solvent products, due to the risk of damaging

the circuit.

a

Do not perform any 'hot work' directly under

the appliance, this may cause damage to the

appliance base. Heat may also damage the

isolation valves.

Always pre-assemble pipes before fitting them to

the boiler.

• Only use original seals supplied with the appliance.

• Check that there are no leaks. Repair if necessary.

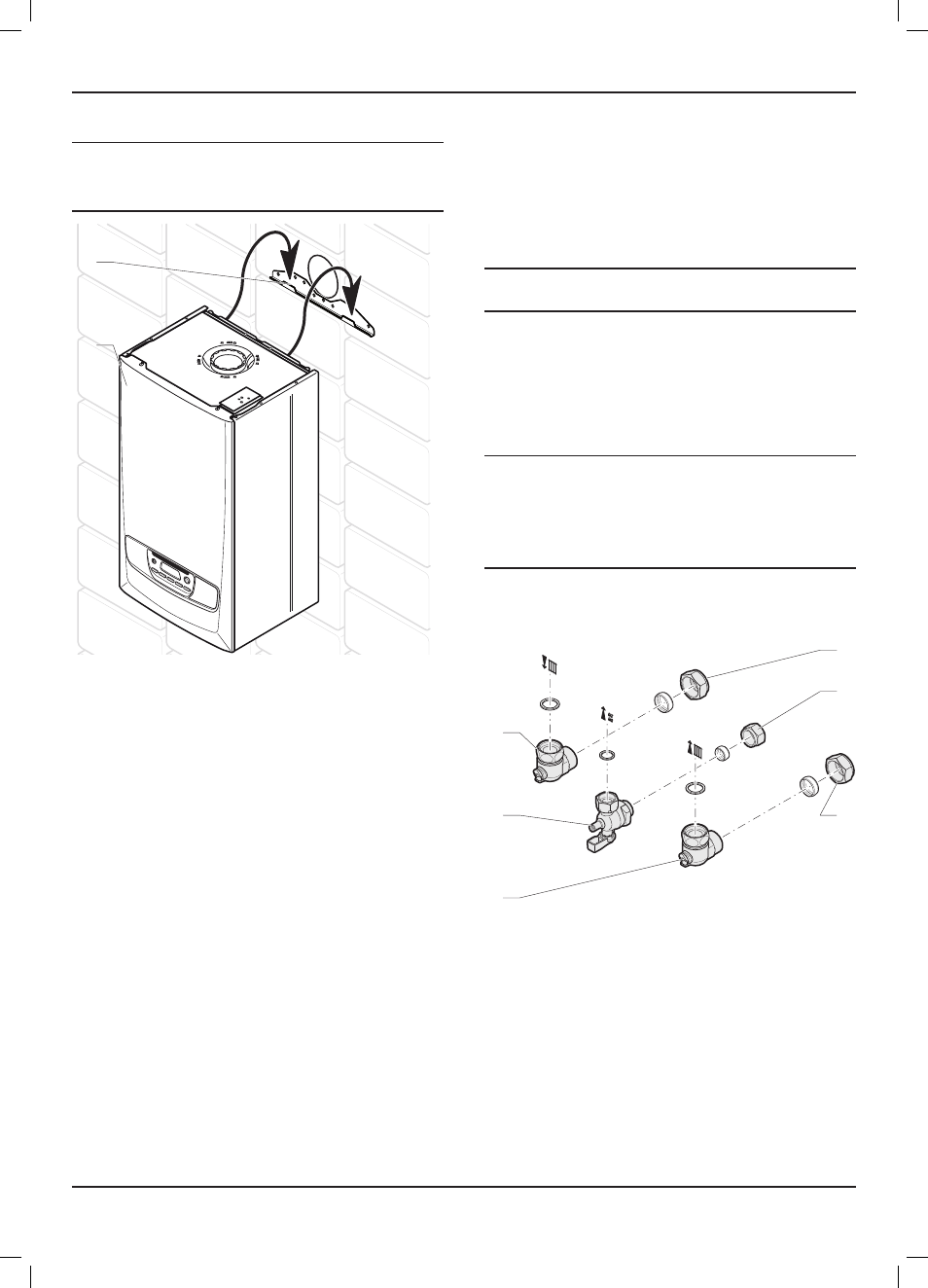

1

2

3

4

5

4

Key

1 Heating return isolating valve + sealing washer ¾"

2 Gas service isolating valve with pressure test point + sealing

washer ½"

3 Heating flow isolating valve + sealing washer ¾"

4 Connection Ø O.D. 22 mm

5 Connection Ø O.D. 15 mm

• Remove the protective caps from the boiler connections.

• Flush out the domestic hot water and the heating systems.

INSTALLATION