1 general, 9 drain, 10 safety valve – Glow-worm Ultimate 100FF User Manual

Page 8: 11 location, 12 boiler clearances, 13 room ventilation, 14 boilers in a compartment, 15 timber frame building, 16 heating system controls

8

221966B

It is recommended that plastic pipes for primary pipework

should not be used for this boiler.

1.9 Drain

System

A draining tap must be provided at the lowest points of the

system which will allow the entire system, boiler and hot water

cylinder to be drained.

Draining taps should be to the current issue of BS2879.

Boiler

A draining point is fitted at the bottom right hand side of the heat

exchanger.

Cover controls to avoid water damage.

If required remove the combustion chamber front cover to

improve access.

1.10 Safety Valve

A safety valve need not be fitted to an open vented system.

1.11 Location

This boiler is not suitable for outdoor installation.

This boiler is suitable for installation in bathroom zones 2 and 3.

The boiler may be installed in any room, although particular

attention is drawn to the requirements of BS7671 with respect

to the installation of a boiler in a room containing a bath or

shower. Any electrical switch should be so positioned that it

cannot be touched by a person using the bath or shower. The

electrical provisions of the Building Standards (Scotland)

Regulations apply to such installations in Scotland.

In GB this is the current I.E.E. WIRING REGULATIONS and

BUILDING REGULATIONS.

In IE reference should be made to the current edition of I.S.813

"Domestic Gas Installations" and the current ETCI rules.

The boiler must be mounted on a flat wall which is sufficiently

robust to take its total weight.

The boiler may be fitted to a wall made of combustible material.

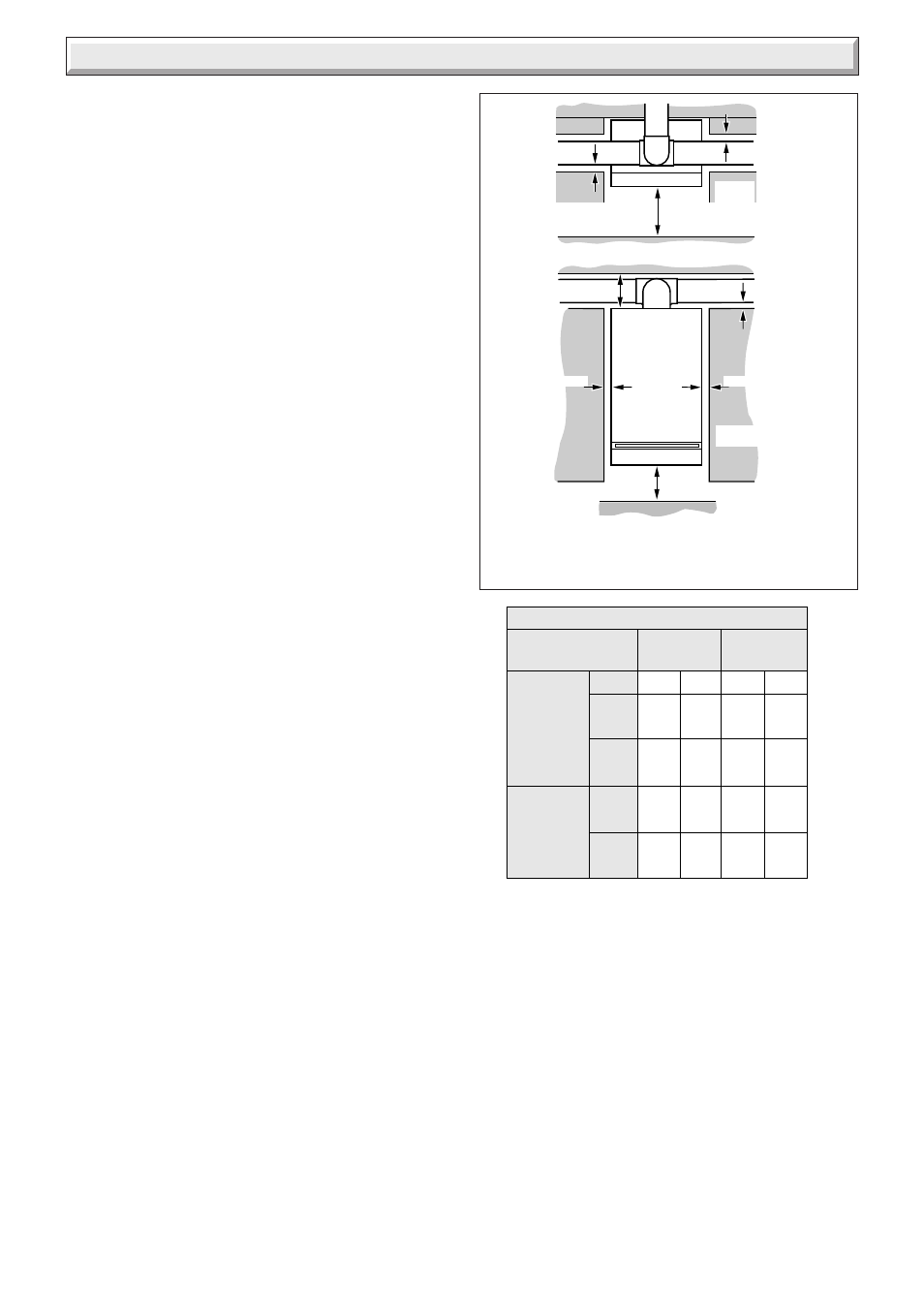

1.12 Boiler Clearances

Refer to diagram 1.2.

The boiler must be positioned so that at least the minimum

operational and servicing clearances are provided.

Additional clearances may be required for installation.

If fixtures are positioned next to the boiler they should be made

removable for access to pipework.

Sufficient clearance must be left in front of the boiler for

servicing.

1.13 Room Ventilation

The boiler is room sealed and does not require the room or

space containing it to have permanent airvents.

1.14 Boilers in a Compartment

Where the installation of the boiler will be in an unusual position,

special requirements are needed, the current issue of BS6798

gives detailed guidance on these requirements.

A compartment used to enclose the boiler must be designed

and constructed specifically for this purpose. An existing

cupboard or compartment modified for the purpose may be

used. Details of essential requirements for cupboard or

compartment design are given in the current issue of BS6798.

The doorway opening should be of sufficient size to allow for

easy removal of the boiler.

Where the boiler is fitted in a cupboard or compartment,

permanent high and low level ventilation must be provided. The

minimum ventilation areas are given in Table 3.

1.15 Timber Frame Building

If the boiler is to be installed in a timber frame building it should

be fitted in accordance with the Institute of Gas Engineers

document IGE/UP/7/1998. If in doubt seek advice from the local

gas undertaking or Glow-worm.

1.16 Heating System Controls

The heating system should have installed: a programmer and

room thermostat controlling the boiler.

Thermostatic radiator valves may be installed, however they

must not be fitted in a room where the room thermostat is

located.

NOTE: For further information, see the current issue of the

Building Regulations, approved document L1, and the

references:

1) GIL 59, 2000: Central heating system specification (CheSS)

and

2) GPG 302, 2001: Controls for domestic central heating

system and hot water. BRECSU.

0208M

6mm

6mm

65mm

6mm

6mm

6mm

160mm

500mm

Additional clearances may be

required for installation

FRONT

VIEW

MINIMUM CLEARANCES FROM WALLS CEILING,

FLOOR, CUPBOARD, WORKTOPS, AND

INFLAMMABLE MATERIALS

PLAN

VIEW

TABLE 3. COMPARTMENT AIR VENTS

VENTILATION

REQUIREMENTS

VENTILATION

FROM

ROOM

OR SPACE

MODEL

VENTILATION

FROM

OUTSIDE

100FF

HIGH LEVEL

VENT AREA

LOW LEVEL

VENT AREA

100FF

330

51

330

51

396

61.5

396

61.5

cm

2

in

2

cm

2

in

2

120FF

120FF

165

25.5

165

25.5

198

30.5

198

30.5

0209M

Diagram 1.2

1 General