Glow-worm Ultimate 100FF User Manual

Page 24

24

221966B

Instruct and demonstrate the safe and efficient operation of the

boiler, heating system and domestic hot water system.

Advise the user, that to ensure the continued efficient and safe

operation of the boiler it is recommended that it is checked and

serviced at regular intervals. The frequency of servicing will

depend upon the particular installation and usage, but in general

once a year should be enough.

Draw attention, if applicable, to the current issue of the Gas

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance in the UK.

REMEMBER: When replacing a part on this appliance, use only

spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Glow-worm

NOTES:. To ensure the continued efficient and safe operation

of the boiler it is recommended that it is checked and serviced

as necessary at regular intervals. The frequency of servicing

will depend upon the particular installation conditions and

usage, but in general once a year should be enough.

It is the Law that any servicing is carried out by a competent

person.

Before servicing turn off the gas and isolate the electrical supply

to the boiler.

After completing a service always test for gas soundness and

carry out functional check on controls.

Unless stated otherwise all parts are replaced in the reverse

order to removal.

10.1 Access

Refer to diagram 8.6 and slide controls cover forward and off.

Remove the outer case, see diagram 8.5.

NOTE: As an aid to servicing the air pressure switch tube

connections can be used to obtain a products of combustion

reading.

Remove the RED tube from the connection on the air pressure

switch and insert the analyser probe into the tube.

Switch on the electrical supply to operate the fan and turn on the

gas supply.

On completion of the test switch off the electrical supply and the

gas supply and reconnect the red tube to the air pressure

switch.

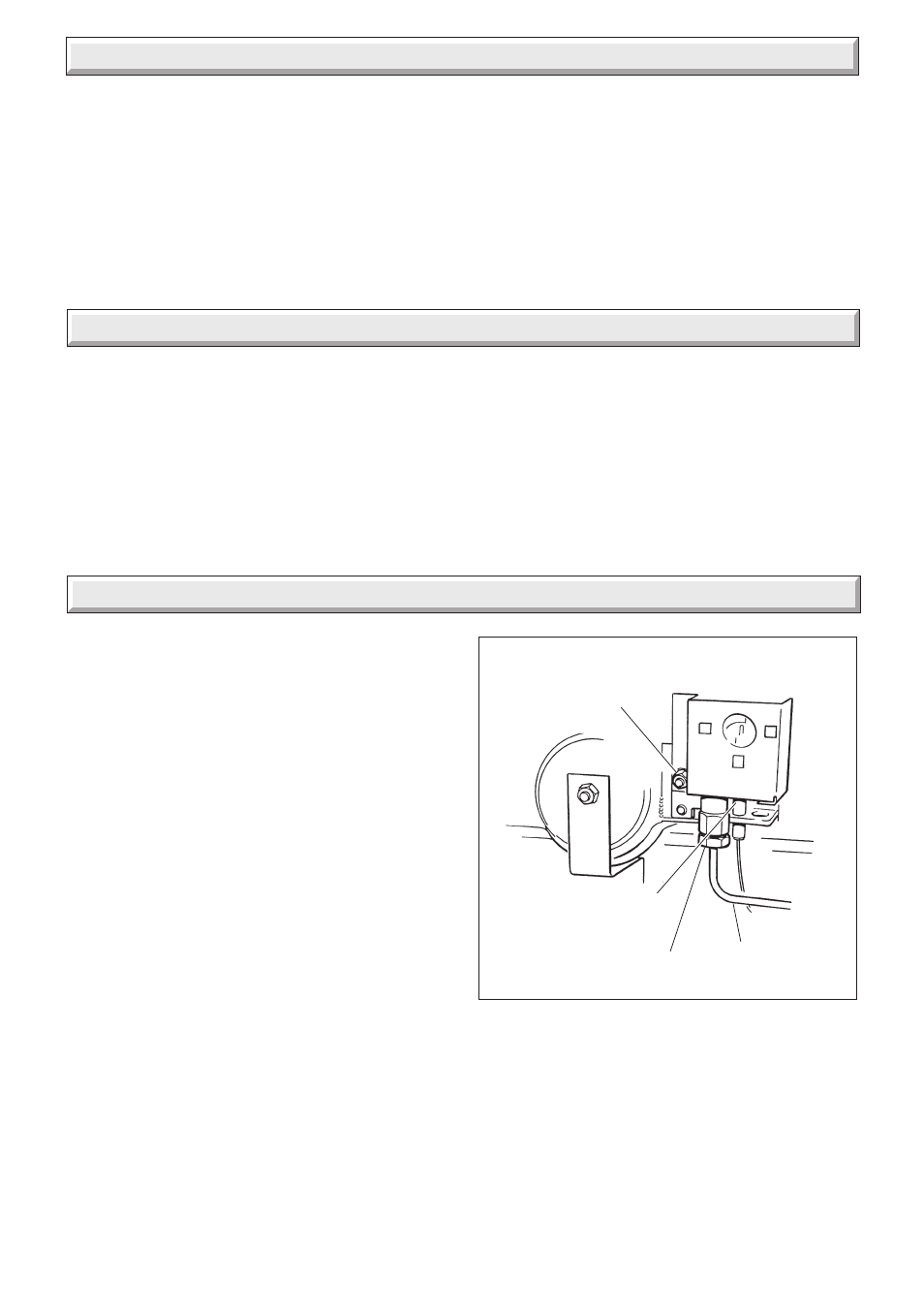

Diagram 10.1

SECURING NUT AND

SHAKEPROOF

WASHER

PILOT PIPE

UNION

CONNECTOR

ELECTRODE AND

LEAD ASSEMBLY

4094

8.10 Operational Checks and Completion

Adjust the control thermostat and any system controls to their

required settings.

Do not attempt to adjust the thermostat calibration screw.

Operate the boiler again on full service and check that the

balancing is satisfactory, making adjustments as necessary.

Fit the front cover by hooking it under at the top and securing

with the screws previously removed, see diagram 8.5.

Fit the controls cover by hooking into the sliders and pushing it

back as far as it will go, see diagram 8.6.

8 Commissioning

9 Instructions to the User

10 Servicing

Testing Flue Gases: If any doubt exists that the flue products

are not exhausting correctly, investigate by use of a gas

analyser (FGA).

8.11 Protection against Freezing

If the boiler is to be out of use for a period of time during severe

weather conditions we recommended that the whole of the

system, including the boiler, be drained off to avoid the risk of

freezing up.

It is the Law that servicing is carried out by a competent

person.

Advise the user of the precautions necessary to prevent damage

to the system and the building in the event of the heating system

being out of use during frost and freezing conditions.

Reminder, leave these instructions and the ‘Benchmark’ logbook

with the user.

For IE, it is necessary to complete a "Declaration of Conformity"

to indicate compliance to I.S.813. An example of this is given in

the current edition of I.S.813.