8 commissioning – Glow-worm Ultimate 100FF User Manual

Page 21

21

221966B

Please ensure the "Benchmark" logbook is completed and left

with the user.

8.1 All Systems

Commissioning should be carried out by a competent person

in accordance with the current issue of BS6798.

Do not operate the boiler wthout water.

Make sure that the system has been thoroughly flushed out with

cold water without the pump in place.

Refit the pump, fill the system with water, making sure that all

the air is properly vented from the system and pump.

Before operating the boiler check that all external controls are

calling for heat.

8.2 Sealed Water Systems Only

Flush the whole system with cold water without the pump in

place. Refit the pump and fill until the pressure gauge registers

2.7bar (40lbf/in2). Clear any air locks and check for water

soundness.

Check the operation of the safety valve, by allowing the water

pressure to rise until the valve opens. The valve should open

within +/-0.3bar (+/-4.3lbf/in

2

) of the preset pressure. Where

this is not possible conduct a manual check and test.

Release cold water to initial system design pressure.

The set pointer on the pressure gauge should be set to coincide

with the indicating pointer.

8.3 Initial Lighting and Testing

CAUTION: This work must be carried out by a competent

person, in accordance with the current issue of BS6798.

Make sure that all naked lights and cigarettes are out.

Identify the controls by reference to diagram 8.1.

Check that the boiler is isolated from the electrical supply.

Make sure that the control thermostat is turned to “O” the “Off”

position.

Turn boiler gas service cock “On”.

Test the pilot supply tube and its connection for gas soundness

as follows:

Disconnect the ignition lead from the PCB, see diagram 7.2.

Remove the combustion chamber front, see diagram 8.2.

WARNING: The fan operates on mains voltage, terminals will

become live.

Turn the electrical supply on and check that all remote controls

are calling for heat.

Check that the pump is circulating water through the system.

To complete the test it is necessary to operate the boiler without

its case, but UNDER ALL OTHER CIRCUMSTANCES the

case must be correctly fitted and sealed.

Turn the control thermostat knob fully clockwise and the fan will

work.

NOTE: There will be no sparks at the pilot. Take care and light

the pilot with a match.

Test the pilot supply and connections for gas soundness, using

a suitable leak detection fluid.

Very cold weather may delay the operating sequence.

The pilot rate is preset and must not be adjusted.

The step adjustment screw must not be touched.

The pilot flame length should be as shown in diagram 8.3.

Turn the control thermostat knob to “O” and isolate the boiler

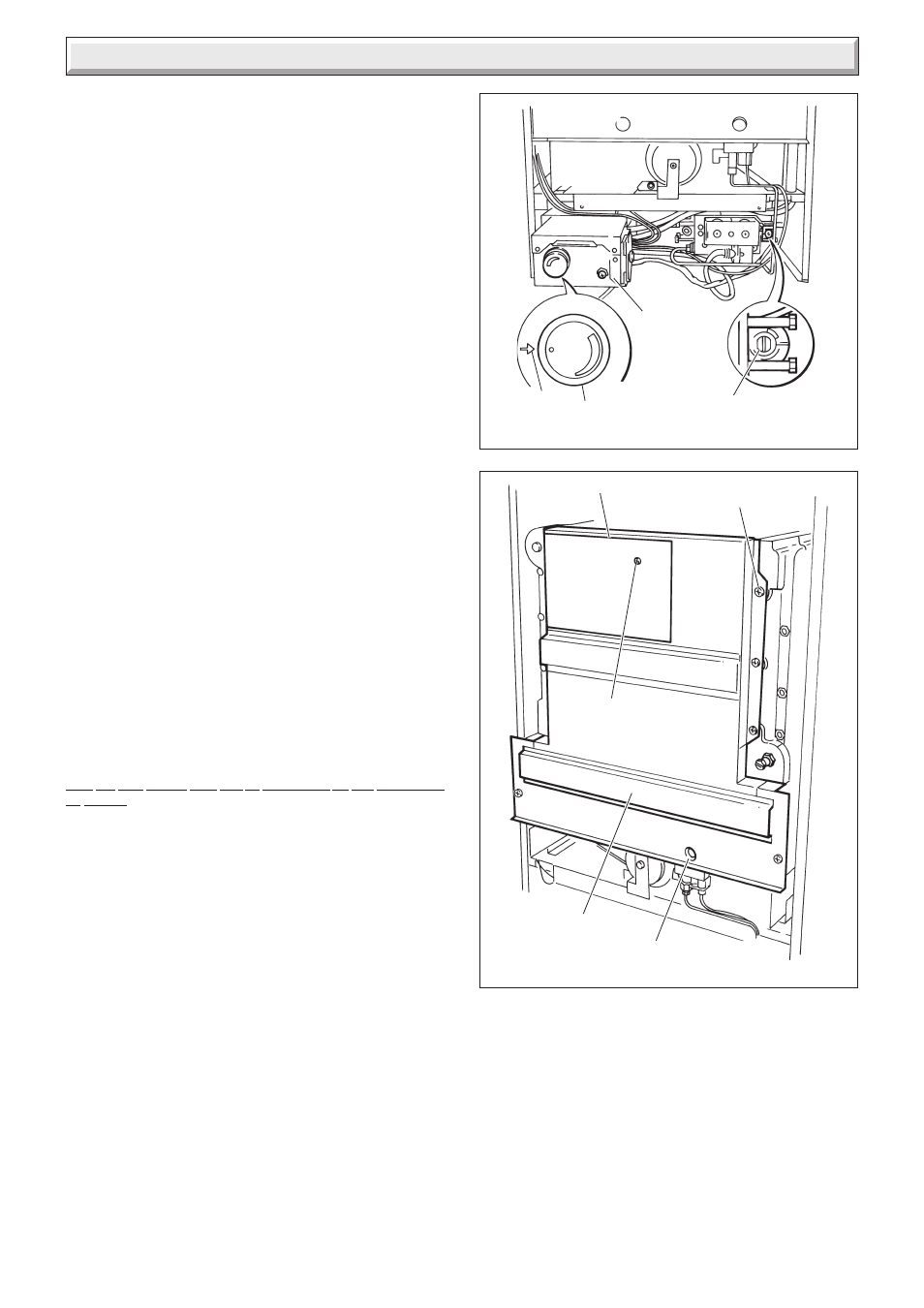

Diagram 8.1

GAS SERVICE COCK

(SHOWN OFF)

Diagram 8.2

SETTING

POINT

OVERHEAT

SAFETY

CUT-OFF

CONTROL

THERMOSTAT

COMBUSTION

CHAMBER

FRONT PANEL

VIEWING

WINDOW

SECURING

SCREW

CLEANING PLATE

SECURING

SCREW (8)

4291

4292

8 Commissioning

from the electrical supply.

Fit the combustion chamber front.

Reconnect the ignition lead to the PCB.

For future reference, stick the self adhesive arrow indicator to

the data label, against the rating that the boiler is going to be set

to. The arrow is in the loose items pack.

Loosen the main burner pressure test point screw and connect

a suitable pressure gauge, see diagram 8.4.

Make sure that any remote controls are calling for heat.

Switch on/connect the electrical supply to the boiler and heating

system, neon 1 will light.