8 servicing – Glow-worm Hideaway 80CF User Manual

Page 15

15

221756A

8 Servicing

Servicing must be carried out by a competent person.

Before starting any servicing, turn off the gas and electrical

supply to the boiler.

Always test for gas soundness after completing any servicing

or replacement of gas carrying components.

8.1 Gain Access to Boiler

Pull door forwards at the top to disengage studs and lift to

release from the slots, see diagram 7.3.

Lift the plinth front up and forwards to withdraw, see diagram

7.3.

If the top casing is removed, care must be taken not to damage

or lose any plastic pegs when refitting, see Section 5.3.

8.2 Boiler Flueways

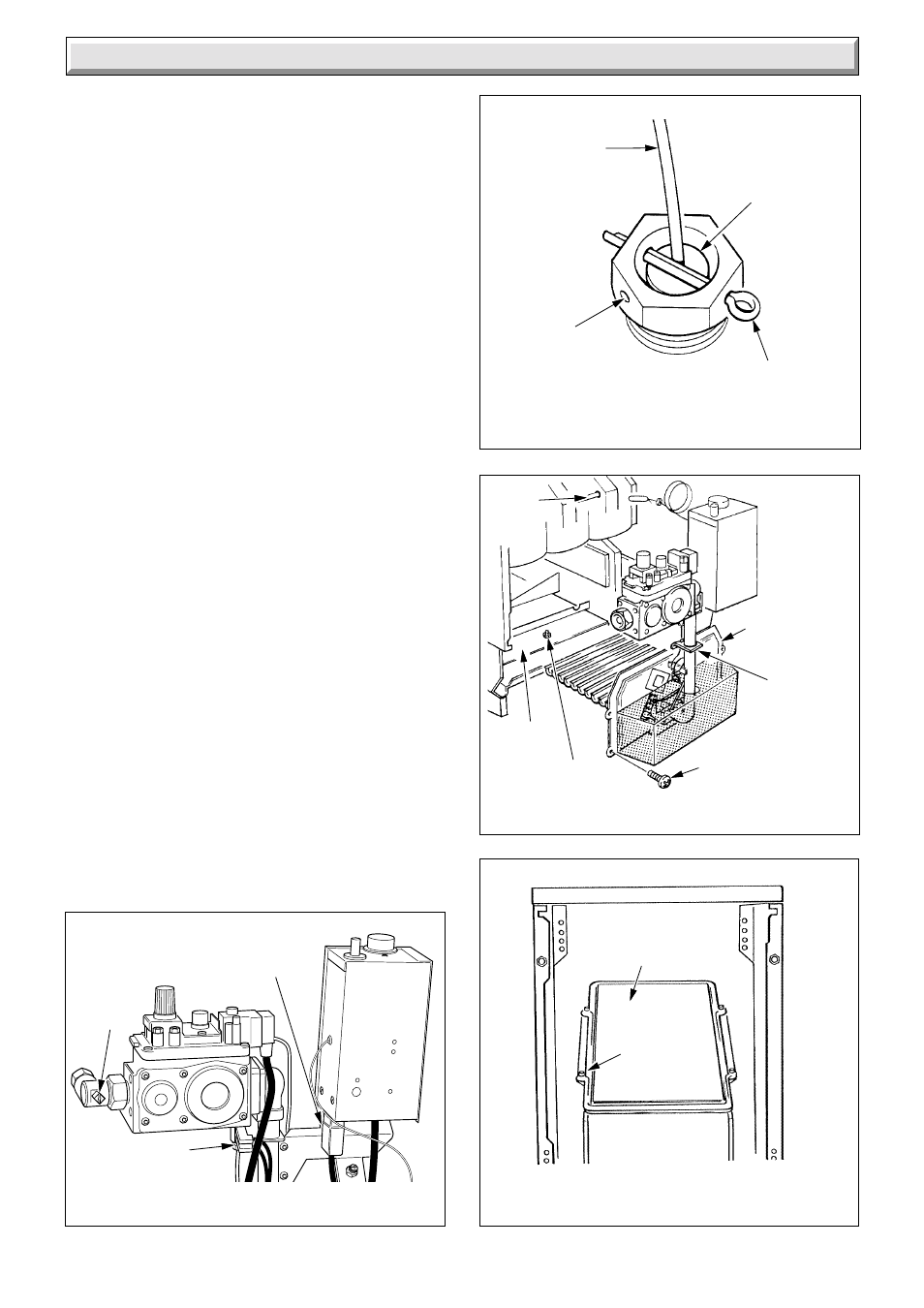

Unscrew the union nut securing the gas service cock to the gas

valve, see diagram 8.1.

Remove the mains inlet connector by pulling downwards, see

diagram 8.1.

Remove electrical connections from the interupter, see diagram

8.1.

Remove the retaining split pin from the phial pocket then

withdraw the phial and capillary, see diagram 8.2.

Remove the four screws retaining the combustion chamber

cover and burner assembly, see diagram 8.3.

Ease the gas service cock away from the gas valve and unhook

the pipe support bracket from the tie bar to enable the assembly

of cover, control box, gas valve and burner to be withdrawn

forward.

Remove graphite coated nuts to release baffle tray, remove

from combustion chamber taking care not to damage the

insulation material.

Remove self-tapping screws which retain the flueway cleaning

door and lift door clear, see diagram 8.4.

Remove flueway baffles, see diagram 8.7.

Place a sheet of paper in the combustion chamber to catch any

flue debris.

Access for flueway cleaning is made through the flueway

cleaning and combustion chamber openings.

Thoroughly clean boiler flueways and fins from the top and

bottom with a suitable stiff brush. Remove any debris from the

base of the combustion chamber.

Check that the flueways are clear, view with the aid of a mirror

or reflector.

ACCESS TO FLUEWAY

Diagram 8.4

0908

FLUEWAY

CLEANING

DOOR

SELF-

TAPPING

SCREW (4)

Diagram 8.2

SECURING THE

THERMOSTAT PHIAL

1870

LOCATION

WASHER

PHIAL

POCKET

RETAINING

SPLIT PIN

THERMOSTAT

CAPILLARY

ACCESS FOR SERVICING

Diagram 8.3

7993

SECURING

SCREW (4)

GRAPHITE

COATED NUT

BAFFLE

TRAY

COMBUSTION

CHAMBER

COVER

PIPE

SUPPORT

BRACKET

TIE

BAR

Diagram 8.1

ISOLATION OF

GAS AND ELECTRICITY

7992

MAINS INLET

CONNECTOR

(pull downwards)

GAS

SERVICE

COCK

(turn off)

(shown

closed)

ELECTRICAL

CONNECTIONS