4 installation – Glow-worm Hideaway 80CF User Manual

Page 10

10

221756A

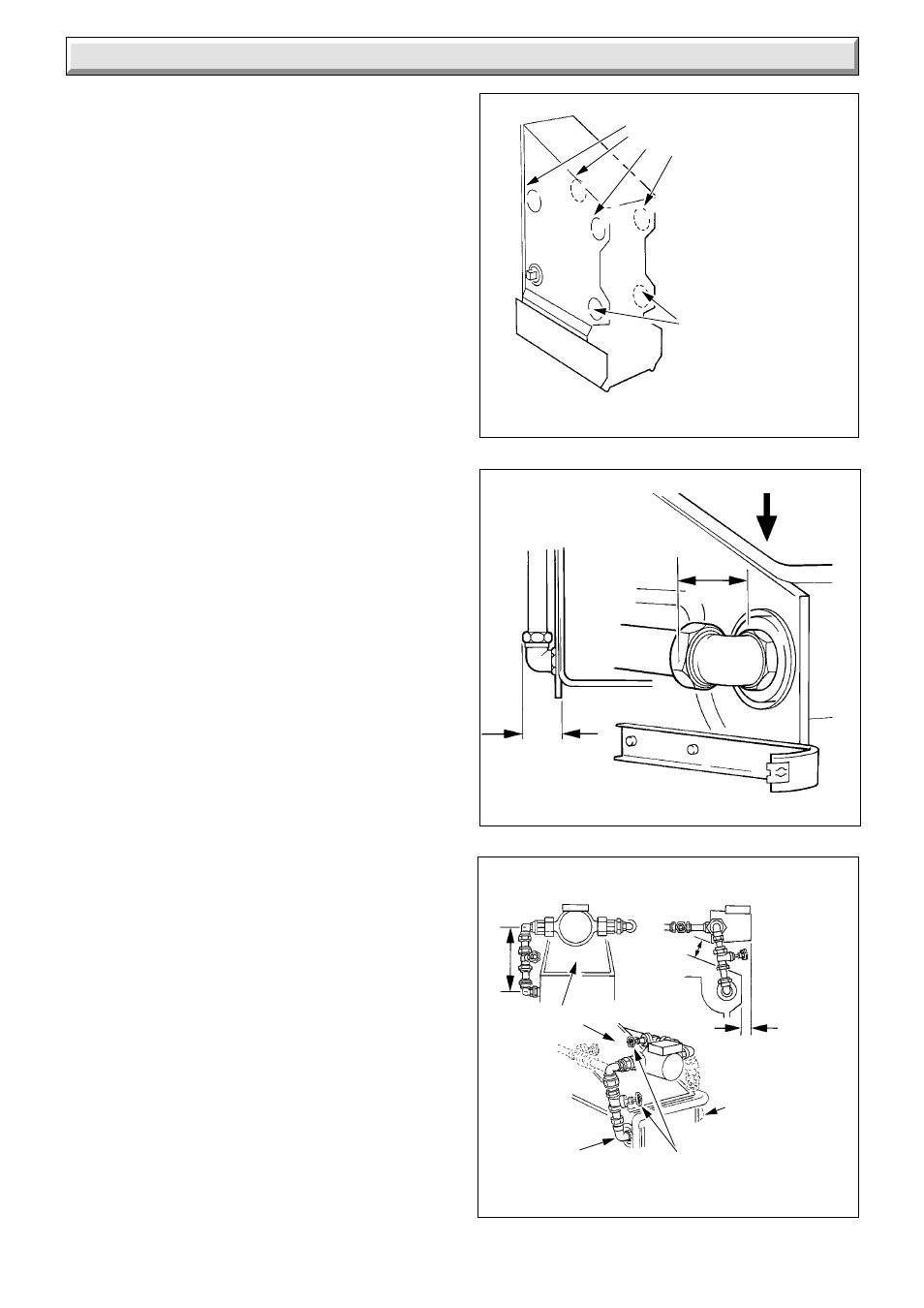

When suitable installation clearances are available, position

the boiler in readiness to connect pipework.

If suitable clearances are not available it will be necessary to

preplumb the gas and water connections before positioning the

boiler.

When the front connections are used it is essential that any

pipework or fittings be assembled as shown in diagram 4.5, that

is, do not stick out more than shown.

Make the water connections to the system pipework.

Make the gas connection to gas supply at the union gas service

cock. Test the complete gas installation for soundness and

purge in accordance with the current issue of BS6891.

4.6 Pump within Boiler Casing

If the pump is to be fitted inside the boiler casing connect it as

shown to either of the upper front flow connections, see diagram

4.6.

There must be sufficient clearance “X” between the pump body

and the flueway cleaning door to allow removal of the door.

Dependent upon the type of pump used, the flow pipe

arrangements and pump may require titling backwards to clear

the casing door.

4.7 Flue Connection

The flue should be 125mm (5in) nominal diameter, refer to

Section 3 and diagram 1.1.

Fix and seal the flue to the hood in accordance with normal

practice.

Diagram 4.6

Diagram 4.4

WATER CONNECTIONS FULLY

PUMPED SYSTEMS

PUMP CLEARANCES

0874

ALTERNATIVE FLOW

POSITIONS

ALTERNATIVE

RETURN

POSITIONS

With distributor

tube (not shown)

Clearance 'X' must be left to enable cleaning

door removal and boiler servicing

'X'

FLUEWAY

CLEANING

DOOR

ALTERNATIVE

R.H. FLOW

CONNECTION

ISOLATING

VALVES

L.H. FLOW

CONNECTION

175

(7)

35 (1

3

/

8

)

0875

Diagram 4.5

PIPEWORK

CASING CLEARANCES

VIEW ON ARROW 'A'

1524

'A'

57 MAX.

(2

1

/

4

in.)

BOILER

57 MAX.

(2

1

/

4

in.)

4 Installation